The production of high-quality nutritional supplements demands precise control over raw material processing, particularly when it comes to calcite grinding. Calcite, a naturally occurring form of calcium carbonate, is a fundamental ingredient in many calcium supplements. Its bioavailability and efficacy are heavily influenced by particle size distribution and purity. Selecting the appropriate grinding mill is not merely an equipment choice; it is a critical decision that impacts product quality, production efficiency, operational costs, and regulatory compliance. This comprehensive guide will navigate you through the essential factors and technological considerations for choosing the ideal calcite grinding mill for your supplement production line.

Calcite (CaCO₃) is prized in the supplement industry for its high calcium content and relatively low cost. However, to be effective in the human body, it must be processed into a fine, consistent powder. The key parameters for supplement-grade calcite include:

The single most important factor is the target particle size. Different mills have inherent limitations on their fineness range.

Your production volume dictates the size and model of the mill. It’s crucial to match the mill’s capacity with your current and projected future needs to avoid bottlenecks or underutilized capital.

Nutritional supplements are subject to strict FDA and international health regulations. The mill must be constructed with materials that prevent the ground calcite from being contaminated with heavy metals from wearing parts. Ceramic-lined mills or those with special alloy grinding elements are often specified.

Grinding is an energy-intensive process. A more energy-efficient mill can significantly reduce long-term operational expenses. Look for mills with advanced drive systems and optimized grinding mechanics.

Consider the entire system, including feeding, grinding, classifying, and collecting. An integrated system with a small footprint can save valuable floor space in your production facility.

Mills should operate with minimal noise pollution and must be equipped with high-efficiency pulse-jet baghouse dust collectors to protect workers and ensure a clean production environment.

| Mill Type | Typical Output Range | Key Advantages | Potential Drawbacks for Supplements | Best Suited For |

|---|---|---|---|---|

| Ball Mill | 0.074-0.8mm (200-20 mesh) | High capacity, simple operation | Limited fineness, higher risk of contamination, high energy consumption | Preliminary, coarse grinding stages |

| Raymond Mill (MTW/MTM) | 45-325 mesh | Stable operation, wide application | Struggles to achieve ultrafine levels, moderate wear | Standard fine grinding for general supplements |

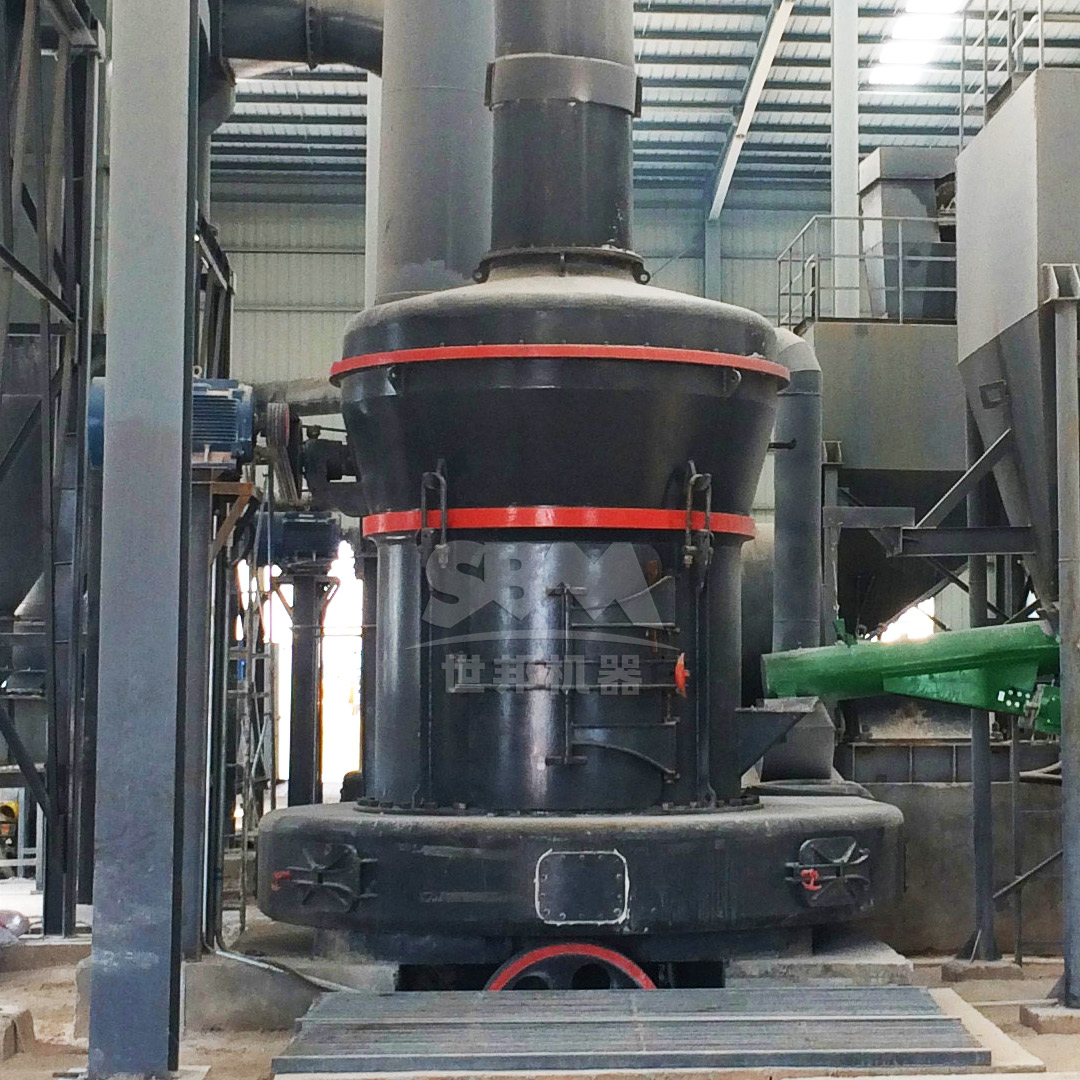

| Vertical Roller Mill (LM Series) | 30-600 mesh | High energy efficiency, integrated drying/grinding, low noise | Higher initial investment, more complex maintenance | Large-scale production of fine calcite powder |

| Ultrafine Mill (SCM/LUM) | 325-2500 mesh | Exceptional fineness, high classification accuracy, low contamination | Lower single-machine capacity compared to larger vertical mills | High-end, high-bioavailability supplement production |

For producers aiming for the premium segment of the market, where ultrafine particle size and supreme purity are non-negotiable, the SCM Ultrafine Mill stands out as an exemplary choice.

This mill is engineered specifically for producing powders in the 325 to 2500 mesh (5-45μm) range, making it ideal for creating highly bioavailable calcite for supplements. Its technological advantages directly address the critical needs of supplement production:

With models like the SCM800 (0.5-4.5 t/h) to the SCM1680 (5-25 t/h), it offers a scalable solution for growing supplement businesses.

For supplement manufacturers with large-volume production requirements for fine calcite powder (30-325 mesh), the MTW Series Trapezium Mill presents a robust and efficient solution. Its advanced features, such as the curved air duct for reduced energy loss and the overall conical gear transmission with 98% efficiency, make it a workhorse for consistent, high-tonnage output. The modular wear-resistant shovel design also simplifies maintenance and reduces downtime, which is crucial for continuous production lines. Models like the MTW215G can handle up to 45 tons per hour, making it perfect for large-scale supplement producers.

Selecting the right calcite grinding mill is a strategic investment in the quality and success of your nutritional supplement products. While several mill types can process calcite, the specific demands of the supplement industry—ultra-fineness, high purity, and strict contamination control—make advanced mills like the SCM Ultrafine Mill the preferred choice for premium applications. By carefully analyzing your production requirements against the technological capabilities of available mills, you can make an informed decision that ensures regulatory compliance, maximizes bioavailability, and optimizes your production economics for years to come.