In the coating production industry, achieving precise particle size distribution and maintaining high product quality are critical factors that directly impact the final product’s performance, appearance, and durability. Hammer mills play a fundamental role in this process, serving as primary size reduction equipment that transforms raw materials into fine powders suitable for coating formulations. This article explores the intricate relationship between hammer mill operation and the resulting particle characteristics in coating production.

The efficiency of a hammer mill in coating applications depends on multiple factors, including hammer design, rotor speed, screen selection, and feed material properties. Understanding these parameters is essential for optimizing both particle size distribution and product quality while maintaining operational efficiency.

Hammer mills operate on the principle of impact-based size reduction, where rapidly rotating hammers strike material particles, causing them to fracture into smaller fragments. The basic components include a rotor assembly with multiple hammers, a grinding chamber, and a screen that determines the maximum particle size exiting the mill.

The size reduction process occurs through three primary mechanisms: impact (particles striking hammers or chamber walls), attrition (particle-to-particle collisions), and shear (cleavage along natural fracture lines). The relative contribution of each mechanism depends on the hammer mill design and operating parameters.

Several critical parameters govern hammer mill performance in coating production:

| Parameter | Impact on Particle Size | Impact on Product Quality |

|---|---|---|

| Rotor Speed | Higher speeds produce finer particles but may increase heat generation | Excessive speed can degrade heat-sensitive materials |

| Hammer Design | Different hammer shapes create varying impact patterns | Proper design minimizes contamination from wear |

| Screen Size | Determines maximum particle size exiting the mill | Affects particle size distribution width |

| Feed Rate | Optimal rates ensure proper residence time | Overfeeding reduces efficiency and increases variability |

Controlling particle size distribution is paramount in coating production, as it directly influences key product properties such as opacity, gloss, viscosity, and film formation characteristics. Hammer mills offer several advantages for achieving precise particle size control in coating applications.

The screen or grate surrounding the rotor assembly represents the primary method for controlling particle size in hammer mills. Screen openings determine the maximum particle dimension that can exit the grinding chamber. For coating applications, screens with openings ranging from 0.5 to 3.0 mm are commonly employed, depending on the required fineness of the final product.

Screen configuration also affects particle size distribution. Thicker screens with precisely sized perforations provide more consistent particle sizing, while thinner screens may allow occasional oversized particles to pass through due to flexing during operation. The screen open area percentage influences throughput capacity and residence time, both of which impact the final particle size distribution.

Rotor speed significantly influences the impact energy transferred to particles. Higher rotational speeds generate greater impact forces, resulting in finer particles but potentially increasing heat generation, which can be detrimental to heat-sensitive coating ingredients. Modern hammer mills for coating applications often feature variable frequency drives that allow operators to optimize rotor speed for different materials.

Hammer configuration—including the number of hammers, their arrangement on the rotor, and their design—affects the grinding efficiency and particle size distribution. Multiple smaller hammers create more impact points per revolution, potentially yielding a narrower particle size distribution, while fewer larger hammers may be more suitable for tougher materials.

Beyond particle size, hammer mill operation significantly influences several critical quality parameters in coating production. Understanding these relationships enables manufacturers to optimize their processes for superior end products.

For pigmented coatings, the degree of pigment dispersion directly affects color strength, hue, and consistency. Hammer mills contribute to pigment dispersion by breaking down agglomerates and ensuring uniform particle size distribution. Inadequate milling can result in color shifts, reduced opacity, and uneven appearance in the final coating film.

The impact and shear forces in hammer mills help separate primary pigment particles while minimizing damage to their crystalline structure, which is essential for maintaining color properties. Optimal operation ensures complete dispersion without over-processing, which could degrade color performance.

Particle size distribution influences several key film properties in coatings, including:

Hammer mills capable of producing consistent, narrow particle size distributions contribute significantly to achieving these desirable film characteristics.

Modern hammer mill designs incorporate several technological advancements that enhance their performance in coating production applications. These innovations address common challenges such as heat generation, wear contamination, and particle size control.

Many coating ingredients are heat-sensitive, requiring careful temperature management during milling. Advanced hammer mills may feature integrated cooling systems, such as water-jacketed grinding chambers or cryogenic grinding options, to maintain optimal processing temperatures and preserve material properties.

In coating production, contamination from milling equipment wear can adversely affect product quality, particularly in applications requiring high purity. Modern hammer mills address this concern through:

These features are especially important when processing abrasive materials or when producing coatings for sensitive applications such as food packaging or medical devices.

Maximizing hammer mill efficiency while maintaining product quality requires a systematic approach to operation and maintenance. Several strategies can enhance performance in coating production applications.

Regular maintenance is essential for consistent hammer mill performance. Key maintenance activities include:

| Maintenance Activity | Frequency | Impact on Performance |

|---|---|---|

| Hammer inspection/replacement | Based on throughput | Maintains impact efficiency and particle size control |

| Screen inspection | Weekly or per batch | Ensures proper particle size limitation |

| Bearing lubrication | As manufacturer recommended | Prevents unexpected downtime |

| Rotor balance check | Quarterly or after hammer changes | Reduces vibration and wear |

Modern hammer mills often incorporate advanced monitoring systems that track key operational parameters such as power consumption, temperature, and vibration. These systems can provide early warning of potential issues and help maintain consistent product quality. Integration with plant control systems allows for automated adjustment of operating parameters based on real-time feedback.

While traditional hammer mills serve many coating applications effectively, specialized grinding equipment often provides superior performance for specific requirements, particularly when ultra-fine particles or narrow size distributions are needed. Our company offers advanced solutions specifically designed for coating production challenges.

For coating applications requiring exceptionally fine particles with narrow size distributions, our SCM Series Ultrafine Mill represents an ideal solution. This advanced grinding system delivers output fineness ranging from 325 to 2500 mesh (D97 ≤ 5μm), making it perfectly suited for high-performance coatings where superior finish quality is paramount.

The SCM Ultrafine Mill incorporates several technological advantages specifically beneficial for coating production:

With models ranging from the SCM800 (0.5-4.5 ton/h capacity) to the SCM1680 (5.0-25 ton/h capacity), coating manufacturers can select the ideal configuration for their specific production requirements while maintaining the highest quality standards.

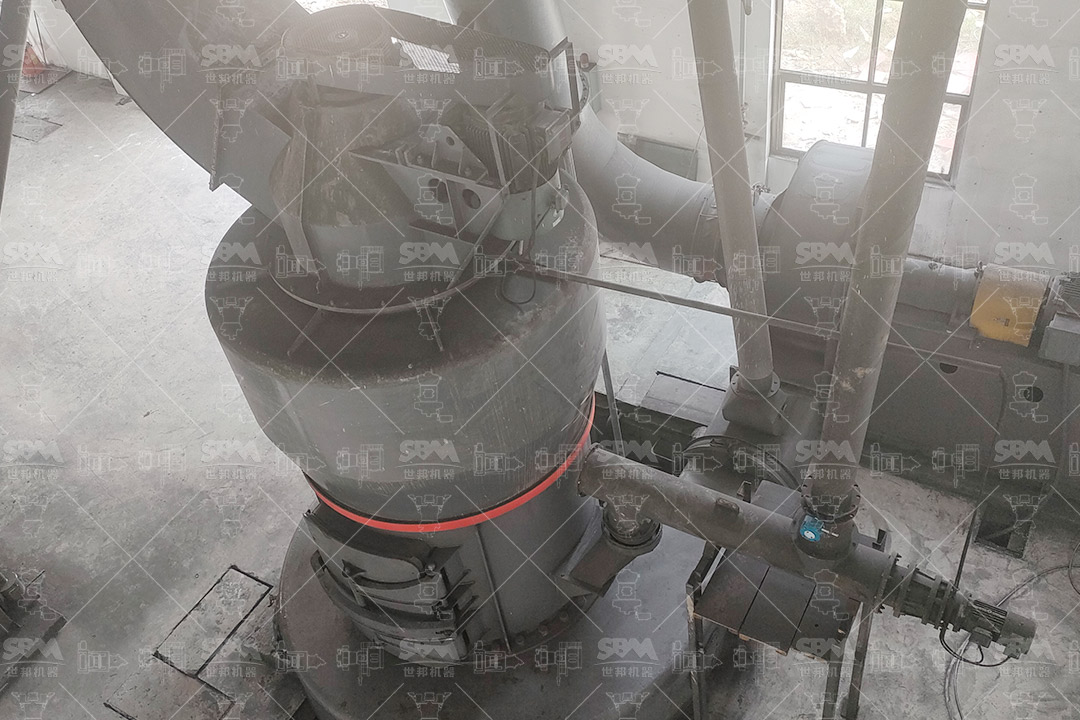

For standard coating formulations where output fineness between 30-325 mesh is sufficient, our MTW Series Trapezium Mill provides an excellent balance of performance, efficiency, and operational economy. This robust grinding system handles feed materials up to 50mm in size and delivers production capacities from 3 to 45 tons per hour, depending on the specific model selected.

The MTW Series incorporates several features particularly advantageous for coating production environments:

Available in multiple configurations including the MTW110 (3-9 ton/h), MTW138Z (6-17 ton/h), and MTW215G (15-45 ton/h), the MTW Series offers coating producers flexible solutions matched to their specific production volumes and quality requirements.

Hammer mills play a crucial role in determining both particle size characteristics and overall product quality in coating production. The selection of appropriate grinding equipment and optimization of operational parameters directly influence key coating properties including color development, film formation, surface characteristics, and application performance.

While traditional hammer mills serve many applications effectively, specialized grinding systems such as our SCM Series Ultrafine Mill and MTW Series Trapezium Mill offer enhanced capabilities specifically tailored to the demanding requirements of modern coating production. By understanding the relationships between milling parameters and product characteristics, coating manufacturers can select equipment that delivers optimal performance for their specific applications while maintaining efficiency and cost-effectiveness.

As coating technologies continue to advance, with increasing demands for finer particles, narrower size distributions, and enhanced performance properties, the role of precision grinding equipment becomes ever more critical. Investing in appropriate milling technology represents a strategic decision that directly impacts product quality, production efficiency, and ultimately, market competitiveness in the coatings industry.