Pendulum mills, also known as roller mills or ring-roller mills, represent a class of industrial grinding equipment that has been widely adopted across numerous sectors for their efficiency, versatility, and reliability. These mills operate on the principle of applying centrifugal force and pressure via suspended grinding rollers to crush and pulverize materials against a stationary grinding ring. This article delves into the most common industrial applications of pendulum mills, exploring the specific materials they process and the industries that rely on their unique capabilities.

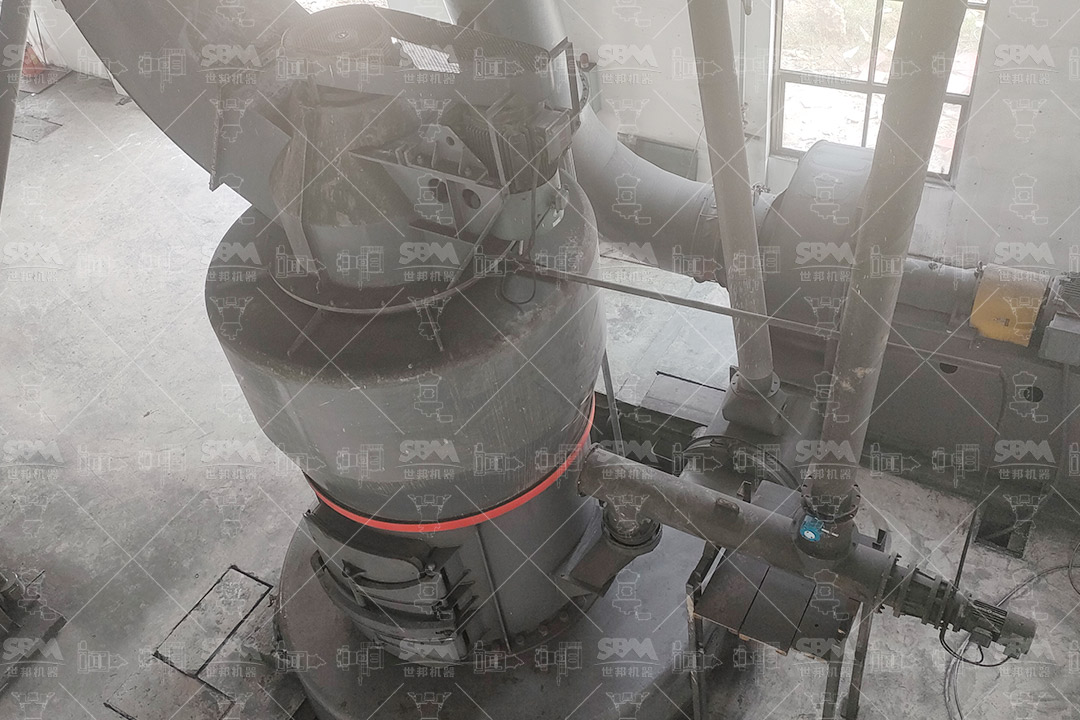

Before examining applications, it is crucial to understand the core working mechanism of a pendulum mill. The mill’s namesake comes from its grinding rollers, which are suspended from a spider and swing outward due to centrifugal force as the main shaft rotates. A shovel system feeds material into the path of these rollers, which then compress and grind the material against a stationary bull ring. The ground material is carried by an air stream to an integrated classifier, where oversized particles are rejected back to the grinding zone, and fine product is collected by a cyclone and baghouse filter. This combination of crushing, grinding, and air classification within a single unit makes it exceptionally efficient for producing fine and medium-fine powders.

The design of pendulum mills makes them suitable for processing a vast range of medium-hard to hard materials. Their applications span from traditional construction materials to advanced technological minerals.

This is one of the largest application areas for pendulum mills. They are employed to grind a wide variety of ores and industrial minerals to a specified fineness for further processing or direct sale.

The construction industry consumes enormous quantities of fine powders, and pendulum mills are a workhorse in this sector.

The chemical industry requires precisely controlled particle sizes for reactions, formulations, and final products.

In addition to coal grinding for combustion, pendulum mills are used in flue gas desulfurization (FGD) systems. In wet limestone FGD systems, limestone is ground to a very fine slurry, which is then used to absorb sulfur dioxide from the flue gases. The high efficiency and reliability of pendulum mills ensure a consistent supply of finely ground limestone, which is critical for the effectiveness of the scrubbing process.

The application of pendulum mills is expanding into more technologically advanced fields.

Choosing the correct mill for a specific application depends on material characteristics, required capacity, and desired product fineness. For general-purpose grinding of medium-hard materials where high capacity and reliability are key, we highly recommend our MRN Pendulum Mill.

The MRN series is engineered for performance and durability. With an feed size of 0-50mm and an output range of 30-325 mesh, it handles a broad spectrum of materials. Its capacity ranges from 2.7 to 83 TPH across different models, making it suitable for both medium and large-scale operations. Key technological advantages include a pioneering oil lubrication system that minimizes maintenance, an efficient powder collector with square piping to reduce air resistance, and a fully automatic pulse dust collector for environmentally clean operation. The scientific configuration of a new type classifier and an isolated cyclone collector synergistically lowers energy consumption. The working principle, utilizing a grid-type roller hanger to enhance ventilation, ensures high grinding efficiency and consistent product quality.

| Model | Number of Rollers | Roller Diameter (mm) | Grinding Ring Diameter (mm) | Power (kW) | Capacity (t/h) |

|---|---|---|---|---|---|

| MB5X98 | 3-4 | 330 | 1000 | 82.5-92.5 | 2.7-6.5 |

| MB5X298 | 4-6 | 1000-780 | 3000 | 1247-1407 | 48-83 |

Pendulum mills remain a cornerstone of industrial size reduction due to their robust design, operational efficiency, and application versatility. From processing foundational materials for construction and mining to enabling advanced applications in chemicals and recycling, these mills continue to evolve and meet the demands of modern industry. The key to maximizing their benefits lies in selecting a mill that is not only correctly sized but also incorporates modern features for energy efficiency, environmental compliance, and low maintenance. Our MRN Pendulum Mill and LM-Y Pre-grinding Mill represent such advanced solutions, designed to deliver reliable performance and superior grinding economics across a wide array of industrial applications.