The tire manufacturing industry relies heavily on the quality of its raw materials, with carbon black being one of the most critical components. As a reinforcing filler, carbon black significantly enhances the durability, abrasion resistance, and overall performance of tires. The processing of carbon black into ultra-fine powders is paramount to achieving these superior material properties. This article explores the importance of ultrafine grinding in tire production and highlights advanced milling solutions that meet the stringent requirements of modern tire manufacturers.

Carbon black serves as a crucial reinforcement agent in tire compounds, contributing to:

The effectiveness of carbon black reinforcement depends directly on particle size distribution, surface area, and structure. Ultrafine grinding achieves the optimal particle characteristics necessary for high-performance tire applications.

Processing carbon black for tire production demands specific technical capabilities from grinding equipment:

| Parameter | Requirement | Importance |

|---|---|---|

| Particle Size | D97 ≤ 5μm (2500 mesh) | Reinforcement efficiency |

| Size Distribution | Narrow distribution curve | Consistent compound properties |

| Surface Area | High specific surface area | Improved filler-rubber interaction |

| Contamination | Minimal iron contamination | Prevention of rubber degradation |

| Processing Temperature | Controlled low temperature | Preservation of carbon structure |

For high-performance tire production, we recommend our SCM Series Ultrafine Mill specifically designed for carbon black processing. This mill achieves exceptional fineness ranging from 325-2500 mesh (D97 ≤ 5μm) with processing capacities from 0.5-25 tons per hour depending on the model.

The SCM Ultrafine Mill offers several distinct advantages for carbon black processing:

| Model | Processing Capacity (t/h) | Main Motor Power (kW) | Feed Size (mm) | Final Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | ≤20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | ≤20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | ≤20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | ≤20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | ≤20 | 325-2500 |

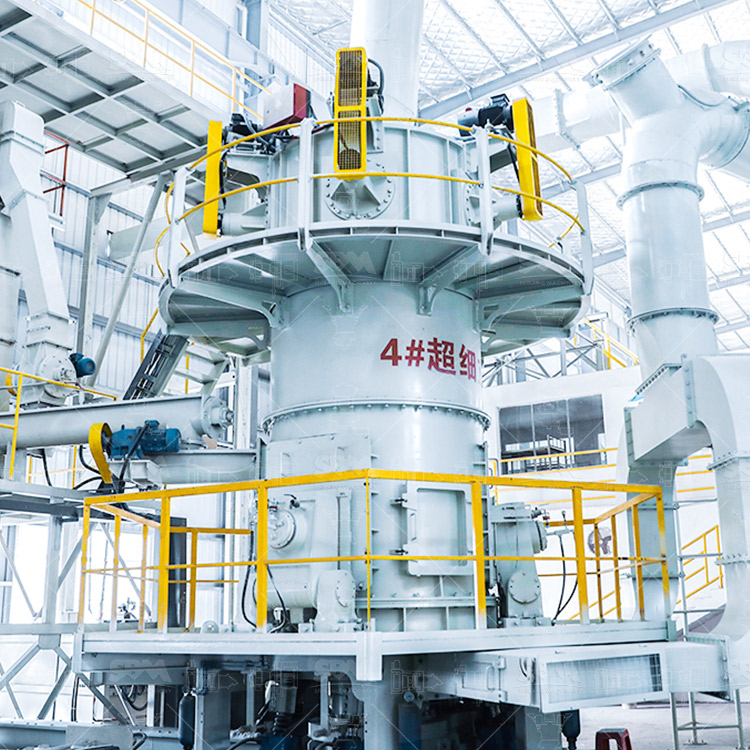

For operations requiring even higher precision or different capacity ranges, our LUM Ultra-Fine Vertical Mill provides an excellent alternative. This advanced mill system offers superior grinding efficiency with its unique roller and liner curve design, achieving fineness between 325-2500 mesh with exceptional particle size distribution control.

Integrating ultrafine grinding systems into tire production requires careful consideration of several factors:

Carbon black’s low bulk density and tendency to generate dust necessitate specialized handling systems. Our grinding mills incorporate advanced feeding mechanisms that ensure consistent material flow without segregation or compaction issues.

Modern tire production demands rigorous quality control. Our milling systems include integrated particle size monitoring and feedback systems that automatically adjust operational parameters to maintain consistent product quality.

Carbon black processing presents unique environmental challenges. Our equipment addresses these through:

Investing in advanced grinding technology provides significant economic benefits for tire manufacturers:

The high efficiency of modern ultrafine mills translates to substantial energy savings. Our SCM series demonstrates 30% lower energy consumption compared to conventional systems, with reduced maintenance requirements due to durable construction and intelligent wear compensation systems.

Superior carbon black dispersion achieved through precise grinding directly improves tire performance characteristics, enabling manufacturers to develop premium products with enhanced market competitiveness.

Typical payback periods for advanced grinding systems range from 12-24 months, considering energy savings, reduced maintenance costs, and improved product quality enabling higher market pricing.

The tire industry continues to evolve with increasing demands for sustainability and performance. Future developments in carbon black grinding include:

The production of high-performance tires demands exceptional precision in carbon black processing. Advanced ultrafine grinding technology, particularly our SCM Series Ultrafine Mill and LUM Vertical Mill, provides tire manufacturers with the capability to achieve the precise particle characteristics necessary for superior tire performance. By investing in these advanced grinding solutions, manufacturers can enhance product quality, reduce operational costs, and maintain competitiveness in an increasingly demanding market.

As the tire industry continues to evolve toward higher performance and sustainability standards, the role of precision grinding technology will only become more critical. Our commitment to innovation in grinding technology ensures that we will continue to provide the advanced solutions necessary for tomorrow’s tire manufacturing challenges.