The semiconductor industry operates at the nanoscale, where material purity and consistency are not just desirable attributes but absolute necessities. Quartz, with its exceptional thermal stability, electrical insulation properties, and chemical inertness, serves as a foundational material in semiconductor fabrication. It is used in crucibles for silicon crystal growth, as components in plasma etching chambers, and in various high-temperature processing equipment. The journey from raw quartz to semiconductor-grade material requires precision grinding technology that can achieve sub-micron particle sizes while maintaining absolute purity and preventing contamination.

Traditional grinding methods often introduce metallic contaminants from wear parts, create inconsistent particle distributions, or generate excessive heat that can alter material properties. These limitations become critical bottlenecks in semiconductor supply chains, where a single impurity particle can render an entire wafer useless. Modern quartz roller mills have been specifically engineered to overcome these challenges, providing the semiconductor industry with materials that meet its exacting standards.

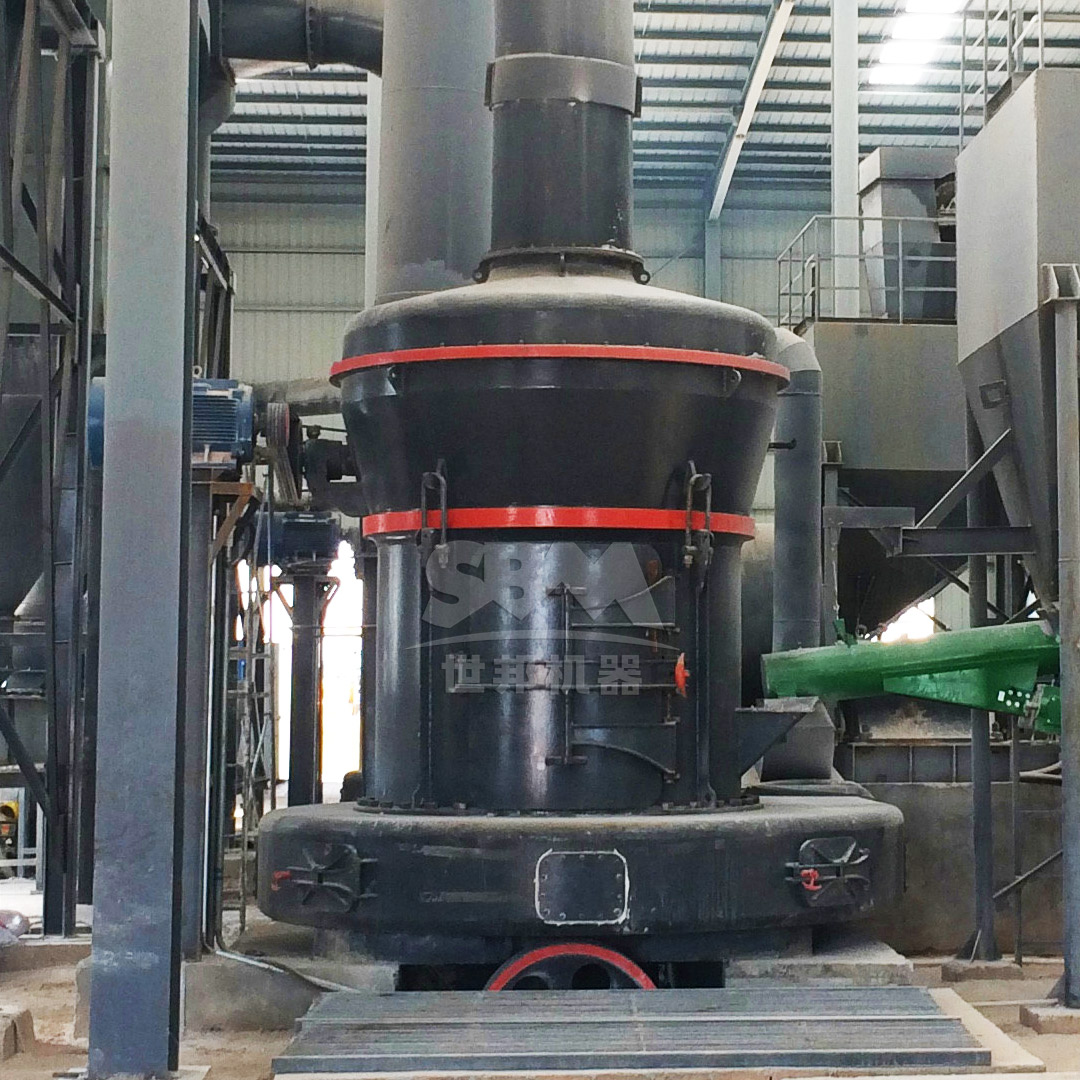

Quartz roller mills employ sophisticated mechanical principles to achieve the delicate balance between particle size reduction and contamination control. Unlike conventional ball mills that rely on impact and attrition through random media collisions, roller mills utilize controlled compression forces between rotating grinding elements. This method generates significantly less heat and minimizes the introduction of foreign particles from grinding media wear.

The heart of these systems features precision-engineered rollers made from specialized materials that match the hardness of quartz while being chemically inert. These rollers apply controlled pressure to quartz particles as they pass between rotating surfaces, creating a shearing action that cleaves particles along their natural crystalline boundaries. This results in more uniform particle shapes and size distributions compared to the random fracturing that occurs in impact-based mills.

Beyond the grinding mechanism itself, advanced classification technology plays an equally crucial role in achieving semiconductor-grade quartz powders. Modern mills incorporate high-precision air classifiers that use centrifugal forces and airflow dynamics to separate particles based on size with remarkable accuracy. These systems can consistently achieve cuts in the D97 ≤ 5μm range, ensuring that oversized particles are continuously returned to the grinding zone for further processing.

The classification process occurs in a completely enclosed environment, preventing contamination from ambient air particles while maintaining consistent product quality. Sophisticated sensor arrays monitor particle size distribution in real-time, allowing for automatic adjustments to maintain target specifications throughout production runs.

In semiconductor applications, the grinding equipment itself can become a source of contamination if not properly designed. Quartz roller mills address this challenge through strategic material selection for all components that contact the product. Critical wear parts are manufactured from specialized ceramics, high-chromium alloys, or other materials specifically chosen for their hardness, corrosion resistance, and low tendency to shed particles.

These materials undergo rigorous testing to ensure they can withstand the abrasive nature of quartz without significant wear over extended operational periods. The economic impact of this durability is substantial—reduced maintenance frequency translates to less downtime and lower risk of contamination during component replacement.

Modern quartz milling systems operate as completely sealed environments, maintaining negative pressure to prevent the escape of fine particles while simultaneously excluding ambient contaminants. This closed-loop design extends beyond the grinding chamber to include the entire material handling system—from raw material intake through final product collection.

Advanced filtration systems with HEPA-grade filters capture particles that escape the primary collection cyclones, ensuring that exhaust air meets the strictest environmental standards. Meanwhile, automated cleaning systems minimize cross-contamination between production batches, a critical feature when producing multiple quartz grades or transitioning between different material types.

For semiconductor applications requiring the finest quartz powders, the SCM Ultrafine Mill represents the cutting edge of grinding technology. This system achieves remarkable fineness levels of 325-2500 mesh (D97 ≤ 5μm) while maintaining exceptional energy efficiency—operating at 30% lower energy consumption compared to conventional jet mills with twice the production capacity.

The SCM series incorporates several innovations specifically beneficial for semiconductor material processing:

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Feed Size (mm) | Product Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 0-20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 0-20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 0-20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 0-20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 0-20 | 325-2500 |

The operational principle involves a main motor driving multiple layers of grinding rings in a rotational motion. Quartz material is dispersed into the grinding path by centrifugal force, undergoing progressive compression and shearing through multiple grinding stages. The final product is collected through a combination of cyclone separators and pulse dust collection systems, ensuring maximum yield of in-specification material.

For semiconductor manufacturers seeking integrated grinding solutions, the LUM Ultra-fine Vertical Mill offers exceptional performance in a compact footprint. This system combines grinding, classification, and transportation in a single unit, reducing the potential contamination points that exist in multi-equipment processing lines.

Key advantages of the LUM series for quartz processing include:

| Model | Main Motor Power (kW) | Processing Capacity (t/h) | D97 Particle Size (μm) |

|---|---|---|---|

| LUM1525 | 220-250 | 1.6-11.5 | 5-30 |

| LUM1632 | 280-315 | 2-13.5 | 5-30 |

| LUM1836 | 355-400 | 2.3-15 | 5-30 |

The LUM mill operates through a combination of roller compression grinding and efficient air classification. Material is fed into the grinding chamber where rollers apply precise pressure to quartz particles, creating the desired size reduction. An integrated airflow system carries the ground material to the classification zone, where precisely sized particles are separated. Oversized material returns to the grinding zone for further processing, while metallic impurities are automatically removed through a scraper system.

Modern quartz roller mills incorporate comprehensive monitoring systems that track critical parameters throughout the grinding process. Laser particle size analyzers provide real-time feedback on product size distribution, allowing for immediate adjustments to maintain specifications. Temperature sensors ensure that the grinding process remains within optimal ranges to prevent thermal degradation of the quartz material.

These monitoring capabilities are integrated with automated control systems that can make fine adjustments to roller pressure, classifier speed, and feed rates without operator intervention. The result is consistent product quality that meets the strict statistical process control requirements of semiconductor manufacturers.

For semiconductor applications, documentation of material history and processing parameters is as important as the material specifications themselves. Advanced quartz milling systems include data logging capabilities that record all critical process parameters for each production batch. This information becomes part of the material certification package, providing semiconductor manufacturers with the traceability they require for their quality systems.

These systems can interface with manufacturing execution systems (MES) to provide real-time production data and alert operators to any deviations from established parameters. This level of integration ensures that quartz materials maintain their certification status throughout the supply chain.

While the initial investment in advanced quartz roller mill technology may be higher than conventional grinding equipment, the total cost of ownership is significantly lower. The exceptional wear resistance of critical components extends maintenance intervals, reducing both parts replacement costs and production downtime. Energy efficiency improvements of 30-50% compared to traditional mills translate to substantial operational savings, particularly in energy-intensive fine grinding applications.

Perhaps most importantly for semiconductor manufacturers, the consistency and purity of the finished product reduce downstream processing issues and improve yields in semiconductor fabrication. The value of this reliability far exceeds the incremental equipment costs when considered in the context of multi-million dollar semiconductor production lines.

Modern quartz roller mills are available in a range of sizes and configurations to match production requirements from laboratory-scale development to full-scale manufacturing. This scalability allows semiconductor material suppliers to use the same technology platform from R&D through production, ensuring consistency as processes are scaled.

The flexibility of these systems extends to their ability to process different quartz types and grades with minimal changeover time. Quick-adjustment mechanisms allow operators to transition between product specifications without extensive recalibration, improving overall equipment utilization in multi-product facilities.

The evolution of quartz roller mill technology continues to address the increasingly stringent requirements of the semiconductor industry. Research and development efforts are focusing on several key areas:

As semiconductor features continue to shrink and new materials are introduced, quartz roller mill technology will continue to evolve to meet the purity and precision requirements of next-generation electronic devices.

Quartz roller mills represent a critical enabling technology for the semiconductor industry, providing the high-purity materials required for advanced electronic devices. Through precision engineering, advanced classification systems, and comprehensive contamination control measures, these grinding systems deliver consistent, sub-micron quartz powders that meet the industry’s most demanding specifications.

The continued development of quartz milling technology will play an essential role in supporting the semiconductor industry’s roadmap, enabling the production of ever-smaller, more powerful electronic devices. As material requirements become more stringent, the innovations in roller mill design and operation will ensure that the semiconductor industry has access to the high-purity quartz materials it needs to continue driving technological progress.