The production of high-gloss paper, a premium product used in magazines, art books, and high-end packaging, demands exceptionally smooth and reflective surfaces. This quality is primarily achieved through a sophisticated coating process where kaolin, or china clay, serves as the principal pigment. The inherent properties of kaolin—its platy structure, chemical inertness, and bright white color—make it ideal for filling the microscopic pores between paper fibers and creating a uniform, highly reflective surface. However, the raw kaolin clay must undergo a rigorous transformation: it must be dried, crushed, and most importantly, ground to a precise and exceptionally fine particle size distribution. The efficiency and capability of the grinding mill used are, therefore, paramount to the final quality of the paper coating and the overall economics of its production.

Not all kaolin powder is suitable for high-gloss applications. The coating formulation requires a product that meets strict specifications:

Transforming hard, moist kaolin lumps into a ultra-fine, consistent powder presents significant engineering challenges that not all grinding equipment can overcome.

Several types of mills are used in mineral processing, but only a few are suited for the high-end demands of coating-grade kaolin production. Traditional solutions like ball mills or Raymond mills often fall short in efficiency, fineness control, or energy consumption.

For modern high-gloss paper coating production, ultrafine grinding mills represent the technological pinnacle. These mills integrate high-intensity grinding with advanced air classification in a single, efficient system. They are specifically engineered to address the challenges of kaolin processing.

After extensive evaluation of various technologies, our SCM Ultrafine Mill series stands out as the premier solution for producing top-tier coating-grade kaolin. This mill is engineered from the ground up to deliver the precise fineness, high throughput, and operational reliability required by major paper producers.

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Input Size (mm) | Output Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | ≤20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | ≤20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | ≤20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | ≤20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | ≤20 | 325-2500 |

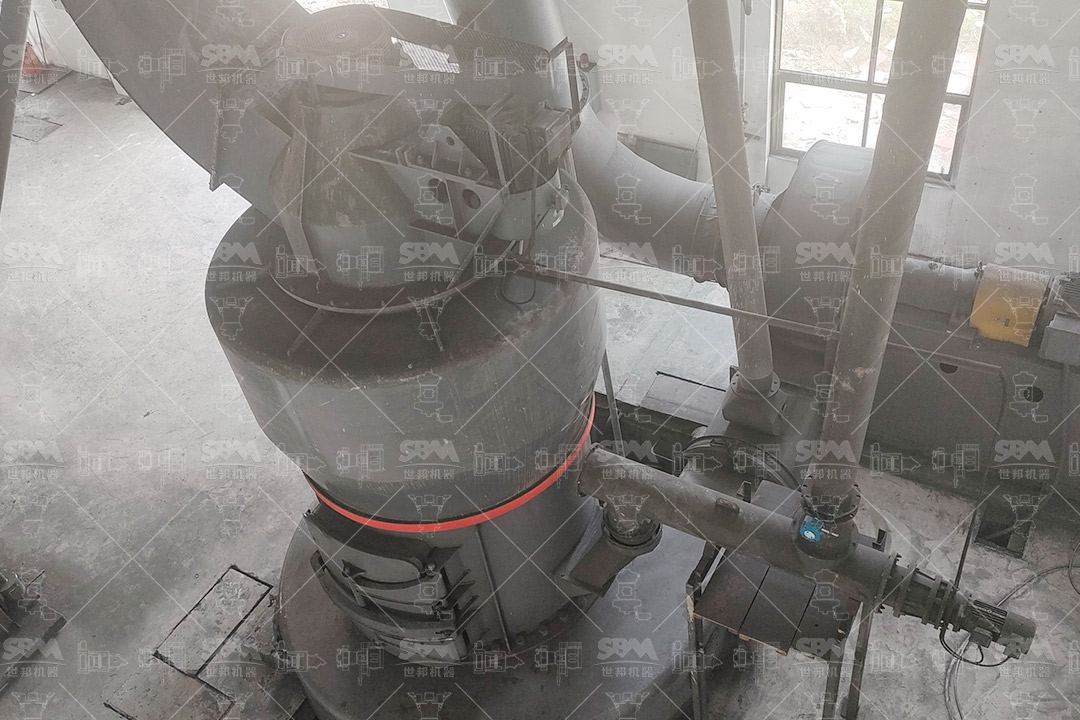

In a complete kaolin processing plant, the raw ore often requires initial size reduction before the final ultrafine grinding stage. For this crucial pre-processing step, our MTW Series Trapezium Mill is an excellent choice. Capable of handling input sizes up to 50mm and producing powders from 30-325 mesh, it efficiently prepares the material for the SCM mill. Its advantages include a wear-resistant shovel design, curved air duct for reduced energy loss, and an efficient overall gear transmission system, making it a robust and cost-effective solution for the initial grinding phases.

The pursuit of high-gloss paper quality is a precise science that begins long before the coating is applied to the paper web. It starts with the selection of high-quality kaolin and, just as importantly, the technology used to refine it. Investing in an advanced, reliable, and efficient grinding system is not merely an equipment purchase; it is a strategic decision that directly impacts product quality, production costs, and environmental compliance.

Our SCM Ultrafine Mill and MTW Series Trapezium Mill are engineered to meet the rigorous demands of the modern paper industry. By ensuring a consistent supply of perfectly sized, high-brightness kaolin powder, these mills provide the foundation for producing the exceptional high-gloss paper that the market demands. We invite you to contact our technical team to discuss how our grinding solutions can be integrated into your production process to achieve new levels of quality and efficiency.