The refractory industry in Asia is experiencing rapid growth, driven by expanding steel, cement, and glass manufacturing sectors. High-quality refractory bricks are essential for lining high-temperature industrial furnaces, and their performance heavily depends on the quality of raw materials, particularly bauxite. Pulverizing bauxite to the correct fineness and particle size distribution is a critical step in ensuring the final product’s density, thermal stability, and mechanical strength. Selecting the optimal pulverizing equipment is, therefore, not just a matter of operational efficiency but a strategic decision impacting product quality and market competitiveness.

Asian markets present unique challenges, including varying raw material characteristics, stringent environmental regulations, and a strong emphasis on cost-effectiveness. This article explores the key considerations for selecting bauxite pulverizers and highlights advanced technological solutions tailored for producers targeting these dynamic markets.

Bauxite, the primary ore for aluminum production, is also a crucial raw material for high-alumina refractory bricks. Its abrasive nature and often variable hardness demand robust and efficient grinding technology. The ideal pulverizer must achieve several objectives:

The fineness and particle size distribution of bauxite powder directly influence the packing density and sintering behavior of refractory bricks. A narrow particle size distribution ensures better compaction and fewer voids, leading to bricks with higher strength and superior resistance to thermal shock and corrosion. Equipment with high-precision classification systems is paramount.

Grinding is an energy-intensive process. With rising energy costs across Asia, mills that offer higher throughput with lower specific energy consumption provide a significant competitive advantage. This is measured in kWh per ton of finished product.

Bauxite is highly abrasive. Pulverizers must be constructed with wear-resistant materials in critical components like rollers, grinding rings, and liners to ensure long service life and minimize downtime for maintenance and part replacement.

Asian countries are increasingly enforcing strict environmental standards regarding dust emissions and noise pollution. A modern pulverizing system must incorporate highly efficient dust collection and noise reduction technologies to operate sustainably and avoid regulatory penalties.

Production requirements can vary. A mill that can handle a range of feed sizes and easily adjust its output fineness offers greater operational flexibility to meet different product specifications.

Several types of grinding mills are used in mineral processing. However, not all are equally suited for the demanding task of pulverizing abrasive bauxite to refractory-grade fineness.

Traditional ball mills are versatile but often less efficient for fine grinding applications. Their energy efficiency drops significantly as the target fineness increases. Furthermore, wear on liners and balls can be substantial with abrasive materials like bauxite, leading to high maintenance costs and potential iron contamination, which is detrimental to refractory quality.

These are common for medium-fine grinding. While improvements have been made, traditional designs can struggle with achieving very fine sizes (e.g., >325 mesh) efficiently and may have issues with wear and system airflow.

VRMs have become the industry standard for many grinding applications due to their superior efficiency. They operate by grinding material between a rotating table and rollers. Their advantages include significantly lower energy consumption (30-50% less than ball mills), excellent drying capability (if needed), and lower noise levels. Their ability to handle feed sizes up to 50mm also simplifies the crushing circuit.

For applications requiring extremely fine powders (e.g., 2500 mesh or D97 ≤ 5μm), specialized ultrafine mills are required. These mills integrate high-speed impact and precise air classification to produce superfine powders, which can be used to enhance the sintering activity and density of advanced refractories.

Based on the demanding requirements of bauxite processing—abrasiveness, need for precise grading, and energy efficiency—two of our flagship products stand out as ideal solutions for modern refractory plants in Asia.

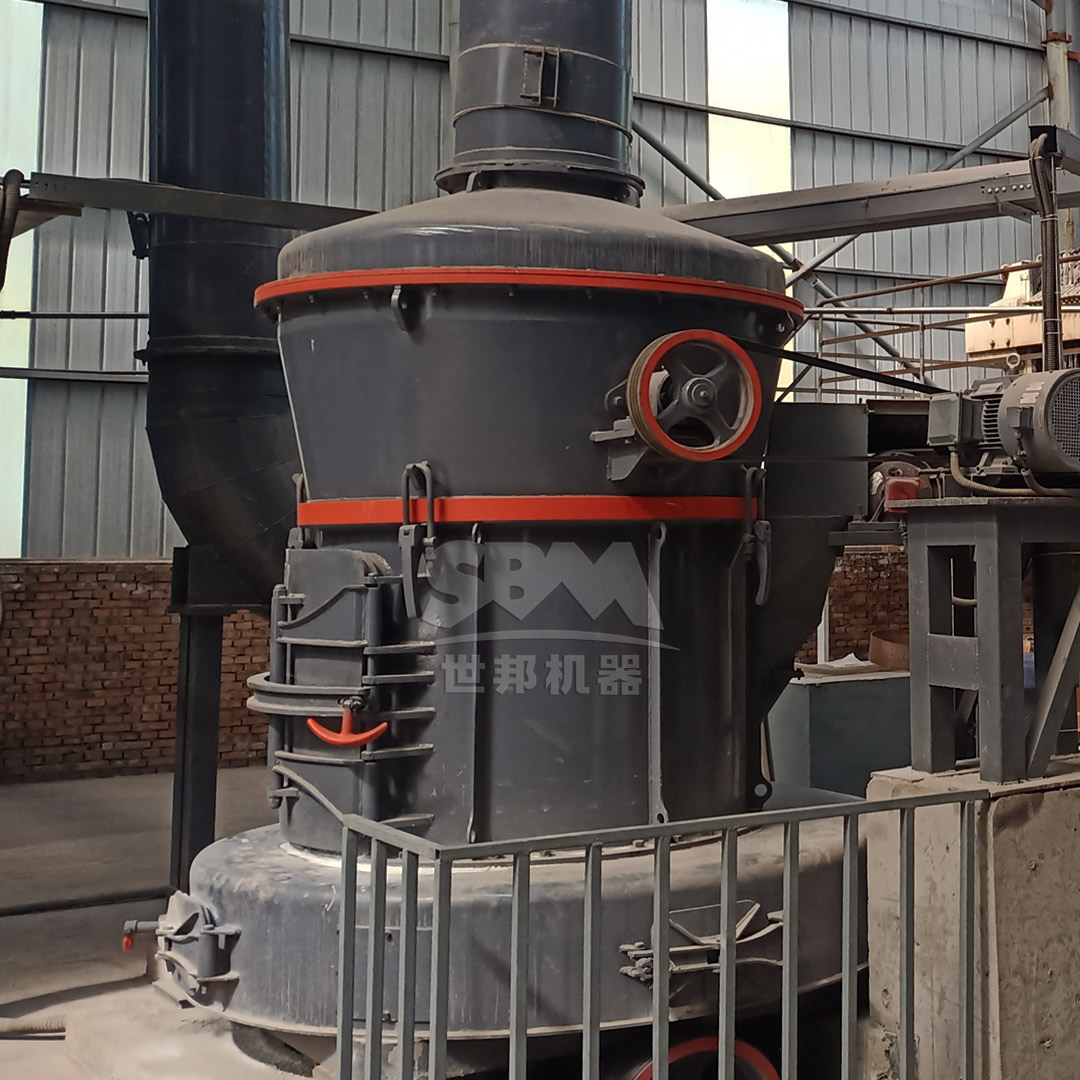

For most refractory applications requiring bauxite powder in the range of 30-325 mesh (600-45μm), the MTW Series Trapezium Mill represents a perfect balance of performance, reliability, and cost-effectiveness. It is engineered to tackle the challenges of grinding hard and abrasive materials.

Why it excels for bauxite:

| Model | Feed Size (mm) | Output Fineness (mesh) | Capacity (t/h) | Main Motor Power (kW) |

|---|---|---|---|---|

| MTW175G | <40 | 30-325 | 9.5-25 | 160 |

| MTW215G | <50 | 30-325 | 15-45 | 280 |

The MTW215G model, with its capacity of up to 45 tons per hour, is particularly suited for large-scale refractory production facilities looking to supply major industrial clients across Asia.

For manufacturers producing high-performance, specialty refractory products where ultra-fine bauxite powder is required to improve sintering density and mechanical properties, the SCM Ultrafine Mill is the undisputed technology leader.

Why it excels for advanced bauxite processing:

| Model | Feed Size (mm) | Output Fineness (mesh) | Capacity (t/h) | Main Motor Power (kW) |

|---|---|---|---|---|

| SCM1000 | ≤20 | 325-2500 | 1.0-8.5 | 132 |

| SCM1680 | ≤20 | 325-2500 | 5.0-25 | 315 |

The SCM series allows refractory innovators to develop new, superior products, giving them a critical edge in competitive Asian markets.

The selection of bauxite pulverization equipment is a cornerstone of successful refractory brick production. For Asian manufacturers, the decision must balance performance, operational cost, compliance, and the ability to produce a consistently high-quality product.

While traditional mills like ball mills still have their place, the future lies in adopting more efficient and precise technologies. The MTW Series European Trapezium Mill offers an ideal solution for standard to high-capacity production of quality bauxite powder, while the SCM Series Ultrafine Mill opens the door to innovation and premium product segments.

By investing in the right grinding technology, refractory producers can optimize their entire production process, reduce their environmental footprint, and solidify their position in the fast-growing Asian market.