The modern industrial mineral grinding plant is a sophisticated ecosystem engineered for efficiency, precision, and sustainability. Moving beyond simple size reduction, these plants integrate advanced comminution, classification, material handling, and dust collection technologies into a cohesive, automated system. The selection of core grinding equipment is paramount, dictating the plant’s final product quality, energy footprint, operational cost, and environmental compliance. This article explores the essential components of such a facility, with a focus on the technological advancements that define contemporary grinding solutions.

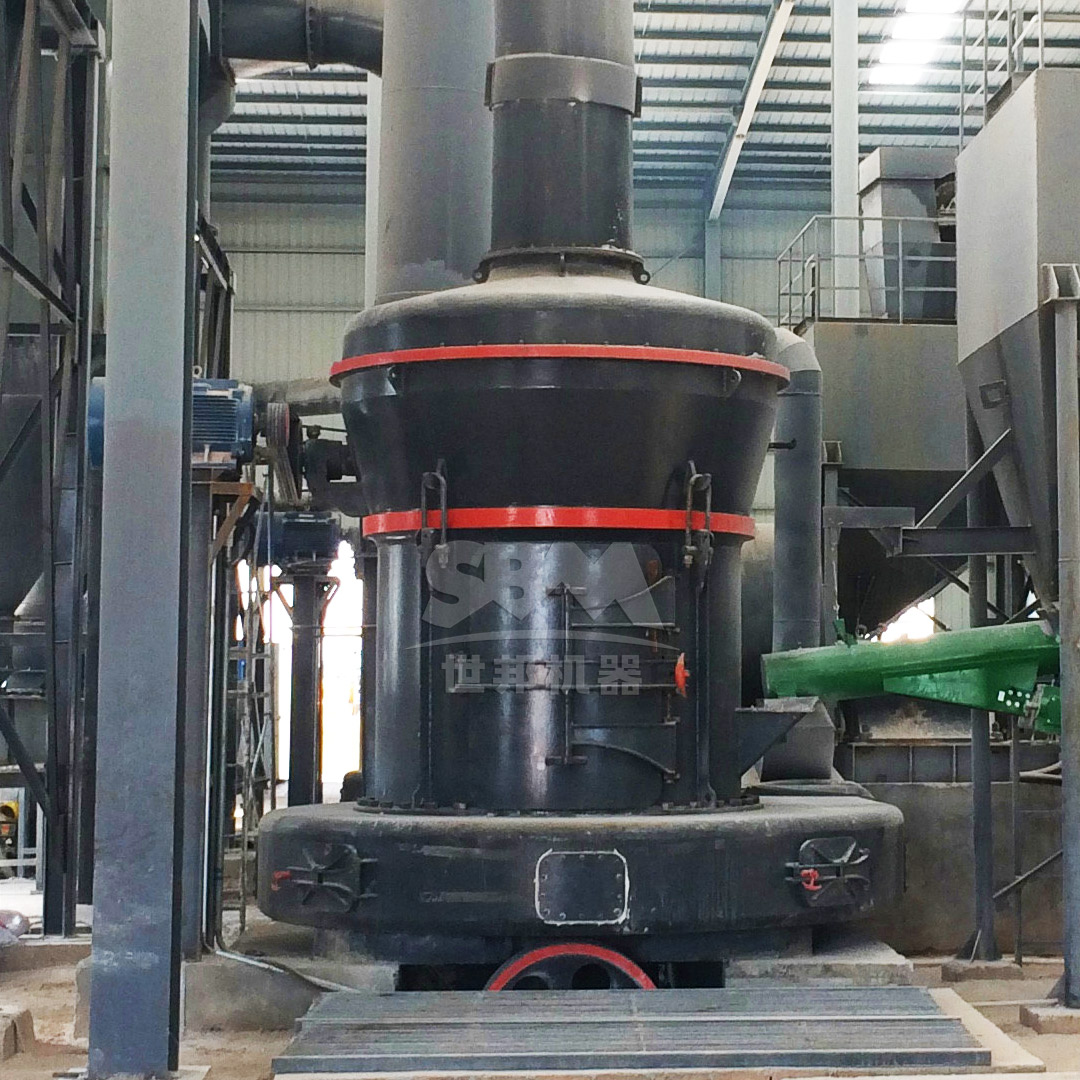

The heart of any grinding plant is its milling circuit. The choice of mill depends on the feed material’s hardness, abrasiveness, required final fineness, and desired throughput. Modern plants often employ a multi-stage approach, combining different mill types for optimal efficiency.

Before fine grinding, raw materials must be reduced to a suitable feed size. Hammer Crushers are highly effective for this stage, capable of processing materials up to 40-50mm and delivering a product as fine as 0-3mm. Their high reduction ratio, robust construction with high-manganese steel liners, and compact design make them ideal for preparing feed for downstream grinding units, minimizing the load on finer, more energy-intensive mills.

This is the most critical and energy-intensive stage. Traditional ball mills are giving way to more efficient vertical roller mills and specialized ultrafine systems.

Grinding and classification are inseparable in modern plants. Efficient separation of fine product from coarse material for re-grinding is crucial for maximizing mill throughput and preventing over-grinding.

Modern mills like the LM Series VRM and the SCM Ultrafine Mill feature integrated high-efficiency dynamic classifiers. These rotating cage separators use adjustable speed and airflow to create precise cut points, allowing for real-time adjustment of product fineness without stopping the mill. This level of control is vital for producing multiple product grades from a single line.

For the highest purity requirements or dedicated classification circuits, standalone air classifiers are used. These devices can further refine mill output, ensuring a tight particle size distribution (PSD) and removing unwanted coarse or fine fractions.

A consistent and controlled feed is critical for stable mill operation. Modern plants employ automated systems including belt conveyors, bucket elevators, and precisely metered feeding devices like weigh feeders or vibrating feeders. These systems are interlocked with the mill’s control system to maintain optimal feed rates, preventing mill overload or starvation, which directly impacts product quality and energy use.

Mineral grinding is inherently dusty. A modern plant must be a closed, negative-pressure system to protect both the environment and workers. Pulse-jet baghouse filters are the industry standard for dust collection, offering filtration efficiencies exceeding 99.9%. Advanced systems feature:

The brain of the modern grinding plant is its Distributed Control System (DCS) or Programmable Logic Controller (PLC) network. This system integrates all components, enabling:

The final ground product is typically conveyed pneumatically to large storage silos. Dense-phase pneumatic conveying is often preferred for its low velocity, minimizing product degradation and wear on pipelines. From storage, product can be packaged in bags, big bags, or loaded directly into bulk tankers via automated loading systems with integrated dust collection.

A modern mineral grinding plant is more than a sum of its parts; it is a fully integrated process where mechanical innovation, precise classification, intelligent control, and environmental stewardship converge. The selection of the core grinding technology sets the foundation for this integration. For high-capacity fine grinding of minerals like limestone, slag, or coal, the LM Series Vertical Roller Mill offers an unbeatable combination of low operating cost, high reliability, and a small physical footprint. For producers targeting the high-value ultrafine powder market, the SCM Series Ultrafine Mill provides the necessary precision, energy efficiency, and product consistency. Investing in such advanced, purpose-built technologies is key to building a grinding plant that is not only productive but also sustainable and competitive in the long term.