August 26, 2025

The Role of Ultra-Fine Marble Powder in Modern Furniture Manufacturing

The furniture industry is undergoing a significant transformation, driven by consumer demand for higher quality, more durable, and aesthetically pleasing products. At the heart of this transformation lies the use of advanced materials, particularly ultra-fine marble powder. This material, when incorporated into coatings, composites, and finishes, imparts exceptional durability, a superior smooth surface texture, and a luxurious appearance that is highly sought after in high-end furniture markets. The production of this critical material, however, is impossible without the precision and reliability of specialized grinding equipment designed to achieve consistent micron-level fineness.

Challenges in Producing Furniture-Grade Marble Powder

Producing marble powder suitable for furniture manufacturing is not a simple task of crushing stone. It requires a meticulous process that must overcome several challenges:

- Consistent Fineness: The powder must have a uniform particle size distribution. Inconsistent grit can lead to uneven coatings, rough surfaces, and a poor final product.

- Purity and Color Integrity: The grinding process must not contaminate the marble or generate excessive heat that could alter its chemical composition or natural color, which is a key aesthetic feature.

- Operational Efficiency: The process must be energy-efficient and cost-effective to keep material costs manageable for furniture makers.

- Environmental and Workplace Safety: Dust control and noise reduction are paramount to meet stringent international safety and environmental standards.

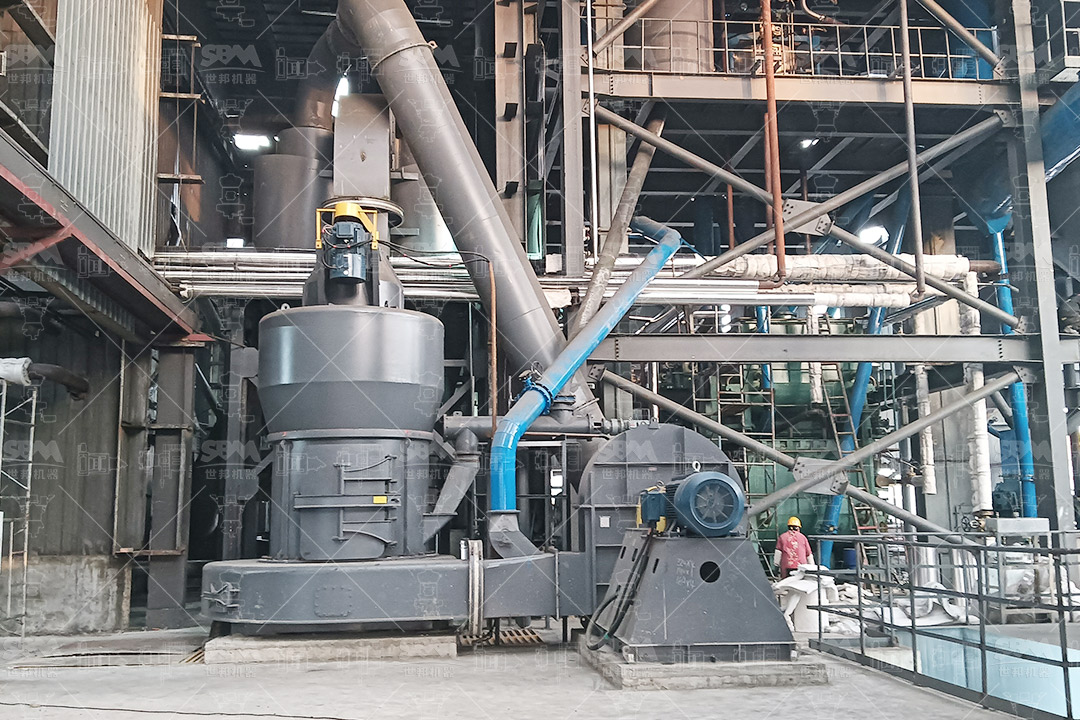

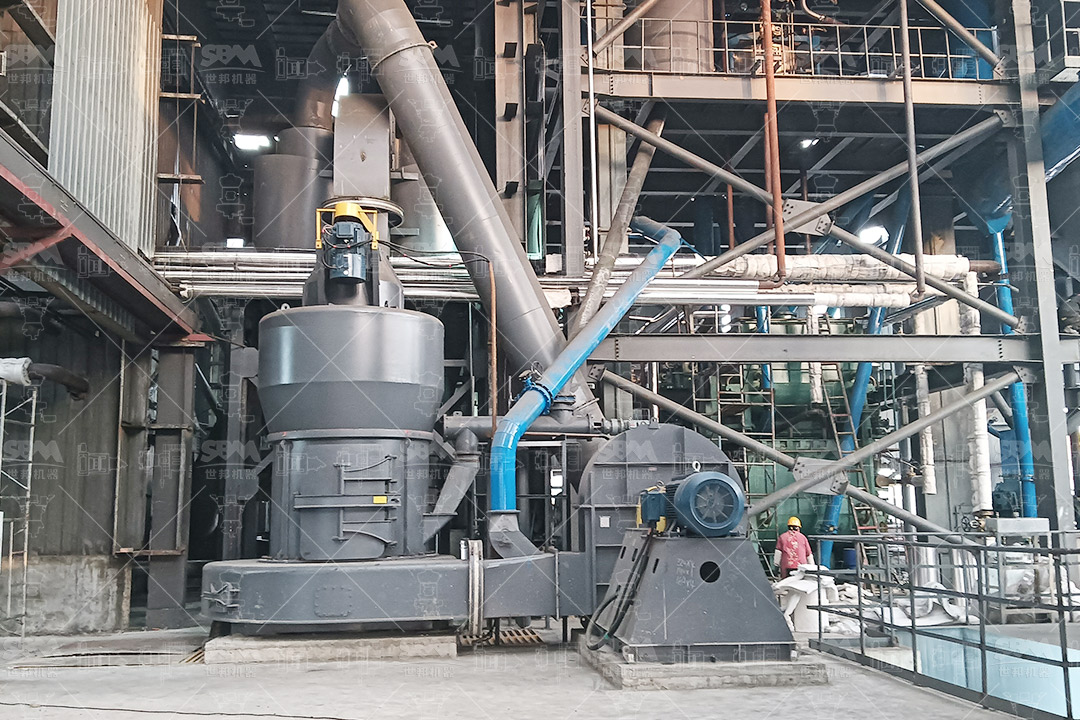

SCM Ultrafine Mill: The Premier Solution for Precision Grinding

To meet these exacting demands, our SCM Series Ultrafine Mill (45-5μm) stands out as the industry benchmark. This mill is engineered specifically for applications requiring the highest levels of fineness and purity, making it the ideal choice for furniture manufacturers sourcing the best marble powders.

Unmatched Technical Advantages

The SCM Ultrafine Mill incorporates several groundbreaking technologies that directly address the needs of the furniture sector:

- High-Efficiency & Energy Savings: With a capacity twice that of jet mills and energy consumption reduced by 30%, the SCM series offers a significantly lower operational cost, a crucial factor for cost-conscious production. Its intelligent control system features automatic feedback on product fineness, ensuring a consistently perfect grind without manual intervention.

- High-Precision Classification: The integrated vertical turbo-classifier is the core of its precision. It ensures accurate particle size切割 (cutting), guaranteeing that no coarse powder is mixed into the final product. This results in a perfectly uniform powder that creates smooth, flawless furniture surfaces.

- Durable and Stable Design: Furniture manufacturing is a continuous process. The SCM mill’s special material rollers and grinding rings have a lifespan extended by several times, reducing downtime for maintenance. The innovative bearing-free screw in the grinding chamber enhances operational stability, ensuring uninterrupted production runs.

- Eco-Friendly and Low Noise: The pulse dust collector exceeds international standards for efficiency, capturing over 99.9% of dust particles and protecting both the workforce and the environment. The integrated soundproofing room design keeps operational noise below 75dB, creating a much safer and more comfortable working environment.

Precise Specifications for Demanding Applications

| Model |

Processing Capacity (ton/h) |

Main Motor Power (kW) |

Input Size (mm) |

Output Fineness (mesh) |

| SCM800 |

0.5-4.5 |

75 |

≤20 |

325-2500 |

| SCM900 |

0.8-6.5 |

90 |

≤20 |

325-2500 |

| SCM1000 |

1.0-8.5 |

132 |

≤20 |

325-2500 |

| SCM1250 |

2.5-14 |

185 |

≤20 |

325-2500 |

| SCM1680 |

5.0-25 |

315 |

≤20 |

325-2500 |

The MTW Series: A Robust Alternative for Broader Applications

For furniture manufacturers who also work with other mineral-based materials or require slightly different fineness ranges, our MTW Series Trapezium Mill (600-45μm) presents a powerful and versatile alternative. While the SCM series targets the ultra-fine end of the spectrum, the MTW series excels in robust, high-capacity grinding from coarse to fine powders.

Key Features of the MTW Series

- Anti-Wear Shovel Design: Its combination shovel blades significantly reduce maintenance costs, while the curved design extends the life of the grinding roller, ensuring long-term reliability.

- Optimized Airflow: The curved air channel reduces energy loss and increases transmission efficiency, protected by high-strength wear plates.

- Integrated Gear Drive: With a transmission efficiency of up to 98%, this design saves space and reduces installation complexity and cost.

- High Capacity: Models like the MTW215G can process up to 45 tons per hour, making it suitable for large-scale furniture production facilities.

Conclusion: Investing in Quality from the Ground Up

The quality of furniture is built from the foundation materials upwards. By investing in advanced grinding technology like the SCM Ultrafine Mill or the MTW Series Trapezium Mill, manufacturers gain direct control over a critical component of their product’s value: the finish. These mills are not just pieces of industrial machinery; they are essential tools for achieving the precision, efficiency, and consistency required to compete and excel in the high-stakes world of quality furniture manufacturing. The ability to produce in-house, high-purity, ultra-fine marble powder translates directly into superior products, enhanced brand reputation, and ultimately, greater market success.