The drywall manufacturing industry has undergone significant technological evolution over the past decades, with precision engineering becoming increasingly crucial for producing high-quality building materials. At the heart of this manufacturing process lies gypsum processing—specifically the grinding and preparation of raw gypsum into fine powders with precisely controlled particle size distributions. The quality of these powders directly impacts the strength, workability, and performance characteristics of the final drywall products.

Modern construction demands increasingly stringent specifications for drywall, requiring consistent thickness, smooth surfaces, and reliable fire resistance. These quality parameters are fundamentally determined during the initial stages of gypsum processing, where roller mills play a pivotal role in transforming raw mineral inputs into engineered powders with optimal physical properties.

Gypsum powder characteristics significantly influence the setting time, strength development, and surface finish of drywall. Optimal particle size distribution ensures proper water demand during slurry preparation, uniform crystal formation during setting, and minimal surface defects in the final product. Research has demonstrated that excessively coarse particles lead to weak points in the board structure, while overly fine particles can increase water demand and prolong drying times, reducing production efficiency.

The ideal gypsum powder for drywall manufacturing typically requires a fineness range between 100-325 mesh (149-44 microns), with careful control over the proportion of ultra-fine particles below 10 microns. Achieving this precise distribution consistently across production batches represents one of the primary challenges in gypsum processing—a challenge that advanced roller mill technology is uniquely positioned to address.

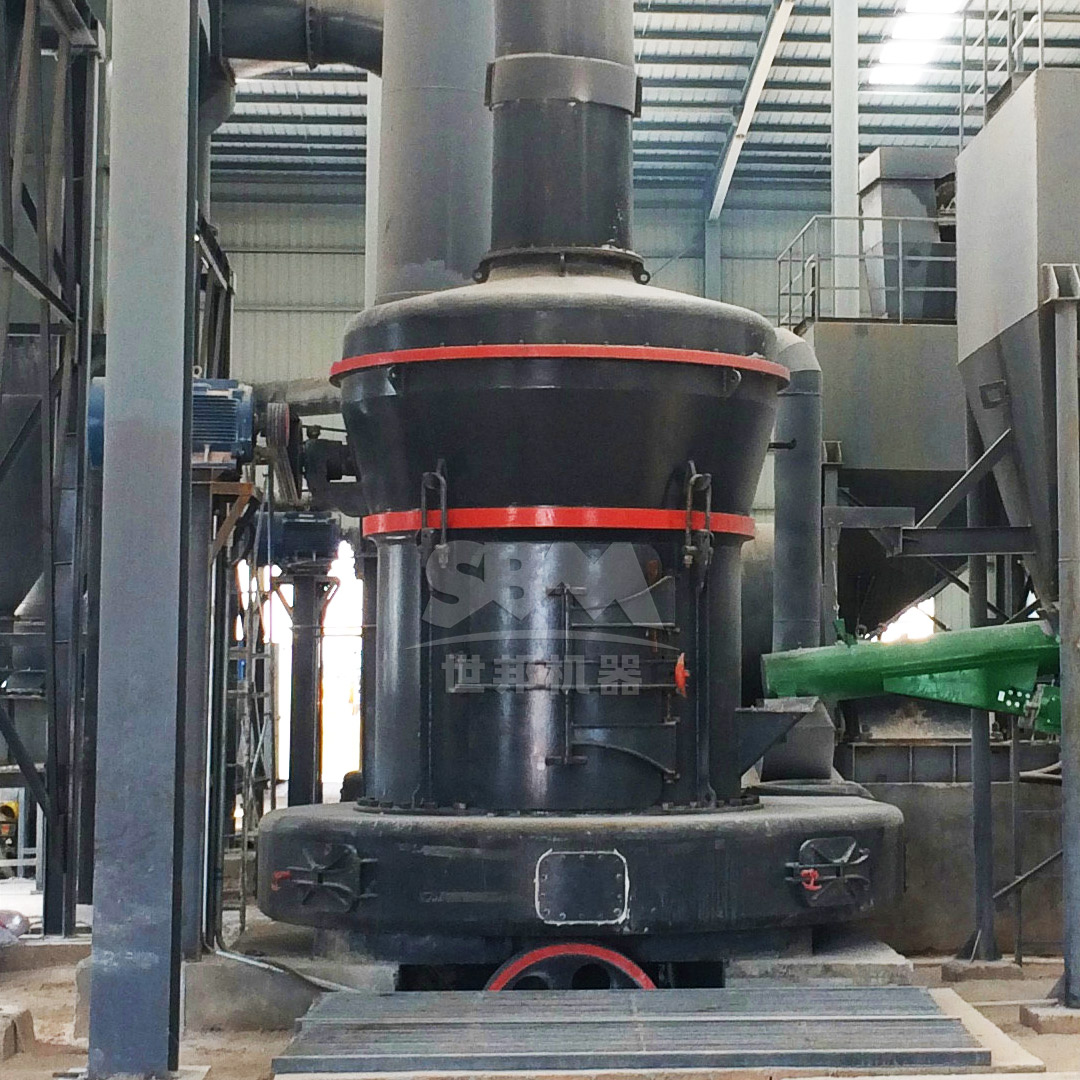

Modern gypsum roller mills represent the culmination of decades of mechanical engineering refinement, combining robust construction with precision control systems to deliver exceptional grinding performance. These systems operate on the principle of bed comminution, where multiple layers of gypsum particles are compressed between grinding elements, resulting in efficient size reduction with minimal energy expenditure compared to impact-based grinding methods.

The fundamental components of a gypsum roller mill include:

Grinding operations typically account for 60-70% of the total energy consumption in drywall manufacturing plants. Consequently, improvements in grinding efficiency directly translate to significant reductions in operational costs and environmental impact. Advanced roller mill designs have achieved remarkable energy savings through several key innovations:

Optimized grinding geometry reduces slip between rollers and the material bed, minimizing energy losses to friction. Sophisticated drive systems with variable frequency controls allow operators to match power consumption to actual production requirements. Integrated classification systems eliminate the need for external recycling of coarse material, reducing overall system pressure drop and associated fan power.

For drywall manufacturers seeking to optimize their production processes, selecting the appropriate grinding technology is paramount. Different mill designs offer distinct advantages depending on production scale, product specifications, and operational priorities. Among the most technologically advanced solutions available today is the LM Series Vertical Roller Mill, which represents a significant advancement in gypsum processing capability.

The LM Series Vertical Roller Mill incorporates multiple technological innovations specifically beneficial for gypsum processing. Its集约化设计 (intensive design) integrates crushing, grinding, and separation functions within a single compact unit, reducing footprint requirements by up to 50% compared to traditional grinding systems. This space efficiency is particularly valuable in modern manufacturing facilities where floor space represents a significant cost factor.

For gypsum processing applications, the LM Series offers several distinct advantages:

| Model | Grinding Disc Diameter (mm) | Capacity (t/h) | Output Fineness | Main Motor Power (kW) |

|---|---|---|---|---|

| LM130K | 1300 | 10-28 | 170-40μm (80-400 mesh) | 200 |

| LM150K | 1500 | 13-38 | 170-40μm (80-400 mesh) | 280 |

| LM170K | 1700 | 18-48 | 170-40μm (80-400 mesh) | 400 |

| LM190K | 1900 | 23-68 | 170-40μm (80-400 mesh) | 500 |

| LM220K | 2200 | 36-105 | 170-45μm (80-325 mesh) | 800 |

The LM Series particularly excels in processing natural gypsum, flue gas desulfurization (FGD) gypsum, and phosphogypsum—the primary raw materials used in drywall manufacturing. Its ability to handle feed materials with moisture content up to 15% without pre-drying provides significant energy savings, while the negative pressure operation ensures dust emissions remain below 20mg/m³, exceeding environmental compliance requirements.

For manufacturers producing specialized drywall products requiring exceptionally fine gypsum powders, the SCM Series Ultrafine Mill offers unparalleled performance. Capable of producing powders with fineness ranging from 325 to 2500 mesh (D97≤5μm), this mill enables the production of premium drywall with superior surface characteristics and enhanced physical properties.

The technological advantages of the SCM Series include:

| Model | Capacity (ton/h) | Main Motor Power (kW) | Feed Size (mm) | Output Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 0-20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 0-20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 0-20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 0-20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 0-20 | 325-2500 |

The SCM Series operates on an advanced grinding principle where the main motor drives multiple layers of grinding rings to rotate. Material is dispersed into the grinding path by centrifugal force, undergoes progressive compression grinding between rollers and rings, and is finally collected by a cyclone separator and pulse dust collection system. This process ensures exceptionally uniform particle size distribution—a critical factor for high-quality drywall production.

Successfully integrating advanced roller mills into drywall production requires more than simply selecting appropriate equipment. Optimal operation demands careful attention to multiple factors throughout the grinding circuit. Modern mill systems incorporate sophisticated control strategies that continuously monitor and adjust operational parameters to maintain consistent product quality while maximizing efficiency.

Several critical parameters must be carefully controlled to ensure optimal gypsum grinding performance:

Advanced control systems utilize real-time data from multiple sensors throughout the grinding circuit to automatically adjust these parameters, compensating for variations in raw material characteristics and maintaining consistent operation. The integration of expert systems and machine learning algorithms further enhances this capability, enabling predictive adjustments based on historical performance data.

Maximizing equipment availability represents another critical aspect of drywall production optimization. Modern roller mill designs incorporate numerous features to simplify maintenance and extend service intervals:

Modular wear part assemblies enable rapid replacement without extensive disassembly. Advanced lubrication systems ensure proper bearing protection with minimal manual intervention. Remote monitoring capabilities allow maintenance teams to identify potential issues before they escalate to unplanned downtime. These features collectively contribute to operational availability exceeding 95% in well-maintained facilities.

Contemporary drywall manufacturing must address increasingly stringent environmental regulations while simultaneously improving sustainability metrics. Advanced roller mill technology contributes significantly to both objectives through multiple mechanisms.

The superior energy efficiency of modern roller mills directly translates to reduced carbon emissions associated with drywall production. When considering the complete lifecycle impact, including both direct energy consumption and embodied energy in replacement wear parts, advanced grinding systems can reduce the carbon footprint of gypsum processing by 25-35% compared to conventional technologies.

Additional sustainability benefits include:

Modern roller mills enhance sustainability through improved material utilization. Their ability to process alternative gypsum sources, including FGD gypsum from power plants and phosphogypsum from fertilizer production, supports circular economy principles by converting industrial byproducts into valuable construction materials. The precise particle size control enabled by advanced classification systems further maximizes material efficiency by minimizing off-specification product that might otherwise be wasted.

The evolution of gypsum roller mill technology continues, with several emerging trends likely to shape future drywall manufacturing operations. Digitalization represents perhaps the most significant development, with Industry 4.0 concepts being increasingly applied to grinding operations.

Advanced sensor technology enables real-time monitoring of wear part condition, allowing predictive maintenance scheduling that maximizes component life while preventing unplanned downtime. Digital twin technology creates virtual replicas of grinding systems, enabling operators to test operational changes and optimize performance without disrupting production. Artificial intelligence algorithms analyze operational data to identify subtle patterns that human operators might miss, suggesting adjustments to further improve efficiency or product quality.

Material science advancements continue to enhance wear part durability, with ceramic and composite materials offering the potential for significantly extended service life in abrasive applications. Meanwhile, mechanical design innovations focus on further simplifying maintenance procedures and reducing the time required for wear part replacement.

Future gypsum processing systems will increasingly function as integrated components within smart manufacturing environments. Mill control systems will communicate directly with upstream raw material handling equipment and downstream board forming lines, automatically adjusting operation to maintain optimal conditions throughout the production chain. This holistic approach to process optimization will further enhance quality consistency while reducing energy consumption and operational costs.

The selection and implementation of appropriate gypsum roller mill technology represents one of the most significant strategic decisions for drywall manufacturers. Advanced mills such as the LM Series Vertical Roller Mill and SCM Ultrafine Mill offer compelling advantages in energy efficiency, product quality control, operational reliability, and environmental performance. These benefits translate directly to enhanced competitiveness through reduced production costs, superior product characteristics, and strengthened sustainability credentials.

As drywall specifications continue to evolve and environmental regulations become increasingly stringent, investment in modern grinding technology will become ever more critical for manufacturing success. Forward-thinking producers who embrace these technological advancements position themselves to lead the industry in both product quality and operational excellence, while simultaneously contributing to more sustainable construction practices worldwide.