The manufacturing of construction materials relies heavily on the quality and consistency of raw material processing. Gypsum, a key component in products like drywall, plaster, and cement, requires precise pulverization to achieve the desired properties in the final product. Selecting the appropriate gypsum pulverizer is crucial for optimizing production efficiency, product quality, and operational costs. This comprehensive guide will walk you through the critical factors to consider when choosing a gypsum pulverizer and highlight some of the industry’s leading solutions.

Before selecting a pulverizer, it’s essential to understand the specific requirements of gypsum processing for construction materials. Gypsum rock must be reduced from large chunks to fine powder, with the final fineness directly impacting the performance characteristics of the construction products.

Gypsum (CaSO₄·2H₂O) has several unique characteristics that influence pulverizer selection:

| Application | Required Fineness | Special Requirements |

|---|---|---|

| Drywall Production | 100-200 mesh | Consistent particle size distribution |

| Plaster Manufacturing | 200-325 mesh | Controlled dehydration during grinding |

| Cement Additive | 200-400 mesh | High purity, minimal contamination |

| Specialty Construction Products | 400-2500 mesh | Ultra-fine particles with narrow distribution |

The fineness of the final gypsum powder is perhaps the most critical factor in pulverizer selection. Different construction applications require specific particle size distributions:

Your production volume dictates the size and type of pulverizer needed. Consider both current requirements and future expansion plans:

Energy consumption represents a significant portion of operating costs in gypsum processing. Modern pulverizers offer various energy-saving features:

The physical footprint of the pulverizer system must align with your available space. Consider:

Long-term operational expenses include:

Hammer mills are impact-based pulverizers suitable for coarse to medium grinding of gypsum. They work by using rapidly rotating hammers to collide with the material, breaking it into smaller particles.

Advantages for Gypsum Processing:

Limitations:

Ball mills are rotating cylinders filled with grinding media (balls) that cascade and impact the gypsum, gradually reducing its size through attrition and impact.

Advantages for Gypsum Processing:

Limitations:

Vertical roller mills use cylindrical rollers that press against a rotating grinding table, crushing the gypsum between them. This technology has become increasingly popular for gypsum processing due to its efficiency and flexibility.

Advantages for Gypsum Processing:

Limitations:

For applications requiring extremely fine gypsum powders, specialized ultra-fine grinding mills are necessary. These systems typically combine grinding with advanced classification to achieve precise particle size control.

Advantages for Gypsum Processing:

Limitations:

For construction material manufacturers requiring ultra-fine gypsum powder with superior quality, the SCM Ultrafine Mill represents an optimal solution. This advanced pulverizer is specifically engineered to handle the unique characteristics of gypsum while delivering exceptional performance.

Key Features for Gypsum Processing:

The SCM Ultrafine Mill operates through a sophisticated grinding mechanism where the main motor drives multiple layers of grinding rings to rotate. Gypsum material is dispersed into the grinding path by centrifugal force, undergoing sequential grinding between rollers and rings. The final powder collection is efficiently handled by a cyclone collector and pulse dust removal system, ensuring minimal product loss and environmental compliance.

Technical Advantages for Gypsum Applications:

With models ranging from the SCM800 (0.5-4.5 t/h) to the SCM1680 (5.0-25 t/h), this mill series offers scalable solutions for gypsum processors of all sizes.

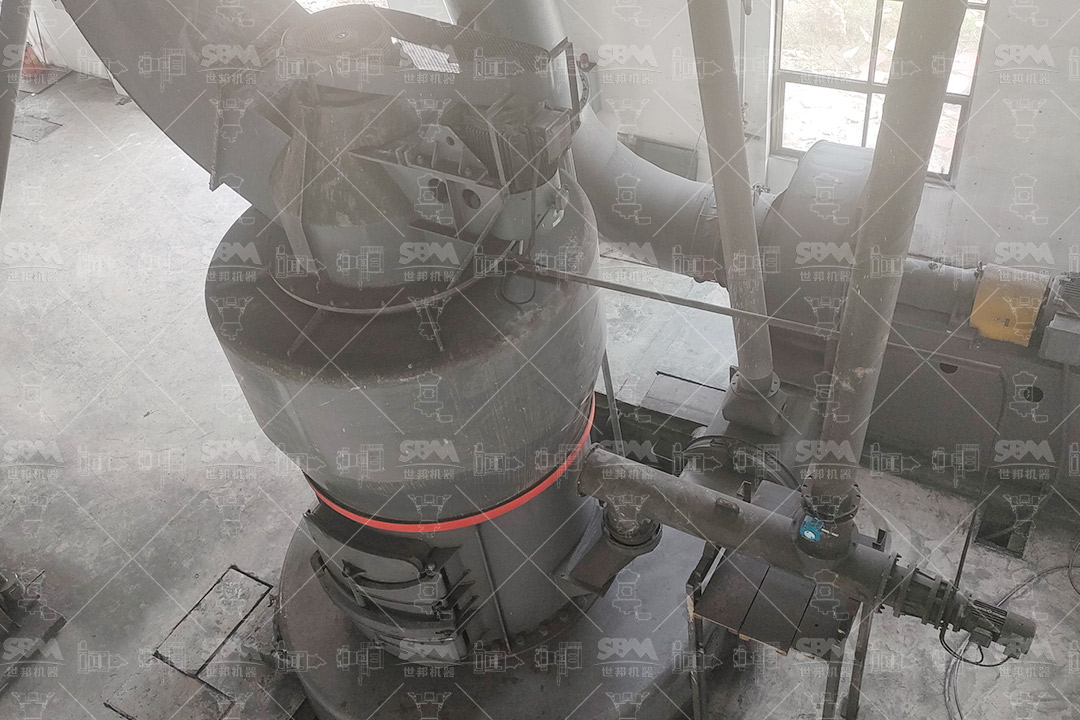

For construction material manufacturers requiring reliable, high-capacity gypsum pulverization for standard applications, the MTW Series Trapezium Mill provides an excellent balance of performance, efficiency, and cost-effectiveness.

Key Features for Gypsum Processing:

The MTW Series operates through an efficient grinding principle where the main motor drives grinding rollers to revolve around the central axis while rotating themselves. The shovel blades throw materials between the grinding ring and rollers, creating a material bed that undergoes efficient compression grinding. The integrated classification system provides precise control over final product fineness.

Technical Advantages for Gypsum Applications:

With multiple models including the MTW110 (3-9 t/h) up to the MRN218 (15-45 t/h), the MTW Series offers flexible solutions tailored to specific production requirements and space constraints.

| Pulverizer Type | Optimal Fineness Range | Capacity Range (t/h) | Energy Efficiency | Initial Investment | Best Application |

|---|---|---|---|---|---|

| Hammer Mill | 0-3mm | 8-70 | Medium | Low | Coarse grinding, initial reduction |

| Ball Mill | 0.074-0.8mm | 0.65-450 | Low-Medium | Medium | General purpose, blending |

| MTW Trapezium Mill | 30-325 mesh | 3-45 | High | Medium-High | Standard construction products |

| SCM Ultrafine Mill | 325-2500 mesh | 0.5-25 | Very High | High | High-performance specialty products |

| Vertical Roller Mill | 30-600 mesh | 3-250 | High | High | Large-scale integrated operations |

Proper installation is crucial for optimal pulverizer performance. Key considerations include:

Successful pulverizer operation requires proper training and maintenance planning:

Gypsum processing must address several environmental and safety considerations:

Selecting the right gypsum pulverizer for construction material manufacturing requires careful consideration of multiple factors, including required product fineness, production capacity, energy efficiency, and total cost of ownership. While various technologies are available, the SCM Ultrafine Mill and MTW Series Trapezium Mill represent excellent solutions for different segments of the gypsum processing market.

The SCM Ultrafine Mill stands out for applications requiring ultra-fine gypsum powders with tight particle size distributions, offering advanced classification technology and energy-efficient operation. Meanwhile, the MTW Series Trapezium Mill provides reliable, high-capacity processing for standard construction material applications with excellent operational economics.

By thoroughly evaluating your specific requirements against the capabilities of modern pulverizer technology, you can select equipment that will deliver optimal performance, product quality, and return on investment for your gypsum processing operations. The right pulverizer choice will not only meet your current production needs but also provide flexibility for future product development and market expansion.