Talc, a hydrated magnesium silicate, is a critical mineral in numerous industrial applications due to its unique properties such as softness, chemical inertness, and lamellar structure. The performance of talc in high-value sectors like plastics, paints, coatings, pharmaceuticals, and cosmetics is heavily dependent on its particle size distribution, purity, and surface characteristics. Achieving the desired fineness and quality requires advanced milling technologies that can deliver precise particle size control, high throughput, and energy efficiency while maintaining operational reliability and environmental compliance.

Traditional milling methods often fall short in meeting the stringent requirements of modern industrial processes. Issues such as broad particle size distribution, contamination from grinding media, high energy consumption, and excessive heat generation can compromise product quality and increase operational costs. Therefore, selecting the right milling equipment is paramount for producers aiming to enhance their product performance and market competitiveness.

Processing talc to meet industrial standards involves several challenges. The mineral’s softness (1 on the Mohs scale) makes it prone to over-grinding, which can lead to excessive fines and reduced efficiency in certain applications. Additionally, talc’s plate-like structure must be preserved during milling to maintain its functional properties, such as barrier effects in plastics and smoothness in cosmetics. Contamination from wear parts is another critical concern, as even minimal impurities can affect the color and performance of the final product.

Energy consumption is a significant factor in milling operations, with traditional ball mills and Raymond mills often being inefficient for ultra-fine grinding. Environmental regulations also demand low dust emissions and noise levels, necessitating enclosed systems with effective dust collection and noise suppression features. Addressing these challenges requires milling solutions that combine precision, efficiency, durability, and sustainability.

Recent advancements in milling technology have led to the development of equipment capable of overcoming these challenges. Modern mills incorporate features such as precision classification systems, wear-resistant materials, intelligent control systems, and eco-friendly designs. These innovations enable producers to achieve consistent product quality, reduce operational costs, and minimize environmental impact.

For applications requiring ultra-fine talc powders with tight particle size distributions, the SCM Ultrafine Mill stands out as an ideal solution. This mill is engineered to produce powders ranging from 325 to 2500 mesh (D97 ≤5μm), making it suitable for high-performance industrial chemicals where fineness and uniformity are critical.

The SCM Ultrafine Mill operates on a layered grinding principle. The main motor drives multiple grinding rings to rotate, and material is fed into the grinding chamber where it is subjected to centrifugal force and ground between the rollers and rings. The integrated vertical turbine classifier ensures precise particle size切割, preventing coarse particles from contaminating the final product. This results in a uniform powder with excellent flow characteristics and surface area, ideal for enhancing the properties of talc in various applications.

Key advantages of the SCM Ultrafine Mill include its high efficiency and energy savings. It offers twice the capacity of jet mills while reducing energy consumption by 30%. The intelligent control system automatically adjusts operational parameters based on real-time feedback of product fineness, ensuring consistent quality and optimizing performance. The mill’s durable construction features special material rollers and grinding rings that significantly extend service life, reducing maintenance costs and downtime. Additionally, the enclosed design with pulse dust removal and soundproofing ensures emissions are below international standards and noise levels are kept under 75dB.

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Input Size (mm) | Output Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | ≤20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | ≤20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | ≤20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | ≤20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | ≤20 | 325-2500 |

With its robust design and advanced features, the SCM Ultrafine Mill is highly recommended for producers seeking to manufacture high-purity talc powders for demanding applications such as premium cosmetics, pharmaceuticals, and high-end polymers.

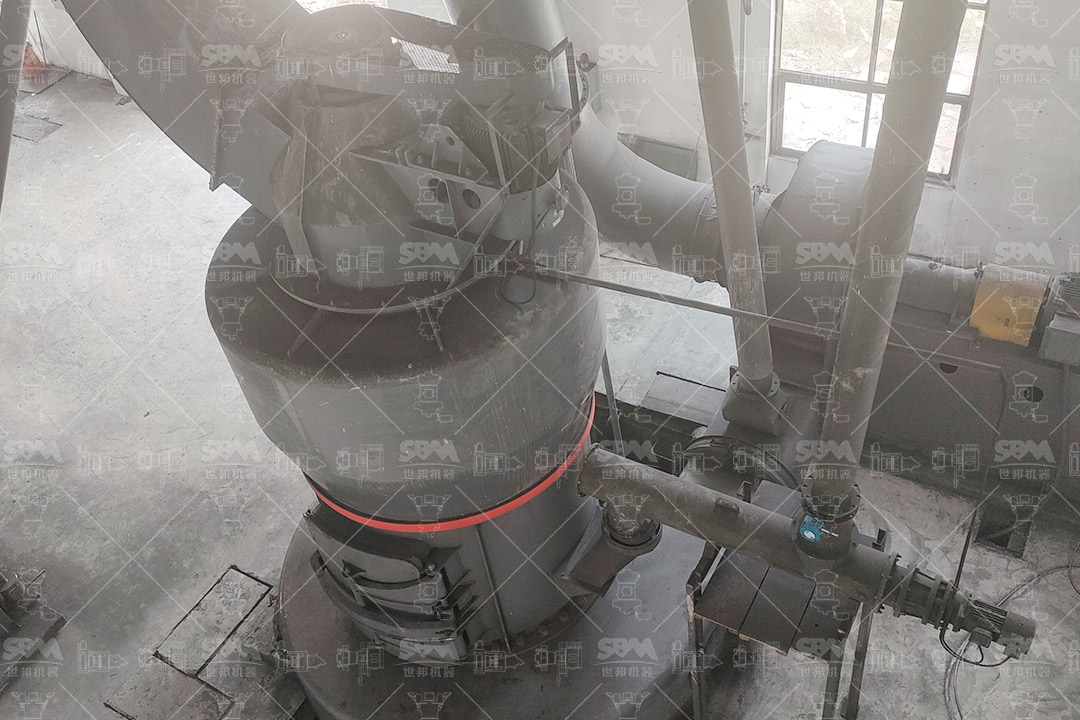

For talc processing requiring a balance between fineness and high capacity, the MTW Series Trapezium Mill offers an excellent solution. This mill is designed to handle input sizes up to 50mm and produce powders from 30 to 325 mesh (up to 0.038mm), with processing capacities ranging from 3 to 45 tons per hour depending on the model.

The MTW Mill features a curved air duct design that minimizes energy loss and improves material transmission efficiency. The wear-resistant shovel blades and grinding rollers are designed for longevity, reducing maintenance frequency and costs. The integral transmission with bevel gears ensures high transmission efficiency (up to 98%) and stable operation. The mill’s grinding mechanism involves the main motor driving the grinding rollers to rotate around the central shaft, while the shovel blades throw material into the space between the rollers and grinding ring for compression and grinding. The built-in classifier ensures precise control over product fineness.

Notable technical advantages of the MTW Series include its anti-wear shovel design, which features combined shovel slices that lower maintenance costs, and the curved air duct that enhances airflow and reduces energy consumption. The锥齿轮整体传动 system saves space and installation costs, while the耐磨蜗壳结构 improves air classification efficiency and reduces maintenance by 30%. The mill is also equipped with advanced pulse dust collection technology, ensuring environmental compliance.

With models like MTW138Z offering capacities up to 17 tons per hour and MTW215G handling up to 45 tons per hour, the MTW Series is suitable for large-scale talc production operations. Its versatility makes it ideal for applications in paints, coatings, ceramics, and other industrial sectors where consistent quality and high throughput are essential.

Selecting the appropriate milling technology is crucial for optimizing talc processing and meeting the demands of high-performance industrial chemicals. The SCM Ultrafine Mill and MTW Series Trapezium Mill represent cutting-edge solutions that address the key challenges of precision, efficiency, durability, and environmental sustainability. By leveraging these advanced technologies, producers can enhance their product quality, reduce operational costs, and gain a competitive edge in the market.

Investing in modern milling equipment not only improves process efficiency but also supports sustainable manufacturing practices. As industry standards continue to evolve, adopting innovative grinding solutions will be essential for staying ahead in the competitive landscape of industrial minerals.