The steel industry relies heavily on petroleum coke (petcoke) as a cost-effective carbon source and fuel in various production processes. Proper grinding of petcoke is essential for achieving optimal combustion efficiency, reducing emissions, and maintaining consistent product quality in steel manufacturing. Selecting the right grinding mill requires careful consideration of material properties, production requirements, and operational parameters.

Petroleum coke presents unique challenges in grinding due to its abrasive nature, variable hardness, and specific particle size requirements for different steel production applications. This comprehensive guide explores the critical factors in choosing the appropriate grinding equipment and highlights technological solutions that deliver optimal performance for petcoke processing in steel plants.

Petroleum coke varies significantly in properties depending on the crude oil source and coking process. Key characteristics affecting grinding include:

| Application | Required Fineness | Special Requirements |

|---|---|---|

| Blast Furnace Injection | 80-85% passing 200 mesh (74μm) | Narrow particle distribution, low moisture |

| Basic Oxygen Furnace | 70-80% passing 100 mesh (149μm) | Consistent carbon content, low volatiles |

| Electric Arc Furnace | 65-75% passing 50 mesh (297μm) | High fixed carbon, low contamination |

| Sinter Plant Fuel | 60-70% passing 30 mesh (595μm) | Good combustibility, controlled sizing |

Steel plants require grinding systems capable of handling specific throughput rates based on production scale. The grinding mill must match the plant’s petcoke consumption, which typically ranges from 5-50 tons per hour for medium to large steel facilities. When evaluating capacity, consider both current needs and future expansion plans to avoid costly equipment replacements.

Grinding operations account for a significant portion of a steel plant’s energy consumption. Modern grinding technologies can reduce specific energy consumption by 30-50% compared to conventional systems. Key efficiency factors include:

Precise particle size control is critical for petcoke used in steel production. The grinding system must produce consistent particle size distribution with minimal oversize or fines. Advanced classification systems integrated with grinding mills enable tight control over product fineness, typically achieving D97 values with variations of less than 2%.

Petcoke’s abrasive nature necessitates robust wear protection in grinding mills. Key considerations include:

Vertical roller mills have become the preferred solution for large-scale petcoke grinding in steel plants. These systems employ multiple grinding rollers that compress and shear material against a rotating grinding table. VRMs offer several advantages for petcoke applications:

Our LM Series Vertical Roller Mill represents the cutting edge in petcoke grinding technology. With capacities ranging from 3-250 tons per hour and fineness control from 30-325 mesh, this system delivers exceptional performance for steel production requirements. The integrated dynamic classifier ensures precise particle size control, while the specially designed grinding elements provide extended service life in abrasive petcoke applications.

Traditional Raymond mills with spring-loaded grinding rollers remain popular for medium-capacity petcoke grinding applications. These systems offer:

While less common for dedicated petcoke grinding, ball mills still find application in some steel plants, particularly where flexibility for multiple materials is required. Ball mills provide:

For large steel production facilities requiring high-volume petcoke grinding, we recommend our LM Series Vertical Roller Mill. This advanced grinding system incorporates multiple technological innovations specifically designed for challenging materials like petroleum coke:

| Feature | Benefit for Petroleum Coke Grinding |

|---|---|

| Integrated Dynamic Classifier | Precise control of particle size distribution for optimal combustion |

| Special Wear Protection | Extended service life in abrasive petcoke applications |

| Hot Gas Integration | Simultaneous grinding and drying of high-moisture petcoke |

| Low Vibration Design | Stable operation with reduced structural requirements |

| PLC Automation System | Consistent product quality with minimal operator intervention |

The LM Series achieves specific energy consumption of 25-35 kWh/ton for petcoke grinding to blast furnace specifications, representing a 30-40% reduction compared to traditional ball mill systems. With models ranging from LM130K to LM370N, this series provides solutions for steel plants of all sizes.

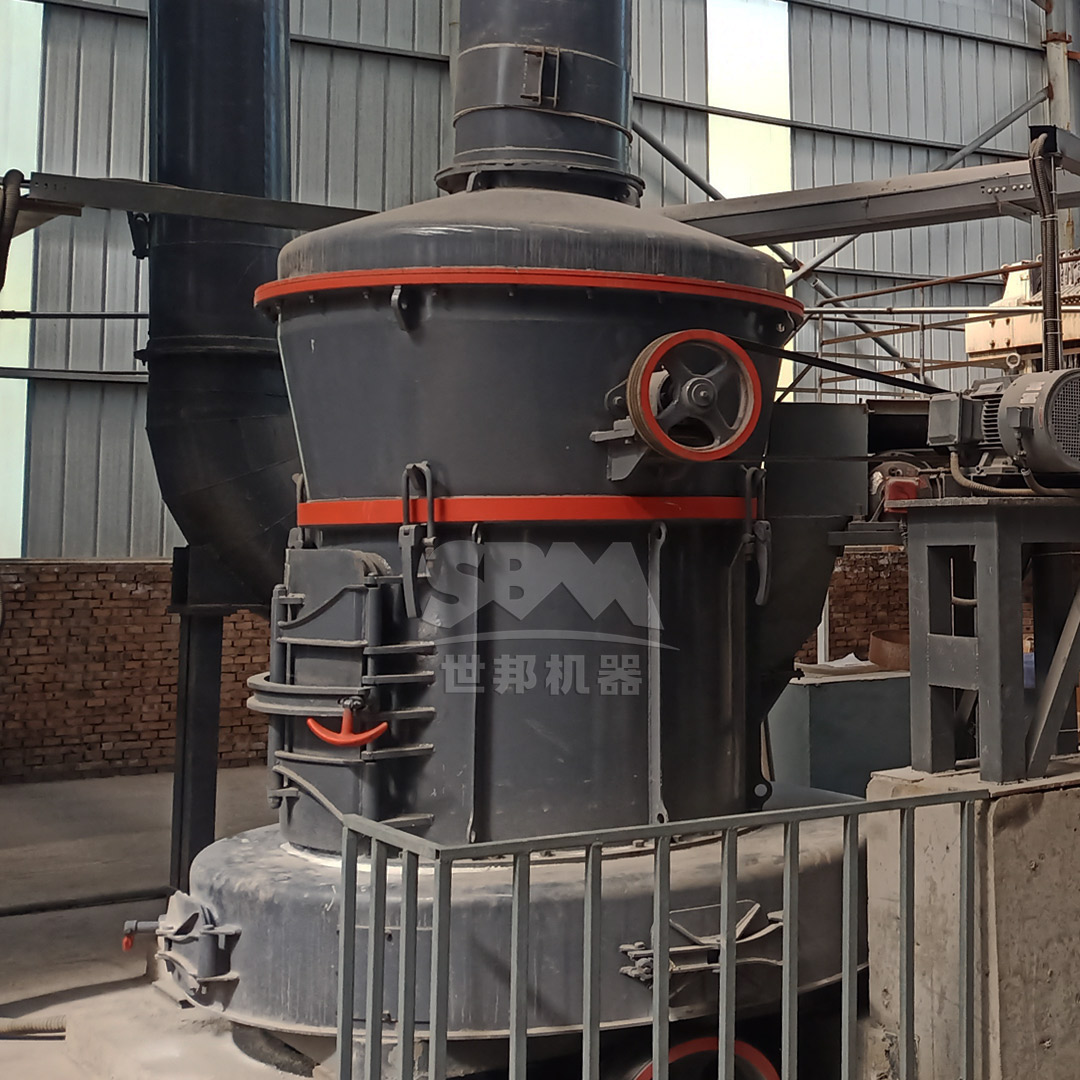

For medium-scale steel production facilities, our MTW Series Trapezium Mill offers an excellent balance of performance, reliability, and operating economy. This system features several innovations that make it particularly suitable for petcoke grinding:

The MTW Series handles feed sizes up to 50mm and produces fineness from 30-325 mesh, with capacities from 3-45 tons per hour depending on model selection. The wear-resistant grinding elements are specifically engineered for abrasive materials like petcoke, providing extended service life and reduced operating costs.

Proper feed system design is critical for optimal grinding mill performance. Key considerations for petcoke applications include:

Petroleum coke typically requires drying from initial moisture contents of 6-12% down to 1-2% for optimal grinding and combustion. Modern grinding mills integrate drying capability using hot gases, with several configuration options:

Effective dust collection is essential for petcoke grinding operations due to the material’s fine, combustible nature. Modern grinding systems incorporate comprehensive dust control measures:

Selecting the right petcoke grinding mill involves evaluating both initial capital investment and long-term operating costs. Key financial considerations include:

The total cost of ownership for petcoke grinding systems includes multiple operational factors:

| Cost Component | Typical Range | Optimization Strategies |

|---|---|---|

| Power Consumption | 25-45 kWh/ton | High-efficiency motors, optimized grinding geometry |

| Wear Parts | 0.8-1.5 USD/ton | Premium materials, proper maintenance |

| Maintenance Labor | 0.3-0.6 USD/ton | Preventive maintenance, easy access design |

| System Availability | 92-97% | Robust design, quick change components |

Modern high-efficiency grinding systems typically achieve payback periods of 18-36 months through:

A major integrated steel plant in Asia recently implemented our LM190K Vertical Roller Mill for petroleum coke grinding, achieving remarkable results:

This successful implementation demonstrates the potential benefits of selecting the appropriate grinding technology for petroleum coke in steel production applications.

Selecting the right petroleum coke grinding mill for steel production requires careful analysis of multiple factors, including production requirements, material characteristics, economic considerations, and environmental compliance. Modern grinding technologies, particularly vertical roller mills, offer significant advantages in efficiency, reliability, and operating costs compared to traditional systems.

Our LM Series Vertical Roller Mill and MTW Series Trapezium Mill provide comprehensive solutions for petroleum coke grinding across the full spectrum of steel production requirements. With advanced features specifically designed for challenging materials like petcoke, these systems deliver optimal performance while minimizing operating costs and environmental impact.

By partnering with experienced grinding technology providers and implementing best practices in system design and operation, steel producers can achieve significant improvements in production efficiency, product quality, and overall profitability through optimized petroleum coke grinding systems.