Carbon black is a critical additive in rubber compounding, serving as both a reinforcing filler and a conductivity enhancer. The electrical conductivity of rubber compounds is significantly influenced by the particle size, structure, and dispersion quality of carbon black. Proper grinding and processing of carbon black are essential to achieve the desired electrical properties while maintaining the mechanical integrity of the final rubber product. This article explores the role of advanced grinding technology in optimizing carbon black for conductive rubber applications.

Electrical conductivity in rubber is achieved through the formation of continuous conductive pathways by carbon black particles within the polymer matrix. The efficiency of these pathways depends on several factors:

Finer carbon black particles with narrow size distribution create more contact points, leading to improved conductivity. However, achieving optimal particle characteristics requires precise grinding technology capable of producing consistent, ultra-fine powders without compromising production efficiency.

Processing carbon black for conductive rubber applications presents unique challenges:

Traditional grinding methods often fail to meet these requirements, leading to inconsistent conductivity and compromised rubber properties.

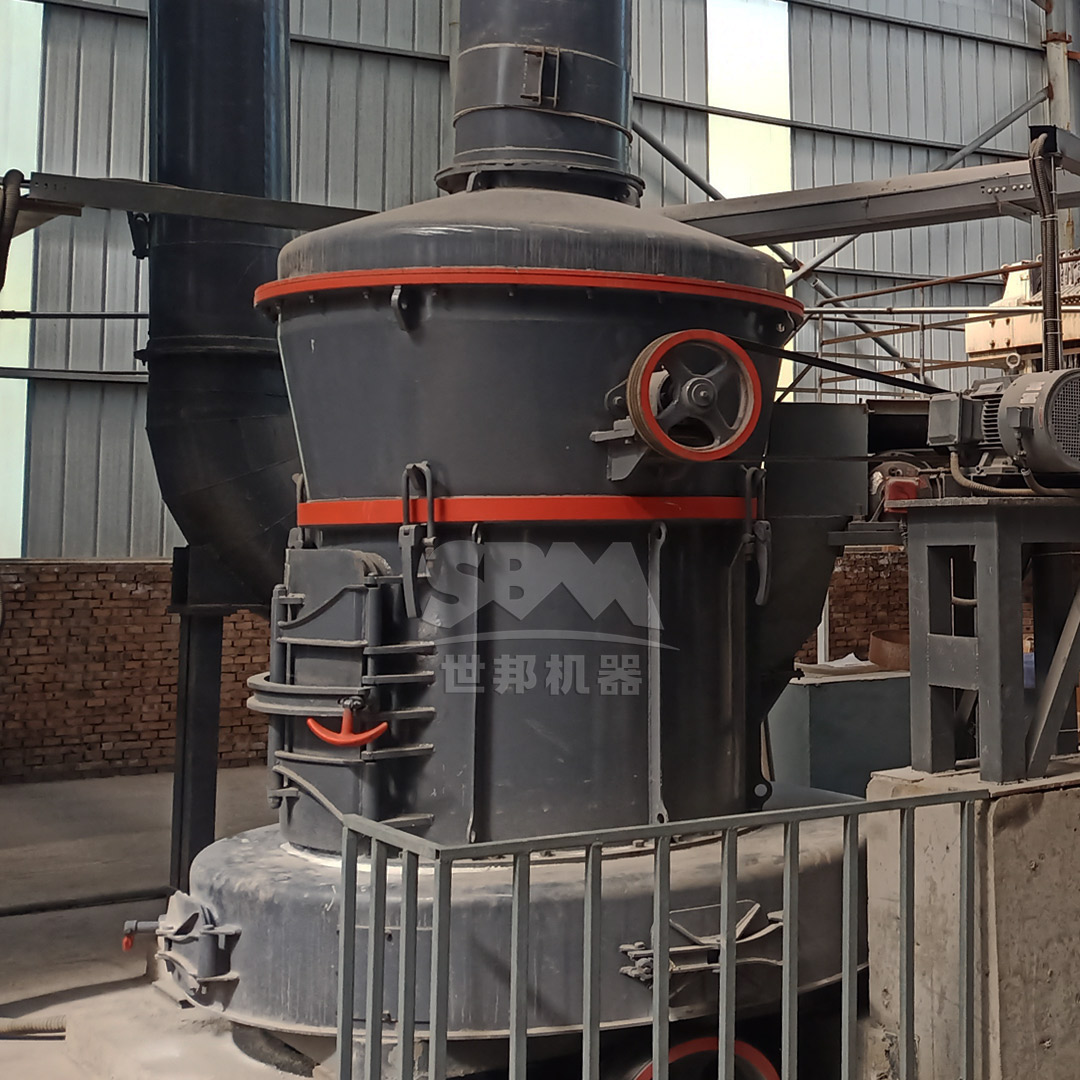

For applications requiring the finest carbon black particles, the SCM Ultrafine Mill represents the pinnacle of grinding technology. This advanced system is specifically engineered to produce carbon black powders with exceptional consistency and particle size control.

The SCM Ultrafine Mill offers several critical advantages for conductive rubber applications:

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Output Fineness (mesh) |

|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 325-2500 |

The grinding mechanism of the SCM Ultrafine Mill involves multiple layers of grinding rings and rollers that progressively reduce particle size through centrifugal force and mechanical pressure. This multi-stage approach ensures gentle yet efficient size reduction while preserving the essential structure of carbon black particles.

For applications requiring high-volume production of conductive carbon black, the MTW Series Trapezium Mill offers an optimal balance of capacity and precision. This robust system is designed for continuous operation with minimal maintenance requirements.

Key features of the MTW Series include:

The MTW Series operates through a combination of grinding roller rotation around the central axis and simultaneous self-rotation, creating centrifugal force that efficiently processes carbon black while maintaining particle integrity.

The relationship between carbon black particle size and electrical conductivity follows a well-established pattern. As particle size decreases below critical thresholds, conductivity increases exponentially due to the formation of more extensive conductive networks. However, this relationship is not linear, and optimal conductivity requires careful control of the entire particle size distribution.

Research has demonstrated that:

Grinding carbon black to sub-micron sizes requires substantial energy input. Advanced grinding systems must balance particle size reduction with energy efficiency to maintain economic viability. The SCM Ultrafine Mill addresses this challenge through:

In applications requiring controlled static dissipation, such as conveyor belts and flooring, carbon black grinding quality directly impacts performance. A case study involving the SCM1000 Ultrafine Mill demonstrated:

For applications requiring true electrical conductivity, such as EMI shielding and electrodes, ultra-fine carbon black is essential. Implementation of the SCM1250 system resulted in:

The future of conductive rubber compounds lies in nanotechnology integration. Advanced grinding systems are evolving to handle carbon nanomaterials while maintaining industrial-scale production capabilities. Key developments include:

Modern grinding technology must address environmental concerns while maintaining performance. The latest generation of grinding mills incorporates:

The selection of appropriate grinding technology is crucial for optimizing carbon black performance in conductive rubber applications. The SCM Ultrafine Mill and MTW Series Trapezium Mill represent advanced solutions capable of meeting the demanding requirements of modern rubber compounding. Through precise particle size control, efficient operation, and consistent quality output, these systems enable manufacturers to achieve superior conductivity while maintaining economic viability. As rubber applications continue to evolve toward higher performance standards, advanced grinding technology will play an increasingly important role in material development and production efficiency.