The rubber industry has witnessed significant advancements in material science and processing technologies, with barite (barium sulfate) emerging as a critical functional filler for high-performance rubber compounds. The effectiveness of barite in rubber applications is directly proportional to its particle size distribution and purity. Superfine grinding technology has revolutionized the way barite is processed, enabling manufacturers to achieve unprecedented levels of performance in rubber products.

Barite, when ground to ultrafine particle sizes, offers exceptional advantages in rubber compounding. Its high density, chemical inertness, and excellent dispersion characteristics make it an ideal filler for specialized rubber applications. However, achieving the optimal particle size distribution requires sophisticated grinding equipment capable of producing consistent, high-quality powders with precise control over fineness.

Barite serves multiple functions in rubber compounding beyond mere volume extension. Its unique properties contribute significantly to the final product’s performance characteristics:

Ultrafine barite particles, when properly dispersed throughout the rubber matrix, improve tensile strength, tear resistance, and abrasion characteristics. The fine particles act as reinforcement agents, creating a more homogeneous composite material with superior mechanical integrity.

Barite’s natural lubricity and particle morphology enhance compound flow during extrusion and molding operations. This results in reduced processing energy requirements, improved surface finish, and dimensional stability in the final rubber products.

Being chemically inert, barite does not interfere with the vulcanization process or other chemical reactions within the rubber compound. It provides excellent resistance to acids, alkalis, and various chemicals, making it suitable for demanding applications such as chemical-resistant hoses, gaskets, and seals.

With its high specific gravity (4.3-4.6), barite is particularly valuable in applications requiring weight adjustment, such as anti-vibration mounts, balancing weights, and specialized industrial components.

The rubber industry imposes specific requirements on barite fillers that directly influence the selection of grinding equipment:

| Parameter | Requirement for Rubber | Impact on Performance |

|---|---|---|

| Particle Size (D97) | 5-15 μm | Dispersion, mechanical properties |

| Top Cut | < 20 μm | Surface finish, extrusion quality |

| Moisture Content | < 0.5% | Vulcanization, bubble formation |

| Whiteness | > 92% | Color consistency in compounds |

| Oil Absorption | 10-16 g/100g | Compound viscosity, processing |

Rubber compounding demands precise control over particle size distribution. A narrow distribution curve ensures uniform reinforcement throughout the rubber matrix, preventing weak spots and ensuring consistent product quality. The grinding equipment must maintain this distribution consistently throughout production runs.

Rubber compounds are highly sensitive to metallic contamination, which can catalyze unwanted chemical reactions or create weak points in the final product. Grinding systems must be designed to minimize metal-to-metal contact and incorporate effective separation technologies.

Excessive heat generation during grinding can alter the crystalline structure of barite and affect its performance in rubber compounds. Advanced cooling systems and controlled grinding environments are essential for maintaining product quality.

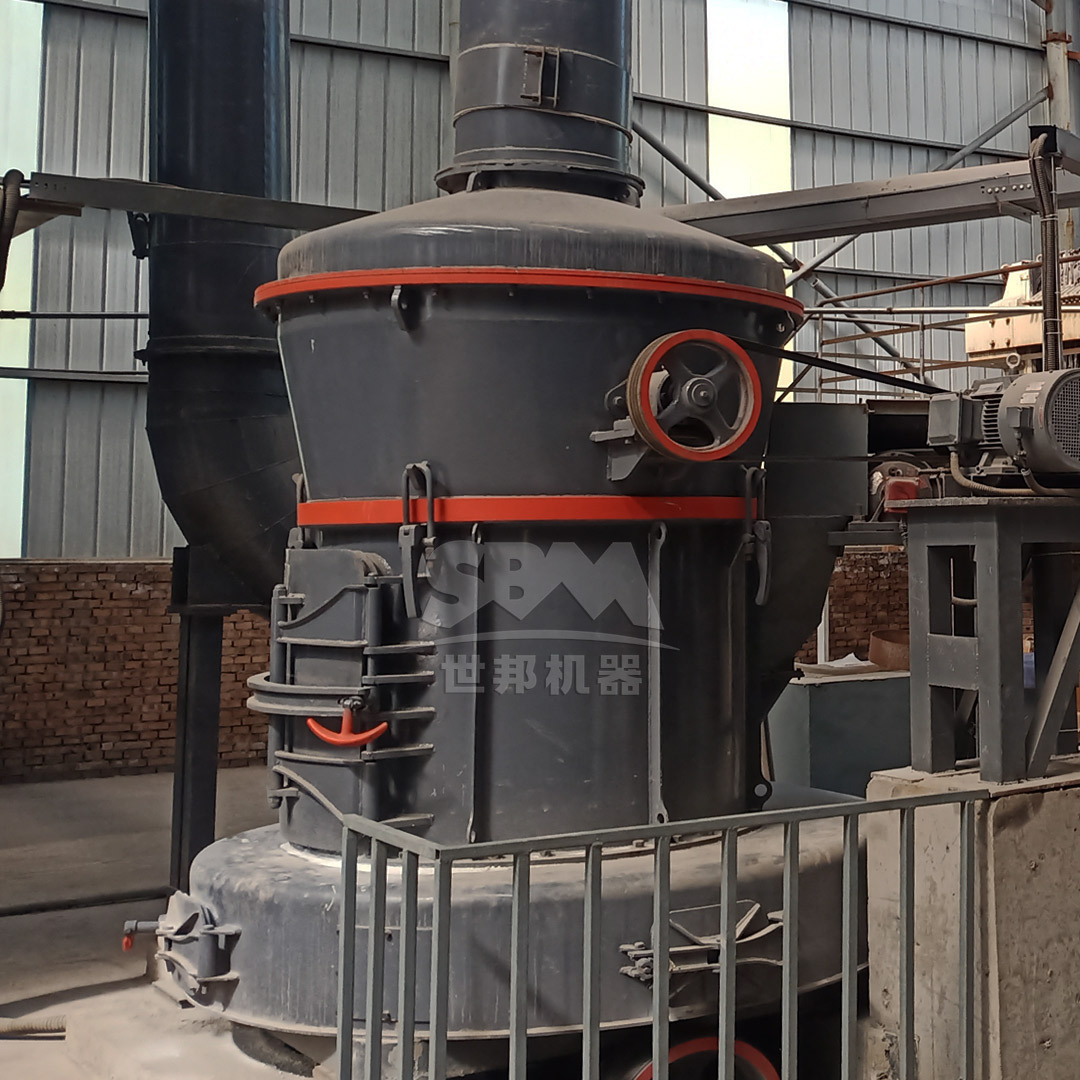

For rubber compounding applications requiring the highest quality barite powders, the SCM Ultrafine Mill represents the state-of-the-art in grinding technology. This advanced mill system has been specifically engineered to meet the demanding requirements of the rubber industry.

The SCM Ultrafine Mill incorporates several technological innovations that make it particularly suitable for barite grinding in rubber compounding:

Precision Particle Size Control: With an output fineness range of 325-2500 mesh (D97 ≤ 5μm), the SCM mill can produce barite powders with the exact specifications required for high-performance rubber compounds. The integrated vertical turbine classifier ensures precise particle size切割, eliminating coarse particles that could compromise rubber product quality.

Energy Efficiency: Operating at 30% lower energy consumption compared to conventional jet mills while delivering twice the capacity, the SCM mill significantly reduces production costs without compromising product quality. This efficiency is particularly valuable in the cost-sensitive rubber industry.

Contamination-Free Design: The specially designed grinding chamber with wear-resistant materials and innovative bearing-free screw design minimizes the risk of metallic contamination, ensuring the barite powder meets the strict purity requirements of rubber compounding.

Based on production requirements typical in the rubber industry, we recommend the following SCM models:

| Model | Processing Capacity | Main Motor Power | Recommended Application |

|---|---|---|---|

| SCM800 | 0.5-4.5 ton/h | 75 kW | Laboratory & small-scale production |

| SCM1000 | 1.0-8.5 ton/h | 132 kW | Medium-scale rubber compounders |

| SCM1250 | 2.5-14 ton/h | 185 kW | Large-scale manufacturing |

For rubber applications that do not require ultrafine barite powders, the MTW Series Trapezium Mill offers an excellent balance of performance and economy. With an output range of 30-325 mesh, this mill is ideal for general-purpose rubber compounds where the highest fineness is not critical.

Anti-Wear Design: The combination shovel blade design significantly reduces maintenance costs, while the curved surface design extends roller life, ensuring consistent product quality over extended operation periods.

Optimized Air Flow: The curved air duct design minimizes energy loss during material transport, improving overall efficiency. The high-strength guard plate protects the air duct working surface, maintaining performance over time.

High Transmission Efficiency: With bevel gear integrated transmission achieving 98% efficiency, the MTW mill delivers reliable performance while reducing installation costs through its space-saving design.

For barite grinding in rubber applications, the MTW138Z and MTW175G models offer the ideal combination of capacity and fineness control for most production scenarios.

Successful barite processing for rubber compounding requires more than just advanced grinding equipment. A comprehensive approach to process control and quality assurance is essential for consistent results.

Raw barite must undergo proper preparation before fine grinding. This includes crushing to appropriate feed size (typically ≤20mm for SCM mills), drying to reduce moisture content, and magnetic separation to remove iron contaminants that could affect rubber compound quality.

Modern grinding systems incorporate real-time monitoring of critical parameters including temperature, pressure, motor load, and classifier speed. This data enables operators to maintain optimal grinding conditions and quickly identify any deviations that could affect product quality.

After grinding, barite powders require careful handling to maintain their quality. This includes efficient collection systems, proper packaging to prevent moisture absorption, and controlled storage conditions to preserve the material’s properties until incorporation into rubber compounds.

A major rubber manufacturer implemented SCM Ultrafine Mill technology for their barite grinding operations, resulting in significant improvements in their final products:

The company used conventionally ground barite (D97 ≈ 45μm) in their anti-vibration mounts, experiencing inconsistent performance, particularly in dynamic applications. Product rejection rates averaged 8% due to surface defects and dimensional instability.

Switching to superfine barite (D97 = 8μm) produced by the SCM800 mill resulted in:

While superfine grinding technology represents a significant investment, the economic benefits for rubber compounders are substantial:

Superfine barite typically provides enhanced reinforcement, allowing for reduced loading levels while maintaining or improving performance characteristics. This can lead to significant material cost savings, particularly in compound formulations with high filler content.

The better dispersion and flow characteristics of superfine barite reduce mixing times and energy consumption during compound preparation. Additionally, improved extrusion characteristics can increase production rates and reduce scrap.

Rubber products incorporating superfine barite typically command premium prices due to their superior performance characteristics, creating opportunities for market differentiation and increased profitability.

The intersection of barite processing technology and rubber compounding continues to evolve, with several emerging trends shaping future developments:

Integration of IoT technology and artificial intelligence enables predictive maintenance, real-time optimization of grinding parameters, and automated quality control, further enhancing consistency and efficiency.

Increasing focus on environmental sustainability drives development of grinding systems with reduced energy consumption, minimal waste generation, and improved working conditions through advanced dust collection and noise reduction technologies.

Research continues into surface-modified barite particles that provide additional functionality beyond reinforcement, such as flame retardancy, thermal conductivity modification, or self-healing capabilities in rubber compounds.

The selection of appropriate grinding technology is critical for maximizing the performance of barite in rubber compounding applications. The SCM Ultrafine Mill, with its precise particle size control, energy efficiency, and contamination-free operation, represents the optimal solution for manufacturers seeking to enhance their product quality and competitive position. As rubber technology continues to advance, the importance of superfine, consistent barite powders will only increase, making investment in advanced grinding technology an essential strategic decision for forward-thinking compounders.

For operations with different requirements, the MTW Series Trapezium Mill offers a compelling alternative, providing excellent performance for applications where the ultimate fineness is not required. Both technologies incorporate the latest advancements in grinding science, ensuring rubber manufacturers have access to the barite quality needed to meet evolving market demands.