Bentonite, a highly absorbent clay primarily composed of montmorillonite, plays a crucial role in civil engineering for soil stabilization, foundation sealing, and as a barrier material. Its effectiveness is heavily dependent on particle size and uniformity, making the grinding process a critical step. Selecting the right grinding mill is paramount for achieving the desired material properties efficiently and cost-effectively. This article explores five predominant types of grinding mills used for processing bentonite in soil stabilization applications, detailing their operational principles, advantages, and ideal use cases.

Raymond Mills, specifically the MTM Series, are a traditional and widely used choice for medium-fine grinding of bentonite. They are renowned for their reliability and relatively simple operation.

The main motor drives the central shaft to rotate via a gearbox. The swing arm assembly, from which the grinding roller is suspended, forms a pivot point. A shovel system feeds the material into the gap between the grinding roller and the grinding ring. Centrifugal force causes the roller to swing outward, pressing against the ring and exerting a rolling pressure that crushes the material. An airflow system through a classifier separates the fine powder, which is then collected, while coarse particles fall back for regrinding.

Ideal for small to medium-scale projects where the required bentonite fineness is not extremely high and operational simplicity is valued.

While not as common as other mills for pure bentonite, HPGRs are gaining traction for their exceptional energy efficiency in comminution.

Material is fed between two counter-rotating rolls. One roll is fixed, and the other is movable, powered by a hydraulic system that applies immense pressure (typically 50-350 MPa). The material is crushed by this inter-particle compression, resulting in a product with a high proportion of fines and microcracks, reducing the energy needed for subsequent processing steps.

Best suited as a pre-crushing or primary grinding stage before a finer grinding mill, especially in large-scale operations focused on minimizing overall energy costs.

The ball mill is a workhorse of the grinding industry, capable of handling a wide variety of materials and producing a consistent, though sometimes less energy-efficient, product.

A rotating cylindrical shell, partially filled with grinding media (typically steel balls), receives the feed material. As the shell rotates, the balls are lifted and then cascade down, impacting and abrading the material to reduce its size. The ground product is discharged through discharge grates, with the final fineness controlled by the retention time and size of the grinding media.

Excellent for large-scale production of bentonite powder or slurry where extreme fineness is not the primary goal but high throughput is critical.

For advanced soil stabilization applications requiring the highest levels of fineness and reactivity, ultrafine grinding mills are the optimal solution. Our company’s SCM Ultrafine Mill is a standout in this category, engineered to produce micron and sub-micron level bentonite powders.

The SCM Mill operates on a layered grinding principle. The main motor drives a multi-layer grinding ring to rotate. Material is fed into the grinding chamber and, under centrifugal force, is dispersed evenly into the grinding track. It is then compressed and crushed by rollers. The process repeats over multiple layers, ensuring progressive and thorough grinding. A built-in turbo classifier ensures precise particle size cut-off, and a pulse dust collector achieves high collection efficiency.

| Model | Output (t/h) | Main Motor Power (kW) | Feed Size (mm) | Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | ≤20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | ≤20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | ≤20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | ≤20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | ≤20 | 325-2500 |

The SCM Ultrafine Mill is the perfect choice for producing high-performance bentonite for critical civil engineering projects where maximum swell volume, low permeability, and superior reactivity are non-negotiable, such as in landfill liners, vertical barriers, and advanced soil amendment.

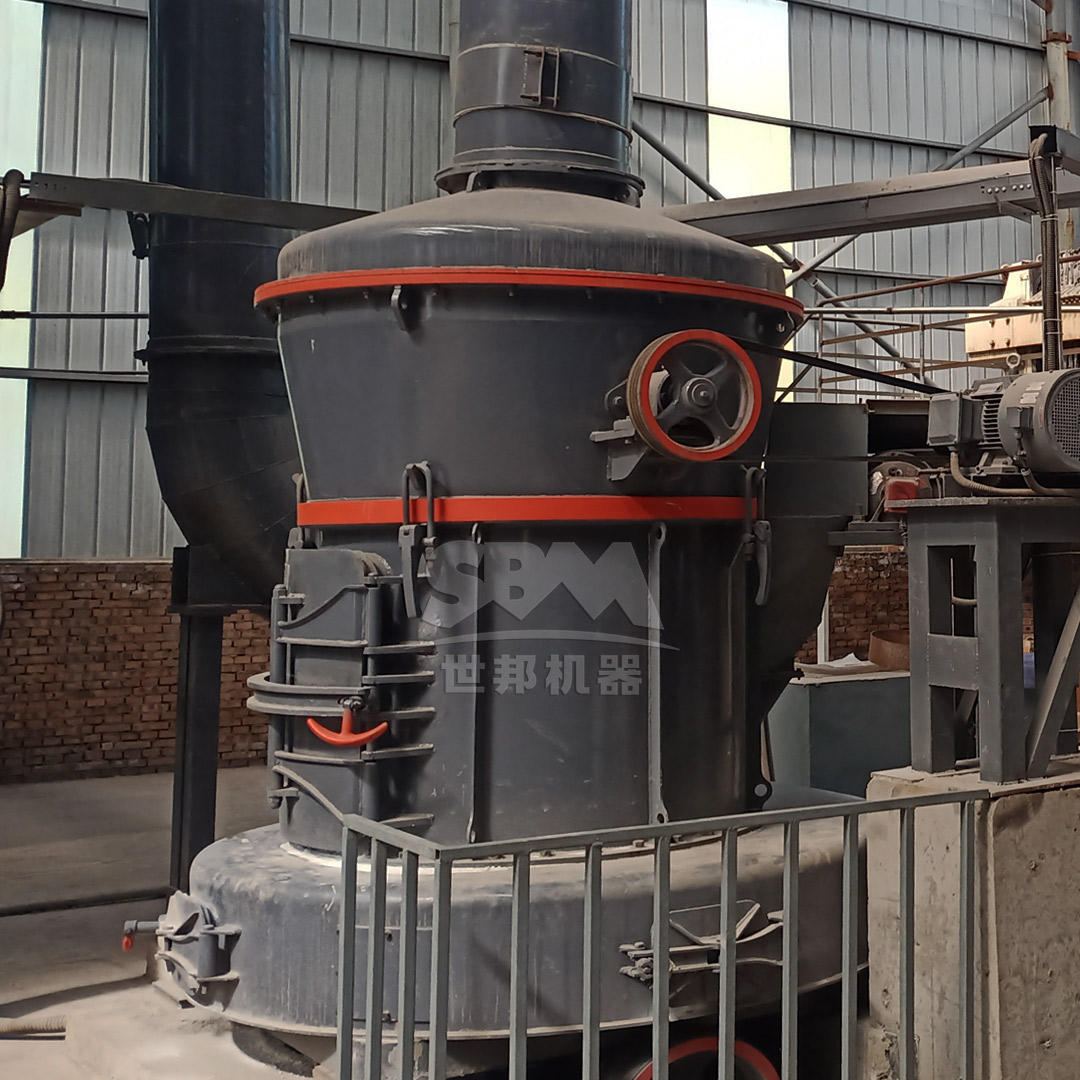

Vertical Roller Mills (VRMs) represent a modern, integrated, and highly efficient grinding solution, combining crushing, grinding, drying, and classifying in a single unit.

Material is fed onto the center of a rotating grinding table. Centrifugal force spreads it evenly under the grinding rollers. The rollers exert pressure, crushing the material into a fine bed. Hot air blown from the bottom dries the material and carries the fine particles to a classifier integrated at the top of the mill. Coarse particles fall back onto the table for further grinding.

Our MTW Series Trapezium Mill is another excellent VRM option, featuring advanced design elements like combined wear-resistant blades, curved air channels for reduced energy loss, and a centralized gear drive with 98% transmission efficiency. Its models, such as the MTW215G, offer high capacities up to 45 t/h, making it suitable for large-scale bentonite processing projects that require a balance of high output and good fineness control.

VRMs are ideal for medium to large-scale production of bentonite powder, especially when dealing with slightly moist feed material or when space and energy efficiency are major concerns. They are a versatile and robust solution for modern soil stabilization material production plants.

The selection of a bentonite grinding mill is a strategic decision that directly impacts the quality, cost, and efficiency of soil stabilization projects. From the traditional reliability of Raymond and Ball Mills to the high-energy efficiency of HPGRs, and onto the advanced capabilities of Ultrafine Mills and integrated Vertical Roller Mills, each technology offers distinct benefits.

For projects demanding the ultimate in bentonite performance, our SCM Ultrafine Mill provides unparalleled fineness and efficiency. For large-scale operations prioritizing integrated processing and energy savings, our MTW Series Trapezium Mill or LM Vertical Mill present superior, modern solutions. Understanding the specific requirements of your project is key to selecting the most appropriate grinding technology to ensure the success and durability of your civil engineering endeavors.