In modern industrial processing, the demand for fine and ultra-fine powders from mixed raw materials is growing across sectors like mining, construction, chemicals, and recycling. Designing an efficient grinding system for such heterogeneous feedstocks presents unique challenges. Unlike processing a single, uniform material, mixed materials vary in hardness, abrasiveness, moisture content, and particle size distribution. An optimal system must not only achieve the target fineness and throughput but also do so reliably, cost-effectively, and with minimal environmental impact. This article explores the key factors that engineers and plant managers must consider when designing such a system and highlights advanced technological solutions that address these complex requirements.

The foundation of any successful grinding system design is a thorough analysis of the feed material. For mixed materials, this analysis is critical and multi-faceted.

The blend may contain components with vastly different grindability indices (e.g., Bond Work Index). A mix of soft limestone and hard quartz, for instance, requires a mill that can handle the abrasive quartz without being over-engineered for the limestone. The system must be robust enough to process the hardest component while maintaining efficiency for the softer ones.

Moisture can cause agglomeration, clogging, and reduced grinding efficiency. Some materials in the mix may be dry, while others could have surface moisture. The system design must incorporate adequate drying capacity, either through pre-drying or by utilizing hot gas within the mill itself (common in vertical roller mills).

Mixed materials often come from various sources, leading to a wide range of initial particle sizes. A system must have a sufficient acceptance size and a pre-crushing or screening stage to ensure a relatively consistent feed size for the final grinding unit, optimizing its performance.

Abrasive components rapidly wear down grinding elements, increasing maintenance costs and contaminating the product. Corrosive elements can damage unprotected parts. Material selection for wear parts (rollers, liners, classifiers) is paramount.

Once material properties are understood, the engineering focus shifts to the system’s core operational parameters.

This is the most critical decision. Different technologies excel in different fineness ranges and material types.

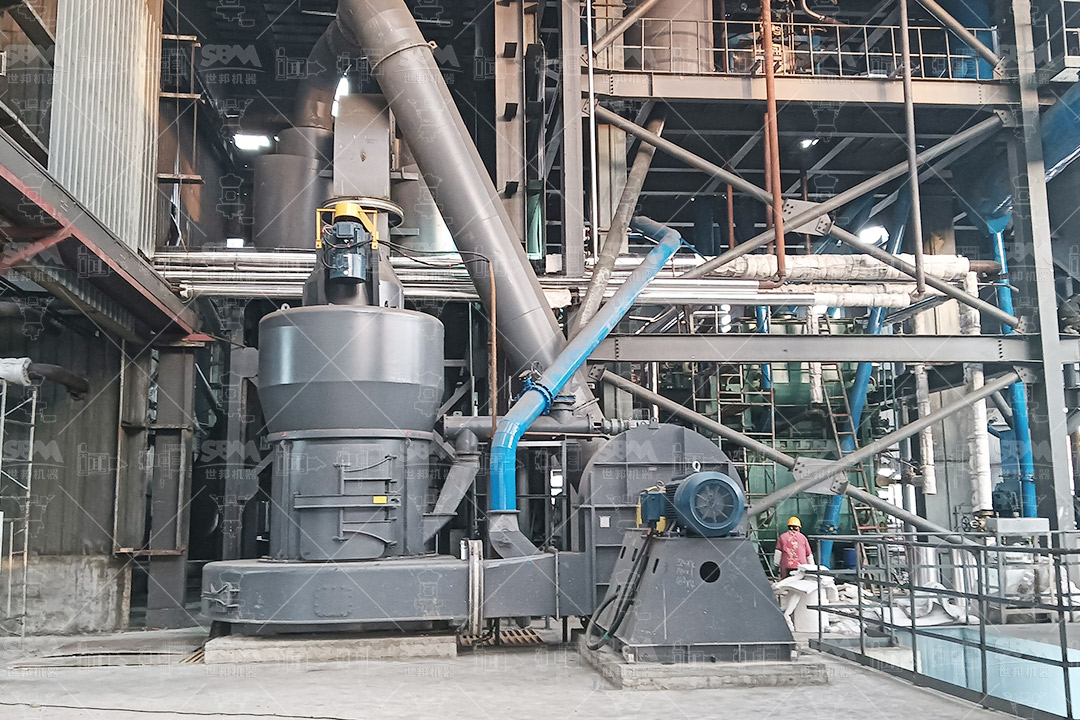

For operations targeting the fine to ultra-fine spectrum from mixed materials, our SCM Ultrafine Mill series presents an ideal solution. Engineered to handle feed sizes up to 20mm, it delivers an impressive output range of 325 to 2500 mesh (D97 ≤5μm). Its efficiency is notable, offering approximately double the capacity of jet mills while reducing energy consumption by 30%. A key advantage for processing blends is its high-precision vertical turbine classifier, which ensures accurate particle size cuts and prevents coarse powder contamination, guaranteeing a uniform final product—a vital requirement when grinding dissimilar materials.

Grinding and classification are inseparable in a modern system. An efficient internal or external classifier continuously separates fine product from coarse material, which is recirculated. For mixed materials, a classifier with adjustable speed and airflow is essential to fine-tune the cut point and compensate for variations in the feed’s grindability, ensuring a consistent product fineness (e.g., D97 value).

A grinding plant is more than just a mill. It includes feeders, conveyors, elevators, a drying circuit, a classification loop, dust collection, and product handling. These components must be seamlessly integrated. An advanced PLC-based control system is crucial for managing mixed feeds. It can adjust feed rates, grinding pressure, classifier speed, and fan airflow in real-time based on motor load and product fineness feedback, stabilizing the process despite input variability.

Grinding is inherently energy-intensive. The chosen technology should maximize the energy transferred to particle breakage. Bed-compression grinding (as in VRMs and roller mills) is generally more efficient than impact-based or tumbling ball milling. Furthermore, recovering heat from process gases and optimizing fan power for the pneumatic circuit contribute significantly to overall system efficiency.

Long-term profitability depends on reliable operation and manageable maintenance costs.

As mentioned, abrasive materials cause wear. Designing for easy access and replacement of wear parts like rollers, tires, and classifier blades minimizes downtime. Using specially hardened or composite materials can extend service life dramatically. For example, some modern mills feature rollers and rings made from advanced alloys, lasting several times longer than standard components.

Modular design philosophies, such as quick-change roller assemblies and hydraulic systems for roller positioning, are major advantages. They allow for faster, safer maintenance interventions, keeping the system online and productive.

The system must operate cleanly. This involves high-efficiency pulse-jet baghouse filters or cartridge collectors to ensure dust emissions are well below local regulations (e.g., <20 mg/Nm³). Sound enclosures or design features that reduce noise at the source are also important to meet workplace and community noise standards (<75-80 dB(A)).

For many mixed-material applications requiring high capacity in the coarse to fine range, Vertical Roller Mill technology encapsulates many of the key design factors discussed.

Our LM Series Vertical Roller Mill is a prime example of this integrated approach. Its集约化设计 (intensive design) combines crushing, grinding, drying, and classification in a single unit, reducing footprint by up to 50%. This is particularly beneficial for processing mixed feeds, as its grinding principle—where material is ground between rollers and a rotating table under pressure—is effective across a spectrum of hardness. The system’s智能控制 (intelligent control) allows for expert-level automation, enabling remote monitoring and adjustment to handle feed variations seamlessly. Furthermore, its design emphasizes低运行成本 (low operational cost) through features like non-contact grinding elements that extend wear part life and reduce specific energy consumption by 30-40% compared to ball mill systems. The全密封负压运行 (fully sealed negative pressure operation) ensures exceptional environmental performance.

| Model | Grinding Disc Diameter (mm) | Capacity Range (t/h) | Output Fineness | Main Motor Power (kW) |

|---|---|---|---|---|

| LM190K | 1900 | 23-68 | 170-40μm (80-400 mesh) | 500 |

| LM220K | 2200 | 36-105 | 170-45μm (80-325 mesh) | 800 |

| LM280K | 2800 | 50-170 | 170-45μm (80-325 mesh) | 1250 |

Designing an efficient grinding system for mixed materials is a complex optimization exercise that balances material science, mechanical engineering, and process control. Success hinges on a deep understanding of the feedstock, the strategic selection of grinding and classification technology, and a focus on total lifecycle costs—encompassing energy, maintenance, and environmental management. Technologies like the advanced Ultrafine Mills for superfine products and versatile Vertical Roller Mills for high-capacity fine grinding represent the forefront of solutions that meet these challenges. By prioritizing the key factors of material adaptability, system integration, precision control, and operational robustness, engineers can design grinding systems that are not only efficient but also resilient and sustainable for the long-term processing of complex material blends.