The paint and coatings industry relies heavily on the quality and consistency of its raw materials. Among these, kaolin, a naturally occurring clay mineral, is a critical component used as an extender and opacifier. Its performance is intrinsically linked to its particle size distribution and purity. Achieving the optimal fineness and uniformity requires advanced grinding technology. Pendulum roller mills have emerged as a superior solution for kaolin processing, offering unparalleled efficiency, precision, and reliability in producing the fine powders essential for high-quality paint formulations.

Kaolin enhances several key properties in paint. It improves opacity and brightness, controls gloss, increases pigment volume concentration (PVC), and provides better suspension for other solid components. However, these benefits are only fully realized when the kaolin is ground to a specific and consistent fineness. Coarse particles can lead to poor opacity, reduced gloss control, and a rough finish. Therefore, the grinding process is not merely about size reduction but about achieving a precise particle size distribution (PSD) that maximizes performance.

Grinding kaolin presents unique challenges. Its abrasive nature can cause rapid wear on grinding components, leading to increased maintenance costs and potential contamination of the product. Furthermore, the process must be energy-efficient to be economically viable and must operate within strict environmental guidelines regarding dust and noise emissions. Traditional grinding systems like ball mills or Raymond mills often struggle to meet all these requirements simultaneously.

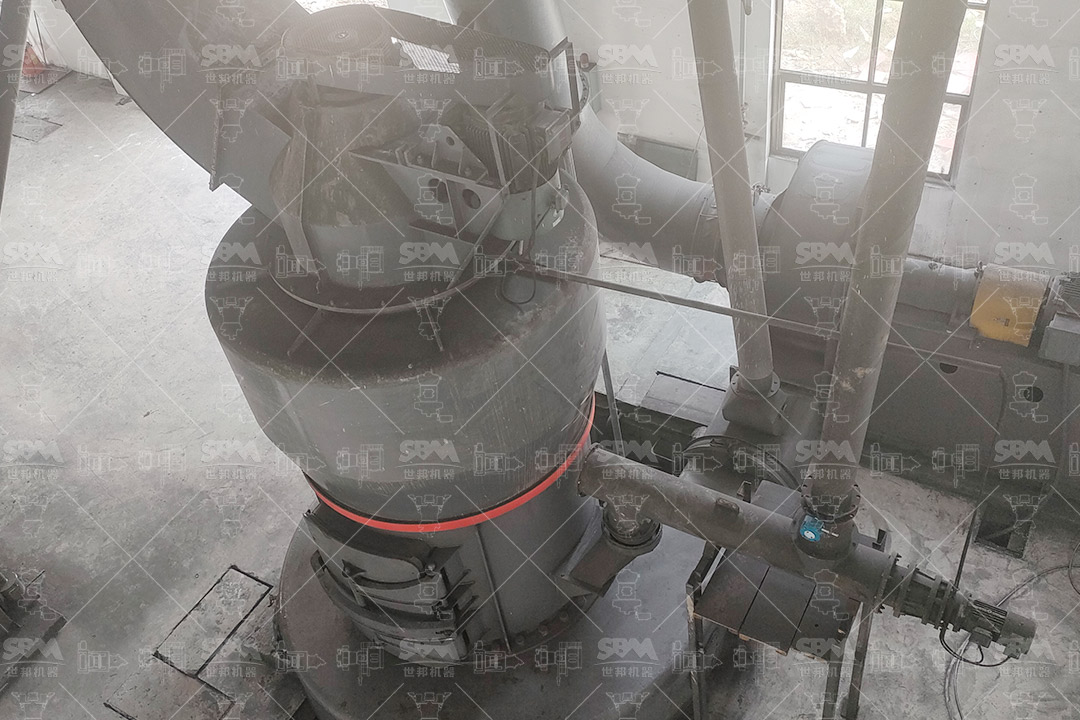

Pendulum roller mills represent a significant technological advancement over traditional grinding equipment. Their design is specifically suited to handling abrasive materials like kaolin while delivering high efficiency and precise particle size control.

The fundamental operation involves a suspended grinding roller assembly that rotates around a central axis while simultaneously rotating on its own axis. Centrifugal force presses the rollers against a stationary grinding ring. Feed material is scooped by a blade and thrown into the path of these rollers, where it is subjected to intense compression and shear forces, resulting in comminution. An integrated air classifier immediately separates the fine particles from the coarse ones, which are returned for further grinding. This closed-circuit system ensures high efficiency and a tightly controlled PSD.

| Key Grinding Technology Comparison | Ball Mill | Traditional Raymond Mill | Modern Pendulum Roller Mill |

|---|---|---|---|

| Energy Efficiency | Low | Medium | High |

| Wear on Abrasive Materials | High | High | Medium (Mitigated by advanced designs) |

| Particle Size Control (PSD) | Broad | Moderate | Narrow and Precise |

| System Footprint | Large | Medium | Compact |

| Noise & Dust Emissions | High | Medium | Low |

For paint manufacturers seeking to produce the highest quality kaolin powders with exceptional fineness and brightness, we highly recommend our SCM Ultrafine Mill. This machine is engineered to excel in the most demanding ultrafine grinding applications.

The SCM series is capable of achieving an impressive output fineness ranging from 325 to 2500 mesh (D97 ≤ 5μm), making it ideal for premium paint grades where superior opacity and smoothness are paramount. With a capacity of 0.5 to 25 tons per hour, it can be scaled to meet both pilot-scale and full production requirements.

| SCM Series Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Output Fineness (mesh) |

|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 325-2500 |

For applications requiring high capacity and excellent efficiency in the coarser to medium-fine range (30-325 mesh), our MTW Series Trapezium Mill presents an outstanding alternative. It is a robust and versatile workhorse for modern kaolin processing plants.

This European-style grinder handles feed sizes up to 50mm and delivers capacities from 3 to 45 tons per hour. Its curved air duct and overall transmission system are designed for minimal energy loss and high grinding efficiency.

Investing in advanced grinding technology like the SCM or MTW series mills translates directly to a stronger bottom line. The significant reduction in energy consumption lowers operating costs. The extended lifespan of wear parts and reduced frequency of maintenance interventions decrease downtime and spare parts inventory costs. Most importantly, the consistent production of high-value, in-spec kaolin powder enhances the quality and competitive edge of the final paint products, allowing manufacturers to command better prices in the market.

The pursuit of excellence in paint production is inextricably linked to the quality of its raw materials. Optimizing the kaolin grinding process with modern pendulum roller mill technology is no longer a luxury but a necessity for competitive and sustainable manufacturing. Our SCM Ultrafine Mill and MTW Series Trapezium Mill offer tailored solutions to meet the diverse needs of the industry, from ultrafine premium products to high-volume standard grades. By focusing on efficiency, precision, durability, and environmental protection, these technologies empower paint producers to achieve new levels of product quality and operational performance.