December 06, 2025

Introduction

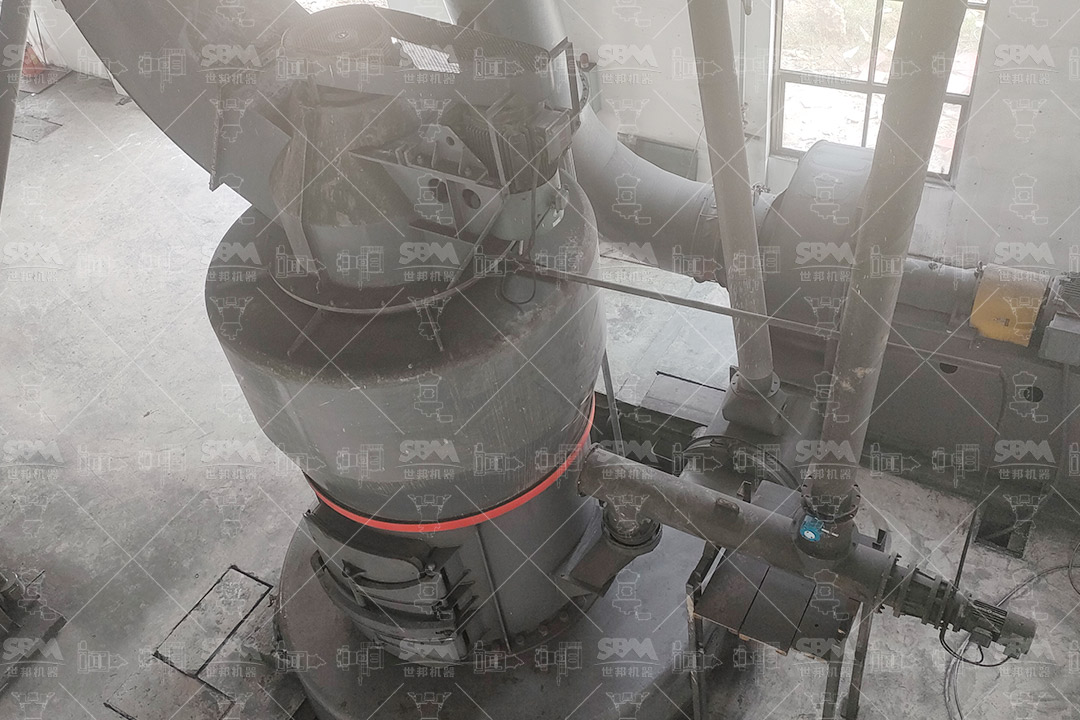

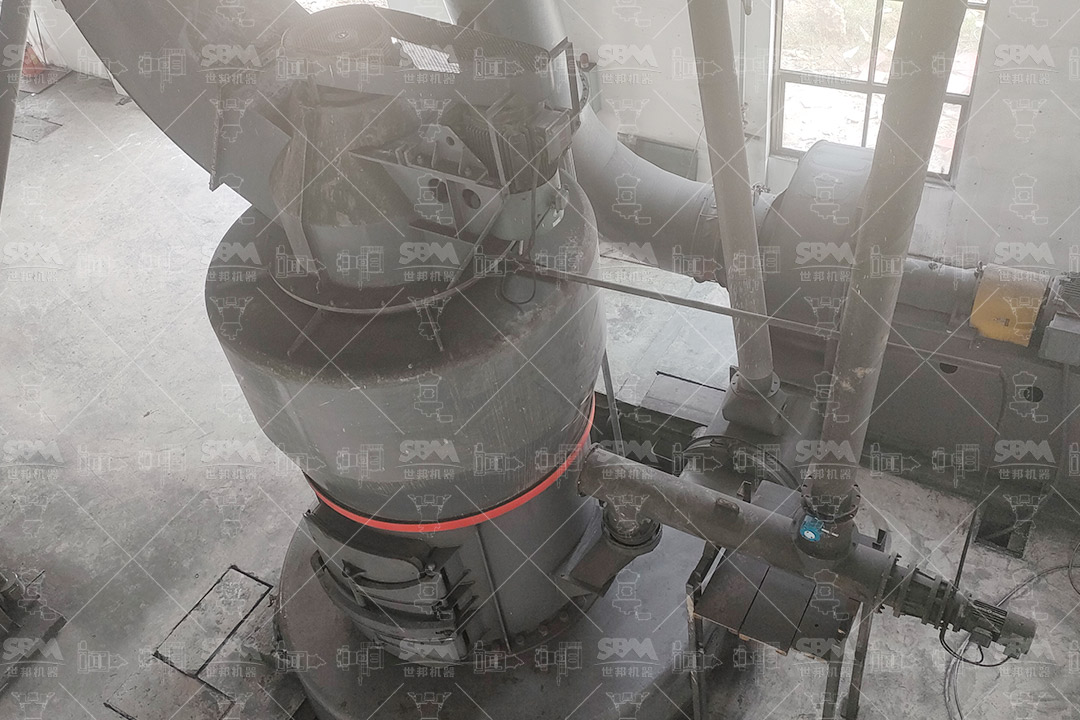

Grinding operations are fundamental across numerous industries, from mining and construction to pharmaceuticals and food processing. While essential for material size reduction and refinement, these processes inherently involve significant hazards, including exposure to dust, noise, high-energy machinery, and moving parts. Implementing and adhering to stringent safety practices is not merely a regulatory obligation but a critical component of operational excellence, protecting personnel, ensuring equipment longevity, and maintaining productivity. This comprehensive guide outlines the best practices for safety in grinding operations, covering risk assessment, personal protective equipment (PPE), equipment-specific protocols, and environmental controls. A key aspect of operational safety is selecting the right equipment designed with safety and efficiency in mind, such as our SCM Ultrafine Mill and MTW Series Trapezium Mill, which integrate advanced safety and environmental features.

1. Fundamental Safety Principles and Risk Assessment

Before any grinding operation commences, a thorough risk assessment is mandatory. This proactive approach identifies potential hazards associated with the specific material, equipment, and process.

1.1. Hazard Identification

- Mechanical Hazards: Entanglement, crushing, shearing, and impact from rotating parts like grinding rolls, classifiers, and drive systems.

- Dust Hazards: Inhalation of fine particulate matter, which can cause respiratory illnesses (e.g., silicosis) and pose explosion risks for combustible dusts.

- Noise Hazards: Prolonged exposure to high decibel levels from motors, grinding mechanisms, and material impact can lead to hearing loss.

- Electrical Hazards: Risks from high-voltage components, control panels, and motor drives.

- Ergonomic Hazards: Manual handling of materials, bags, or components leading to musculoskeletal injuries.

1.2. Implementing Controls (Hierarchy of Controls)

Following the hierarchy of controls ensures the most effective mitigation strategies are employed:

- Elimination: Redesign the process to remove the hazard (e.g., using pre-crushed material to reduce initial size).

- Substitution: Replace a hazardous material or process with a less hazardous one.

- Engineering Controls: Isolate people from the hazard. This is where modern grinding equipment excels. Features like fully sealed negative-pressure systems, integrated high-efficiency pulse-jet bag dust collectors, and soundproof enclosures are prime examples.

- Administrative Controls: Change the way people work through procedures, training, and signage (e.g., lockout/tagout – LOTO).

- Personal Protective Equipment (PPE): Used as a last line of defense when other controls cannot fully eliminate the risk.

2. Personal Protective Equipment (PPE) for Grinding Operations

PPE is essential for protecting workers from residual risks. Mandatory PPE for grinding areas typically includes:

| PPE Item |

Purpose |

Specifications/Notes |

| Respiratory Protection |

Protect against fine dust inhalation. |

NIOSH-approved respirators (N95/P100) or powered air-purifying respirators (PAPRs) for high-dust environments. |

| Hearing Protection |

Prevent noise-induced hearing loss. |

Earplugs or earmuffs with a suitable Noise Reduction Rating (NRR). Equipment like our SCM Mill, with noise levels ≤75dB, significantly reduces this burden. |

| Eye & Face Protection |

Shield from flying particles, dust, and potential splashes. |

Safety goggles or full-face shields. Anti-fog coatings are recommended. |

| Protective Clothing |

Prevent skin contact with dust and abrasion. |

Coveralls made of durable material. Anti-static clothing may be required in explosive atmospheres. |

| Safety Footwear |

Protect feet from heavy falling objects and provide slip resistance. |

Steel-toe boots with puncture-resistant soles. |

| Industrial Gloves |

Protect hands during material handling and maintenance. |

Material appropriate for the task (e.g., cut-resistant, chemical-resistant). |

3. Equipment-Specific Safety Protocols

3.1. Pre-Operation Checks

- Inspection: Visually inspect the mill, classifiers, ducts, and dust collection system for wear, damage, or blockages. Check lubrication levels.

- Guarding: Ensure all moving parts (belts, pulleys, shafts) are properly guarded. Never operate with guards removed.

- Clearance: Verify the area around the equipment is clear of personnel, tools, and obstacles.

3.2. Safe Operation Procedures

- Start-up Sequence: Always follow the manufacturer’s recommended start-up sequence, typically starting the dust collector and air system before the main grinder.

- Feed Control: Feed material at a consistent and recommended rate. Overfeeding can cause blockages, motor overload, and equipment damage. Our MTW Series Trapezium Mill features optimized curved air ducts and an efficient drive system that handles feed variations more stably, reducing the risk of overload-related incidents.

- Monitoring: Continuously monitor amperage, temperature, pressure, and noise levels. Abnormal readings should trigger an immediate shutdown for investigation.

3.3. Maintenance and Lockout/Tagout (LOTO)

Maintenance is a high-risk activity. A strict LOTO procedure is non-negotiable.

- Notify all affected personnel.

- Shut down the equipment using normal procedures.

- Isolate all energy sources (electrical, pneumatic, gravitational).

- Apply lockout devices and tags to each energy isolation point.

- Verify zero energy state by attempting to start the equipment from the local controls (after ensuring no one is in danger).

- Perform maintenance. For equipment like our SCM Ultrafine Mill, its durable design with special material rollers and rings extends service intervals, while features like the bearing-less screw grinding chamber simplify and reduce the frequency of high-risk internal maintenance.

- Remove tools, re-install guards, ensure the work area is clear, remove lockout devices, and notify personnel before re-energizing.

4. Dust Control and Explosion Prevention

Dust is the most pervasive hazard in grinding. Effective control is a multi-layered engineering challenge.

4.1. Containment and Collection

- Sealed Systems: Modern mills operate under negative pressure, preventing dust escape. Our SCM Ultrafine Mill, for example, features a fully sealed grinding chamber coupled with a pulse-jet dust collector that exceeds international standards for filtration efficiency (>99.9%).

- High-Efficiency Dust Collectors: Pulse-jet bag filters or cartridge collectors are essential. Regular inspection and replacement of filter media are critical.

- Dust Extraction Points: Ensure hoods and pick-up points are correctly placed at material transfer points, screens, and classifier outlets.

4.2. Explosion Protection (For Combustible Dusts)

- Explosion Risk Assessment: Determine the explosibility (Kst, Pmax) of the dust.

- Explosion Venting: Install properly sized explosion vents on equipment and dust collectors to safely direct pressure and flames outdoors.

- Explosion Isolation: Use chemical or mechanical isolation valves to prevent explosion propagation through ducts.

- Inerting: Use nitrogen or other inert gases to reduce oxygen levels in the grinding system below the Minimum Oxygen Concentration (MOC).

5. Noise Control and Vibration Management

Long-term exposure to noise is debilitating. Engineering controls are preferred over PPE.

- Source Control: Selecting inherently quieter equipment is the first step. The SCM Ultrafine Mill incorporates an integrated soundproof room design, achieving operational noise levels of ≤75dB(A), well below the common action level in many jurisdictions.

- Enclosure: Enclosing the entire mill or its noisiest components (motors, gearboxes) with acoustic panels.

- Vibration Damping: Proper installation on vibration-damping pads or foundations prevents resonance and reduces structure-borne noise. Mills like the MTM series feature specialized damping spring bases for this purpose.

- Regular Maintenance: Worn bearings, misaligned couplings, and loose parts significantly increase noise and indicate impending failure.

6. Training and Safety Culture

Technology alone cannot guarantee safety. A robust safety culture sustained by continuous training is vital.

- Comprehensive Training: All operators and maintenance personnel must be trained on specific equipment hazards, operating procedures, emergency shutdowns, LOTO, and PPE use.

- Emergency Procedures: Regularly drill responses to fires, dust explosions, equipment malfunctions, and medical emergencies.

- Reporting Culture: Encourage reporting of near-misses, hazards, and unsafe conditions without fear of blame.

- Management Commitment: Safety must be visibly prioritized and resourced by management, from investing in safe equipment to participating in safety walks.

Conclusion

Safety in grinding operations is a systematic endeavor that integrates thoughtful risk assessment, engineering controls, procedural rigor, and a pervasive safety culture. Investing in advanced grinding technology is a powerful engineering control that addresses multiple hazards at their source. Equipment such as our SCM Series Ultrafine Mill, with its high-efficiency pulse除尘, ≤75dB noise rating, and stable, durable design, and the MTW Series Trapezium Mill, with its robust construction, efficient drive, and optimized air flow, are engineered not only for performance but also for creating a safer, cleaner, and more compliant working environment. By adhering to the best practices outlined in this guide and leveraging modern, safety-conscious equipment, operations can achieve their productivity goals while unequivocally protecting their most valuable asset: their people.