Petroleum coke (petcoke) is a carbonaceous solid derived from oil refinery coker units or other cracking processes. As a valuable industrial fuel and raw material, petcoke requires specialized grinding equipment to achieve the precise particle size distribution necessary for various applications. High-temperature resistant grinding mills are particularly crucial for processing calcined petroleum coke, which undergoes thermal treatment at temperatures exceeding 1200°C to remove volatile matter and increase carbon content.

The grinding of petroleum coke presents unique challenges due to its abrasive nature, variable hardness, and the potential for dust explosion hazards. Specialized mill designs must address these concerns while maintaining efficiency, product quality, and operational safety. This article explores the technical requirements for petroleum coke grinding and introduces advanced milling solutions specifically engineered for this demanding application.

Petroleum coke varies significantly in properties depending on the crude source and processing conditions. Key characteristics affecting grindability include:

High-temperature grinding is often necessary for calcined petroleum coke applications. Mills must withstand operational temperatures up to 200°C while maintaining dimensional stability and material properties. Thermal expansion management, heat-resistant materials, and specialized cooling systems are essential design considerations.

Petroleum coke dust can form explosive mixtures with air. Grinding systems must incorporate explosion prevention measures including:

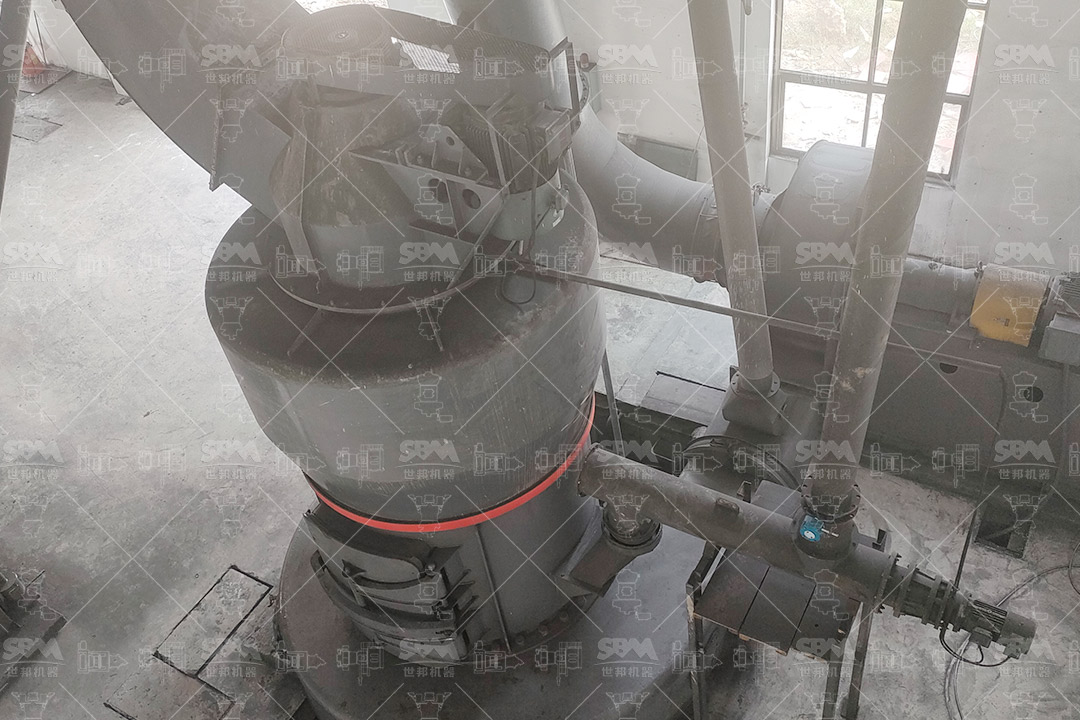

For applications requiring ultra-fine petroleum coke powders (325-2500 mesh), the SCM Ultrafine Mill represents the state-of-the-art in grinding technology. This mill is specifically engineered to handle the unique challenges of petroleum coke processing with several distinctive advantages:

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Feed Size (mm) | Product Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 0-20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 0-20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 0-20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 0-20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 0-20 | 325-2500 |

The SCM Ultrafine Mill operates through a multi-layer grinding principle where the main motor drives three layers of grinding rings to rotate. Material is dispersed into the grinding path by centrifugal force, undergoes roller compression crushing, and is progressively ground through multiple layers. Final powder collection is accomplished through a cyclone collector and pulse dust removal system.

For applications requiring medium to fine petroleum coke powders (30-325 mesh), the MTW Series Trapezium Mill offers robust performance and exceptional reliability. This European-style grinding mill incorporates several patented technologies specifically beneficial for petroleum coke processing:

The MTW Series operates through a principle where the main motor drives grinding rollers to revolve around the central axis while simultaneously rotating to generate centrifugal force. Shovel blades throw material between the grinding ring and rollers to form a material layer, achieving efficient crushing through compression with a precision classification system controlling final particle size.

Selecting the appropriate grinding mill begins with accurate capacity assessment. Consider both immediate needs and future expansion requirements. For petroleum coke applications, it’s essential to account for material density variations and potential changes in feed characteristics over time.

Different applications demand specific particle size distributions:

Beyond technical specifications, several operational factors influence mill selection:

A major aluminum producer implemented an SCM1680 Ultrafine Mill for grinding calcined petroleum coke at 180°C for anode production. The installation achieved:

The success of this installation demonstrates how advanced grinding technology specifically engineered for high-temperature petroleum coke applications can deliver significant operational improvements across multiple metrics.

The evolution of petroleum coke grinding technology continues with several emerging trends:

As environmental regulations tighten and efficiency demands increase, grinding mill manufacturers continue to innovate. The SCM and MTW series represent current best practices, with ongoing development focused on further reducing operational costs while maintaining product quality and equipment reliability.

High-temperature resistant grinding mills for petroleum coke represent specialized equipment engineered to address the unique challenges of this application. Through advanced design features, durable construction, and precision classification systems, modern grinding mills deliver the performance, reliability, and efficiency required by today’s industrial operations.

The selection between ultra-fine grinding solutions like the SCM series and medium-fine options like the MTW series depends on specific application requirements, with both offering distinct advantages for different petroleum coke processing scenarios. As technology continues to evolve, these grinding systems will play an increasingly important role in maximizing the value of petroleum coke across diverse industrial applications.