The paint and coating industry demands precise control over particle size distribution to achieve optimal properties such as gloss, opacity, durability, and rheology. Ultrafine grinding technology plays a pivotal role in producing high-performance formulations by enabling the production of fine and consistent powders. This article explores the importance of ultrafine milling in paint and coating applications and highlights advanced solutions that meet these stringent requirements.

Particle size directly influences key characteristics of paints and coatings. Finer particles enhance color strength, improve dispersion stability, and provide smoother surface finishes. For instance, titanium dioxide (TiO2) pigments ground to sub-micron levels exhibit superior opacity and brightness. Similarly, extenders and fillers like calcium carbonate and talc require precise grinding to achieve desired rheological properties and film integrity.

Modern ultrafine mills leverage innovative designs to achieve precise particle size control, high efficiency, and low operational costs. Key technologies include vertical roller mills, pendulum mills, and specialized ultrafine grinders. These systems incorporate features such as advanced classification, wear-resistant materials, and intelligent control systems to meet the demands of the paint and coating industry.

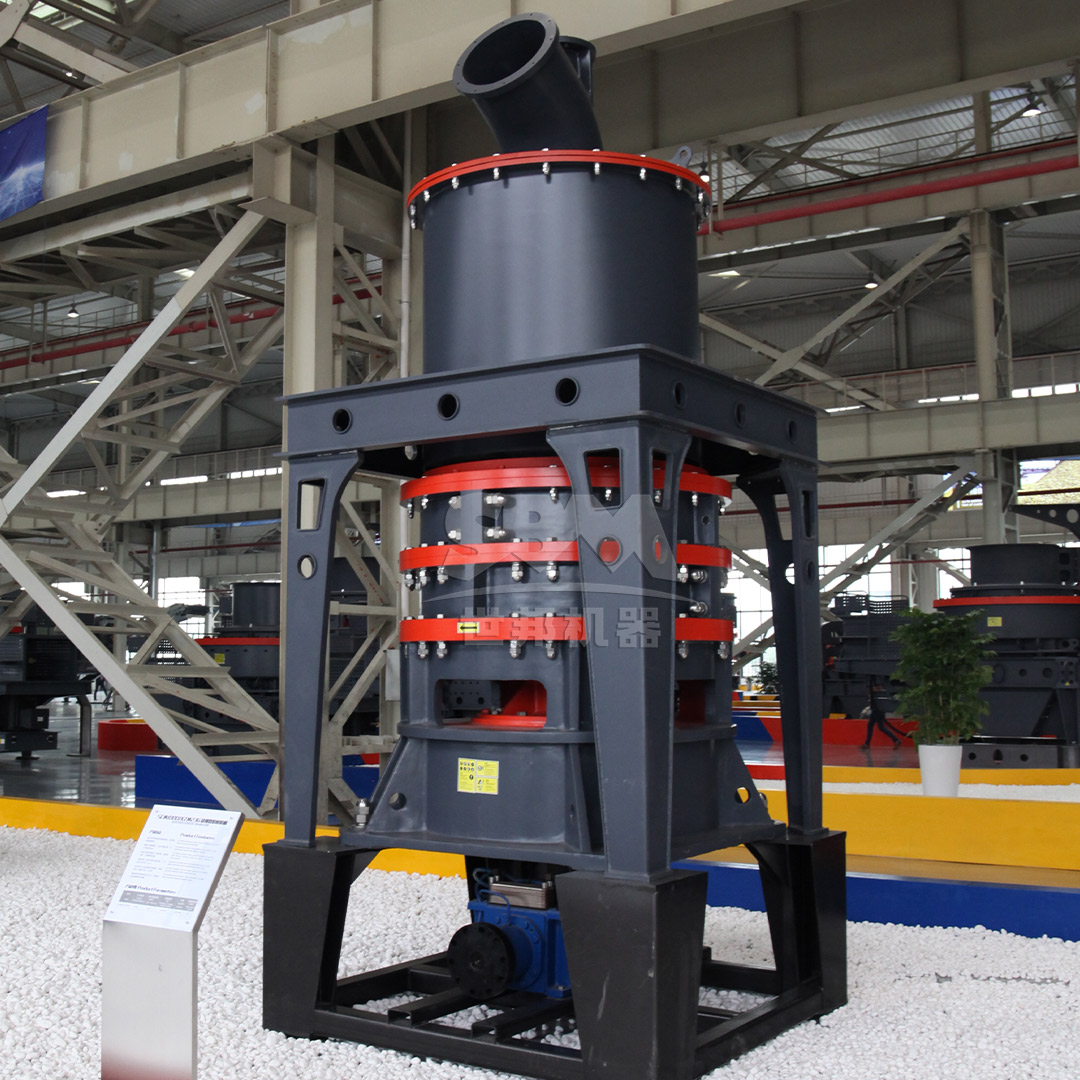

For applications requiring extremely fine powders (D97 ≤ 5μm), the SCM Ultrafine Mill stands out as an ideal solution. This mill is designed to produce powders in the range of 325–2500 mesh, making it suitable for high-value pigments and additives. Its key advantages include:

The SCM mill operates by driving three-layer grinding rings via a main motor. Material is dispersed into the grinding path by centrifugal force, progressively crushed by rollers, and finally collected by a cyclone and pulse dust removal system. With models ranging from SCM800 (0.5–4.5 t/h) to SCM1680 (5–25 t/h), it offers scalability for various production needs.

| Model | Processing Capacity (t/h) | Main Motor Power (kW) | Output Fineness (mesh) |

|---|---|---|---|

| SCM800 | 0.5–4.5 | 75 | 325–2500 |

| SCM900 | 0.8–6.5 | 90 | 325–2500 |

| SCM1000 | 1.0–8.5 | 132 | 325–2500 |

| SCM1250 | 2.5–14 | 185 | 325–2500 |

| SCM1680 | 5.0–25 | 315 | 325–2500 |

For formulations requiring slightly coarser powders (30–325 mesh), the MTW Series Trapezium Mill offers a robust and efficient solution. This mill handles inputs up to 50mm and delivers outputs ranging from 30 to 325 mesh (0.038mm), with capacities from 3 to 45 t/h. Its advantages include:

The MTW mill works by driving grinding rollers to rotate around a central axis while self-rotating to generate centrifugal force. Shovels throw material into the space between rollers and grinding rings, where挤压粉碎 occurs, and a classification system ensures precise particle size control. Models like MTW110 (3–9 t/h) and MTW215G (15–45 t/h) cater to diverse production scales.

Ultrafine mills are critical in processing various materials used in paints and coatings:

Ultrafine milling technology is indispensable for producing high-performance paint and coating formulations. Equipment like the SCM Ultrafine Mill and MTW Series Trapezium Mill offer precision, efficiency, and reliability, enabling manufacturers to achieve desired product qualities while optimizing costs. As industry demands evolve, advanced grinding solutions will continue to play a vital role in driving innovation and quality in the coatings sector.