The quality of calcite powder is paramount in ceramic production, directly influencing the final product’s strength, whiteness, and thermal properties. Achieving the required fineness and particle size distribution (PSD) necessitates the use of specialized superfine grinding equipment. Selecting the appropriate mill is not merely a question of capacity but a strategic decision impacting product quality, operational costs, and environmental compliance. This comprehensive guide will navigate the critical factors involved in choosing the ideal calcite superfine mill to meet the stringent demands of high-quality ceramic manufacturing.

Calcite (Calcium Carbonate, CaCO₃) serves as a crucial flux and filler in ceramic bodies and glazes. Its primary functions include:

The effectiveness of calcite in these roles is heavily dependent on its fineness and purity. Ultra-fine calcite powder (typically D97 ≤ 10μm, and often down to 5μm) ensures a homogeneous mixture, a smoother glaze surface, and more predictable firing behavior.

This is the most critical parameter. For high-end ceramics, a tight PSD with a top cut (D97) of 5-10 microns is standard.

The mill must have a highly efficient and precise internal classification system to ensure the target fineness is consistently met without coarse particles contaminating the product.

Match the mill’s hourly throughput (e.g., 0.5-25 t/h) with your plant’s current and future production plans. Consider:

Grinding to superfine levels is energy-intensive. Key considerations include:

The mill is part of a larger system involving feeding, grinding, classification, and collection.

Ceramic plants must adhere to strict environmental regulations.

Different mill technologies offer varying advantages for calcite processing. The following table provides a comparative overview.

| Mill Type | Typical Output Fineness (D97) | Key Advantages | Key Limitations | Suitability for High-Quality Ceramics |

|---|---|---|---|---|

| Ball Mill | 45 – 150 μm | Simple operation, wide availability | High energy consumption, poor PSD control, limited to coarse grinding | Low – unsuitable for superfine requirements |

| Raymond Mill (MTM/MTW) | 45 – 175 μm | Reliable, cost-effective for coarse to medium fineness | Limited top fineness, higher wear for hard materials | Medium – suitable for body preparation, not for glazes |

| Vertical Roller Mill (LM Series) | 45 – 100 μm | High capacity, good energy efficiency, integrated drying | Fineness may be limiting for premium applications | Good – excellent for high-volume body preparation |

| Ultrafine Mill (SCM Series) | 5 – 45 μm (325-2500 mesh) | Exceptional fineness, tight PSD, high efficiency, low noise | Higher initial investment than conventional mills | Excellent – ideal for superfine glaze and body powders |

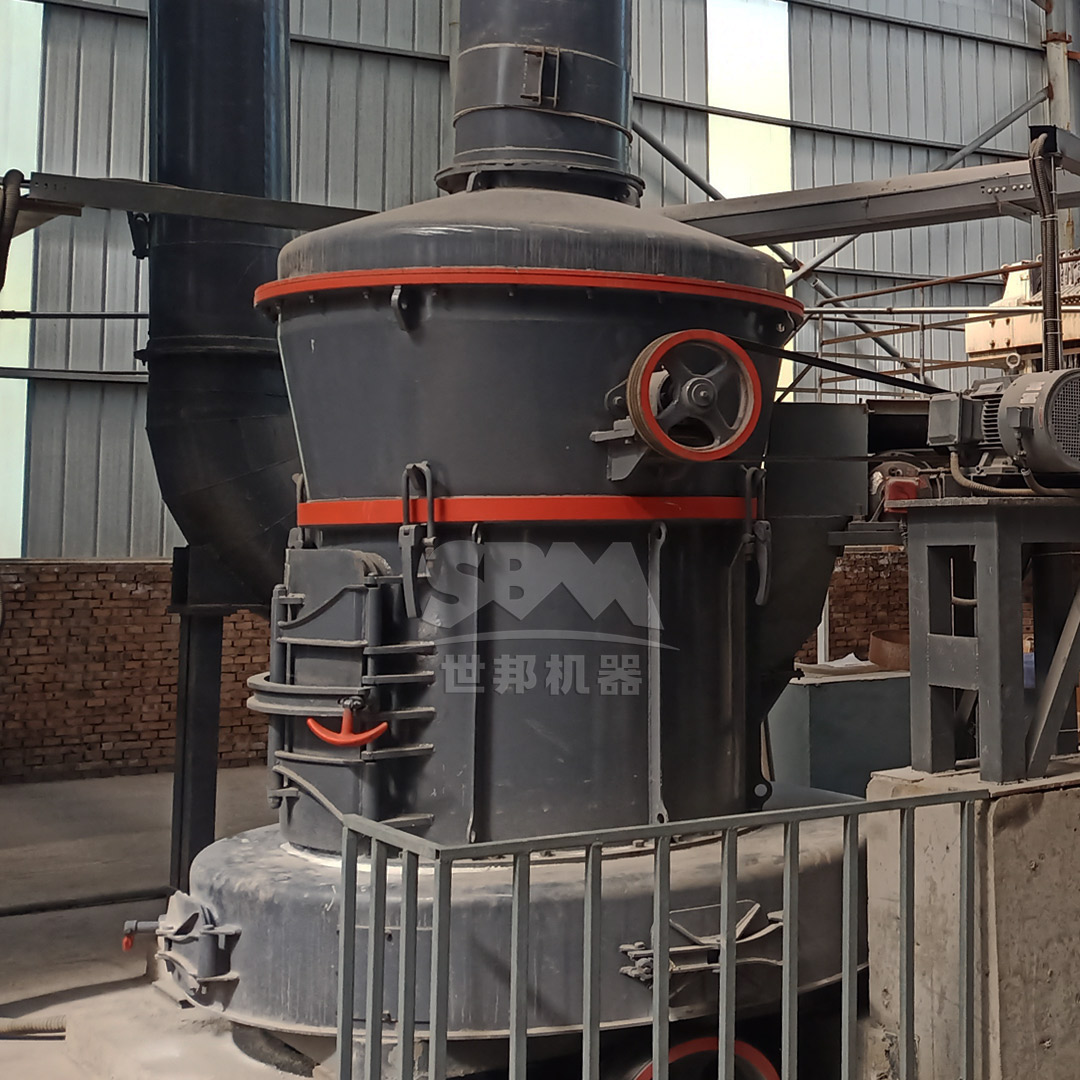

For the demanding fineness standards of high-quality ceramics, Ultrafine Mills represent the state-of-the-art technology. Unlike traditional mills that rely primarily on impact or attrition, ultrafine mills combine mechanical milling with precise air classification in a single unit. This integrated approach is key to achieving a uniform, coarse-free product.

Based on the stringent requirements for fineness, efficiency, and environmental control, the SCM Series Ultrafine Mill stands out as a premier choice for ceramic producers aiming for the highest product quality.

This mill is engineered specifically for producing powders in the 325 to 2500 mesh range (D97 ≤ 5μm), making it perfectly suited for preparing calcite for premium ceramic applications.

The SCM series offers a range of models to match different production scales. For ceramic plants, common selections include:

For producers with very high capacity needs or those processing other ceramic minerals like quartz or feldspar to similar fineness, the MTW Series Trapezium Mill is an excellent alternative for slightly coarser requirements (30-325 mesh). Its curved duct design and overall transmission system offer high efficiency and stability for large-volume processing lines.

Selecting the right calcite superfine mill is a strategic investment in the quality and competitiveness of your ceramic products. By prioritizing key factors such as final fineness, particle size distribution, energy efficiency, and environmental compliance, manufacturers can make an informed decision. For applications demanding the highest levels of fineness and purity—such as premium glazes and high-strength technical ceramics—the SCM Series Ultrafine Mill provides a technologically advanced, reliable, and economical solution. Its ability to consistently produce calcite powder down to 5μm with a narrow PSD makes it an indispensable tool for any ceramic producer aiming for excellence in the global market.