Gypsum, a key component in cement production and additive manufacturing (3D printing), requires precise grinding to achieve desired fineness and reactivity. The efficiency of gypsum processing directly impacts product quality, energy consumption, and environmental compliance. This article explores the critical role of advanced grinding mills in gypsum processing, focusing on cement production and additive manufacturing applications, and highlights our company’s innovative solutions.

Gypsum (CaSO₄·2H₂O) is widely used as a set retarder in cement and as a binder in additive manufacturing. Proper grinding ensures optimal particle size distribution, which enhances hydration kinetics in cement and improves layer adhesion in 3D printing. Key requirements include:

Advanced grinding technologies are essential to meet these demands while minimizing energy use and operational costs.

Various mills are employed for gypsum grinding, each with unique advantages:

Traditional ball mills are robust but energy-intensive, with limited fineness control (typically ≥74μm). They are suitable for coarse grinding but less ideal for high-precision applications.

Raymond mills offer better fineness (30-325 mesh) and are cost-effective for medium-scale production. However, they struggle with ultra-fine grinding and have higher wear rates.

VRMs provide efficient grinding with integrated drying, making them ideal for gypsum with moisture content. They offer fineness up to 325 mesh and lower energy consumption compared to ball mills.

For additive manufacturing, ultrafine mills (e.g., producing 5-45μm) are critical. They ensure precise particle size distribution and high purity, essential for 3D printing materials.

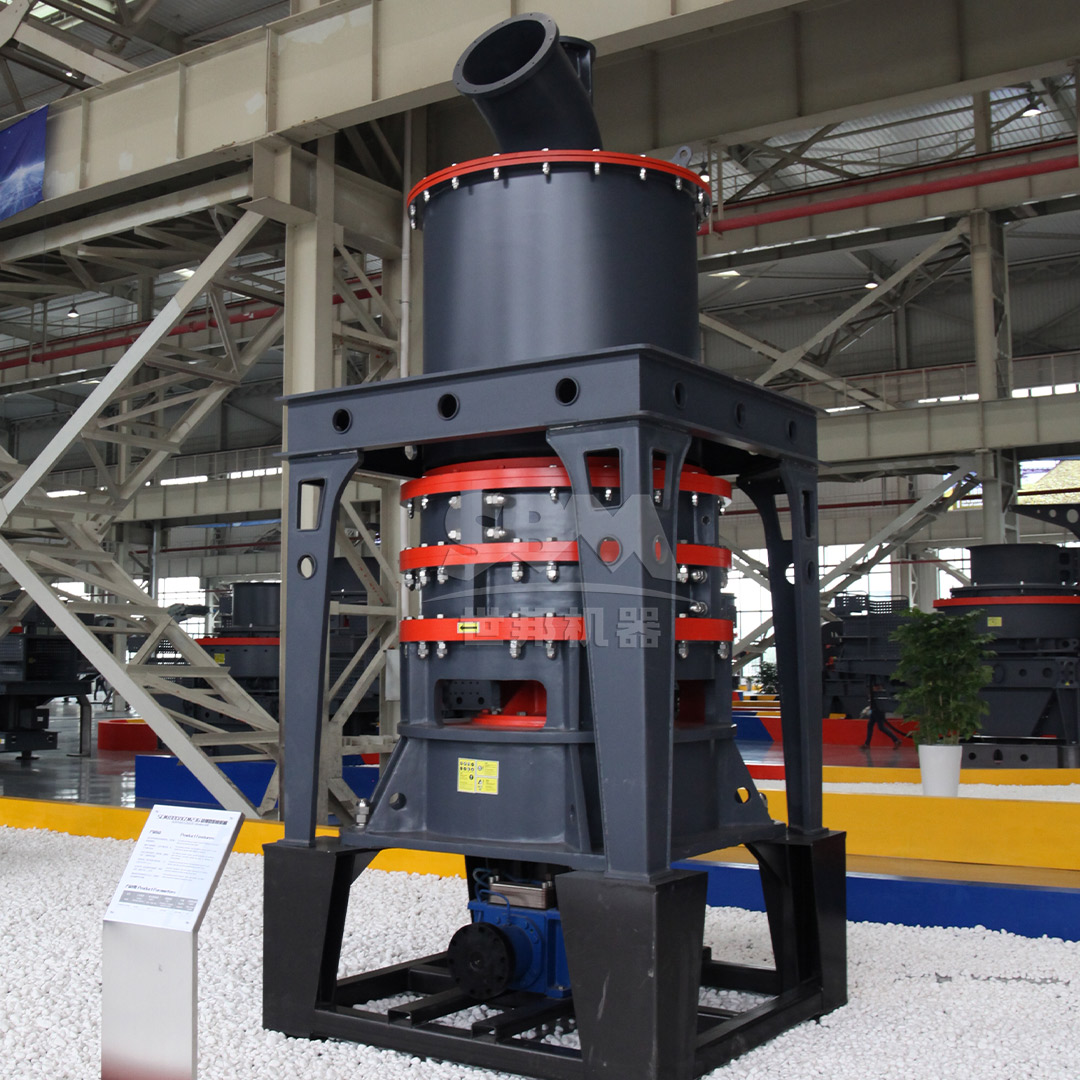

For high-precision gypsum grinding, we recommend our SCM Ultrafine Mill, designed to achieve fineness up to 2500 mesh (D97 ≤5μm). This mill is ideal for both cement production and additive manufacturing, offering:

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Output Fineness (mesh) |

|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 325-2500 |

The SCM mill operates via a multi-layer grinding ring system driven by a central motor. Material is centrifugally dispersed into the grinding path, crushed by rollers, and collected by a cyclone and pulse dust removal system.

For larger-scale cement production with fineness requirements of 30-325 mesh, our MTW Series Trapezium Mill is an excellent choice. It features:

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Output Fineness (mesh) |

|---|---|---|---|

| MTW110 | 3-9 | 55 | 30-325 |

| MTW138Z | 6-17 | 90 | 30-325 |

| MTW175G | 9.5-25 | 160 | 30-325 |

| MTW215G | 15-45 | 280 | 30-325 |

The MTW mill utilizes a rotating grinding roller and ring system with centrifugal force to crush materials, accompanied by an efficient classifying system.

In cement plants, gypsum grinding ensures optimal setting time and strength development. The SCM Ultrafine Mill provides:

Case studies show a 20% increase in grinding efficiency and 15% reduction in energy costs when using SCM mills compared to traditional systems.

For 3D printing, gypsum powder must meet stringent criteria:

The SCM Ultrafine Mill excels here, producing powder with D97 ≤5μm and excellent sphericity. Its closed-loop system prevents contamination, making it ideal for high-value additive manufacturing materials.

Our grinding solutions emphasize sustainability:

Overall, these mills offer a rapid return on investment, typically within 1-2 years, through lower operational costs and higher product quality.

Gypsum grinding is a critical process in cement and additive manufacturing industries. Advanced mills like the SCM Ultrafine Mill and MTW Trapezium Mill provide the precision, efficiency, and reliability needed for modern production. Our company is committed to delivering cutting-edge grinding technology that enhances productivity while supporting environmental goals. For more information, contact our technical team to explore the best solution for your needs.