The selection of appropriate talc powder processing equipment is critical for manufacturers in the adhesives and sealants industry. Talc, a hydrated magnesium silicate mineral, serves as an essential functional filler that enhances product performance through improved reinforcement, rheological control, and cost optimization. The processing machinery must deliver precise particle size distribution, maintain chemical purity, and ensure consistent production quality while operating efficiently. This comprehensive guide examines the key factors to consider when selecting talc processing equipment specifically for adhesive and sealant applications.

Before selecting processing equipment, manufacturers must understand the specific talc requirements for their adhesive and sealant formulations. Talc contributes multiple functional benefits including reinforcement, viscosity modification, sag resistance, and improved thermal stability. The effectiveness of these properties depends heavily on particle size distribution, surface area, and particle morphology.

For most adhesive and sealant applications, talc fillers typically range from 45 microns (325 mesh) to 5 microns (2500 mesh). Coarser particles (45-20 microns) provide bulk filling and cost reduction, while finer particles (20-5 microns) deliver enhanced reinforcement and improved surface finish. The optimal particle size distribution depends on the specific application requirements:

| Application Type | Recommended Particle Size | Functional Benefits |

|---|---|---|

| Construction Sealants | 45-20 microns | Sag resistance, extrusion control |

| Industrial Adhesives | 20-10 microns | Reinforcement, viscosity stability |

| Electronic Grade Sealants | 10-5 microns | Surface smoothness, fine detail |

Talc used in adhesives and sealants must meet strict chemical purity standards, particularly regarding iron content and other contaminants that could affect product stability or cause discoloration. Processing equipment must be constructed with materials that prevent contamination during grinding operations.

Selecting the right talc processing machinery involves evaluating multiple technical parameters to ensure optimal performance in adhesive and sealant production environments.

The equipment must deliver precise and consistent particle size distribution with narrow variance. Look for machines with advanced classification systems that can maintain tight tolerances throughout production runs. The ability to adjust fineness quickly and reliably is essential for manufacturers producing multiple product grades.

Processing capacity requirements vary significantly based on production volume. Small to medium operations may require throughput of 1-10 tons per hour, while large-scale manufacturers may need equipment capable of 25+ tons per hour. Consider both current needs and future expansion when selecting equipment size.

Grinding operations typically account for a significant portion of manufacturing energy consumption. Modern equipment should incorporate energy-saving technologies such as optimized grinding mechanics, efficient classification systems, and intelligent control systems that minimize power consumption while maintaining output quality.

Equipment construction materials and design must prevent metallic contamination during processing. Ceramic linings, specialized wear materials, and effective sealing systems are essential for maintaining product purity, particularly in high-value adhesive applications.

The ideal processing system should accommodate variations in raw material characteristics and enable quick changes between different product specifications. Quick-adjustment mechanisms for particle size control and easy maintenance access contribute significantly to overall operational efficiency.

Various grinding technologies are available for talc processing, each with distinct advantages for specific applications in the adhesives and sealants industry.

For applications requiring very fine talc powders (5-45 microns), ultrafine grinding mills offer superior performance. These systems combine high-intensity grinding with precision air classification to produce consistently fine particles with narrow size distribution.

Our SCM Ultrafine Mill represents an excellent solution for high-quality talc production for adhesives and sealants. With output fineness ranging from 325 to 2500 mesh (D97≤5μm), this machine delivers precisely the particle characteristics needed for premium adhesive formulations. The vertical turbine classifier ensures accurate particle size切割 with no coarse powder contamination, while the special material rollers and grinding rings provide extended service life. For adhesive manufacturers requiring consistent ultrafine talc powder, the SCM series offers energy efficiency 30% better than jet mills with doubled production capacity.

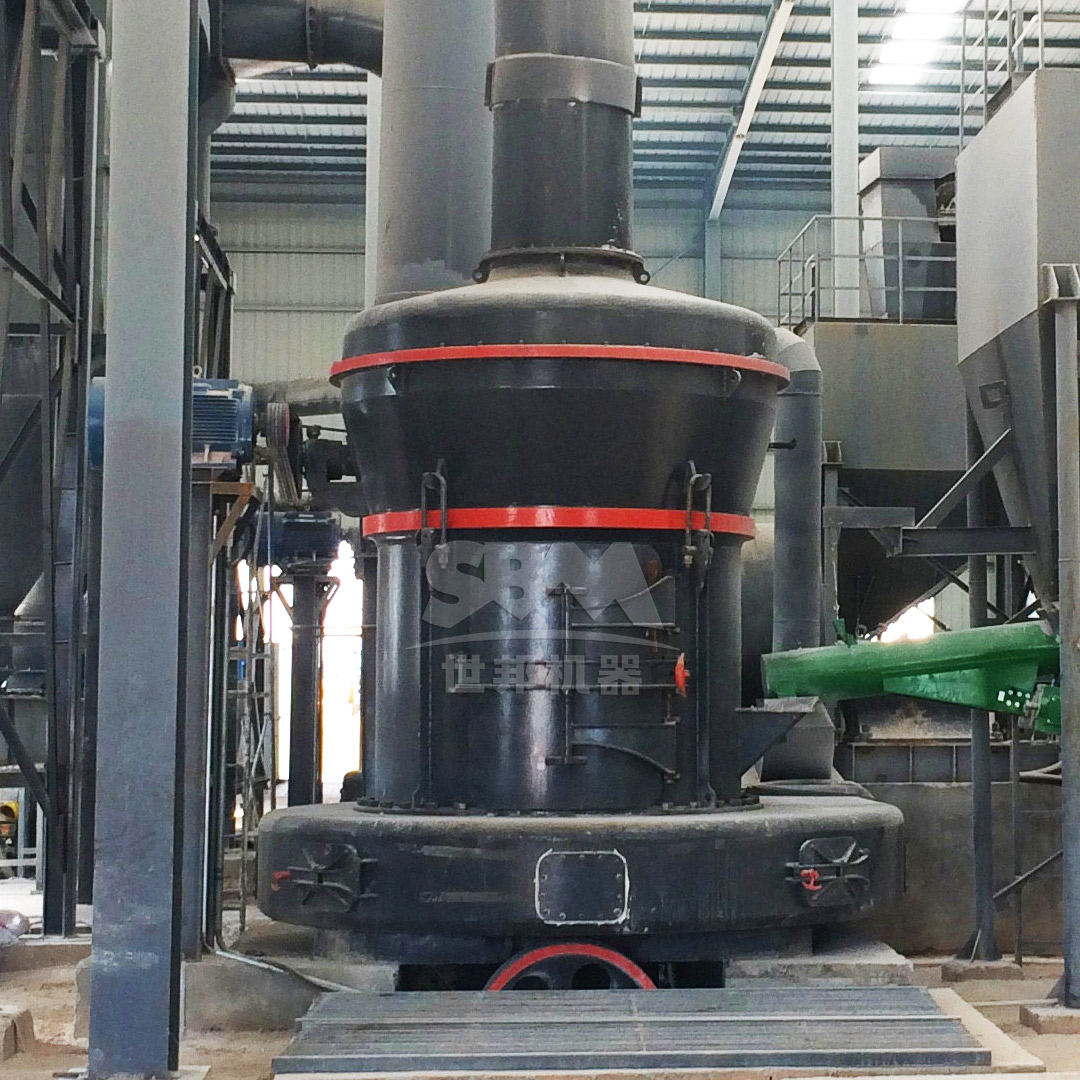

Vertical roller mills provide efficient processing for medium to fine talc powders (45-600 microns). These systems offer high capacity in a compact footprint and are particularly suitable for large-volume production requirements.

Our LM Series Vertical Roller Mill provides an integrated solution combining crushing, grinding, and separation functions in a single unit. With output fineness from 30 to 325 mesh (special models to 600 mesh) and capacity ranging from 3 to 250 tons per hour, this equipment suits various production scales. The intelligent control system enables automatic operation with remote monitoring capabilities, while the fully sealed negative pressure operation ensures dust emissions remain below 20mg/m³. For adhesive manufacturers seeking high-volume production with consistent quality, the LM series offers 30-40% lower energy consumption compared to ball mill systems.

Medium-speed trapezium mills provide a balanced solution for general-purpose talc grinding applications. These machines offer reliable performance with relatively simple operation and maintenance requirements.

Traditional ball mills continue to serve in some talc processing applications, particularly where very high capacity is required and the finest particle sizes are not essential. Modern ball mills incorporate improved lining materials and drive systems for better efficiency.

| Equipment Type | Output Fineness | Capacity Range | Energy Efficiency | Best Applications |

|---|---|---|---|---|

| Ultrafine Mills | 325-2500 mesh | 0.5-25 t/h | High | Premium adhesives, electronic sealants |

| Vertical Roller Mills | 30-600 mesh | 3-250 t/h | Very High | High-volume production, general adhesives |

| Trapezium Mills | 45-325 mesh | 3-45 t/h | Medium-High | Standard adhesives, construction sealants |

| Ball Mills | 0.074-0.8mm | 0.65-450 t/h | Medium | High-capacity, coarse fillers |

Complete talc processing lines require properly integrated auxiliary equipment to ensure optimal system performance.

Consistent and controlled material feeding is essential for stable grinding operation. Vibratory feeders, screw conveyors, or belt feeders should match the main equipment’s capacity and provide reliable material transport without bridging or segregation.

Advanced air classifiers are critical for achieving precise particle size control. Modern classifiers offer adjustable cutting points, high separation efficiency, and stable operation across varying feed conditions.

Effective dust control is essential for both product recovery and environmental compliance. Pulse jet baghouse filters typically provide the necessary collection efficiency for talc applications, with filtration velocities optimized for the specific material characteristics.

Pneumatic conveying systems efficiently transport finished talc powder to storage silos. Design considerations should include minimizing particle degradation during transport and implementing appropriate aeration and discharge systems for reliable material flow.

The total cost of ownership for talc processing equipment extends beyond the initial purchase price to include operational, maintenance, and energy costs over the equipment’s service life.

Equipment costs vary significantly based on capacity, technology level, and degree of automation. Ultrafine grinding systems typically command higher initial investment but may deliver better value through superior product quality and operational efficiency.

Energy consumption represents the largest portion of operating costs for talc grinding. Modern energy-efficient equipment can reduce power consumption by 30-50% compared to conventional technologies, delivering substantial savings over the equipment lifetime.

Wear part consumption and maintenance labor contribute significantly to operating expenses. Equipment with extended wear life, quick-change components, and accessible maintenance points can substantially reduce downtime and maintenance costs.

A comprehensive ROI analysis should consider improved product quality, production efficiency, energy savings, and reduced maintenance costs. Many modern talc processing systems achieve payback periods of 18-36 months through these operational benefits.

Successful implementation of talc processing equipment requires careful planning and execution across multiple project phases.

Thorough site assessment, foundation design, and utility planning ensure smooth equipment installation. Consider space requirements for operation, maintenance access, and future expansion during the layout planning phase.

Proper commissioning includes mechanical verification, control system calibration, and production testing to optimize operating parameters for specific talc feed materials and product requirements.

Comprehensive training for operations and maintenance personnel ensures correct equipment operation, troubleshooting capability, and adherence to safety protocols.

Implement regular monitoring of key performance indicators including energy consumption, production rate, product quality, and maintenance activities to identify optimization opportunities and address issues proactively.

The talc processing industry continues to evolve with emerging technologies and changing market demands.

Integration of IoT sensors, data analytics, and predictive maintenance technologies enables smarter operation, reduced downtime, and optimized performance through continuous process improvement.

Energy efficiency, reduced water consumption, and minimized environmental impact are becoming increasingly important selection criteria for processing equipment, driven by both regulatory requirements and corporate sustainability goals.

New wear-resistant materials, improved classifier designs, and enhanced control systems continue to push the boundaries of processing efficiency, product quality, and equipment reliability.

Selecting the optimal talc powder processing machine for adhesives and sealants requires careful consideration of multiple technical, operational, and economic factors. The specific application requirements, production volume, quality specifications, and budget constraints all influence the ideal equipment selection. By understanding the capabilities of different grinding technologies and following a systematic evaluation process, manufacturers can identify equipment that delivers the necessary performance while optimizing total cost of ownership. As the adhesives and sealants industry continues to evolve toward higher performance products, the importance of advanced talc processing equipment capable of delivering precise particle characteristics will only increase.