In mineral processing and powder production industries, grinding mills represent critical assets whose operational availability directly impacts production throughput, product quality, and overall profitability. Unplanned downtime not only disrupts production schedules but also incurs substantial maintenance costs and lost revenue. This comprehensive guide explores proven strategies to minimize grinding mill downtime while maximizing operational efficiency through advanced equipment selection, preventive maintenance protocols, and intelligent operational practices.

Effective downtime reduction begins with a thorough understanding of its primary causes. Common factors contributing to grinding mill interruptions include:

By systematically addressing these failure modes through proper equipment selection and maintenance planning, operations can significantly improve mill availability.

A well-structured preventive maintenance program represents the most effective approach to minimizing unplanned downtime. Key elements include:

| Maintenance Activity | Frequency | Key Inspection Points | Expected Outcome |

|---|---|---|---|

| Daily Visual Inspection | Each Shift | Lubrication levels, unusual noises, vibration patterns | Early problem detection |

| Weekly Component Check | Weekly | Wear part thickness, belt tension, fastener integrity | Prevention of catastrophic failures |

| Monthly Comprehensive Review | Monthly | Bearing condition, alignment, motor performance | Optimization of component life |

| Quarterly Major Inspection | Quarterly | Complete wear part assessment, system calibration | Extended equipment lifespan |

Implementing a condition-based maintenance approach utilizing vibration analysis, thermal imaging, and lubricant analysis can further enhance maintenance effectiveness by identifying developing issues before they cause failures.

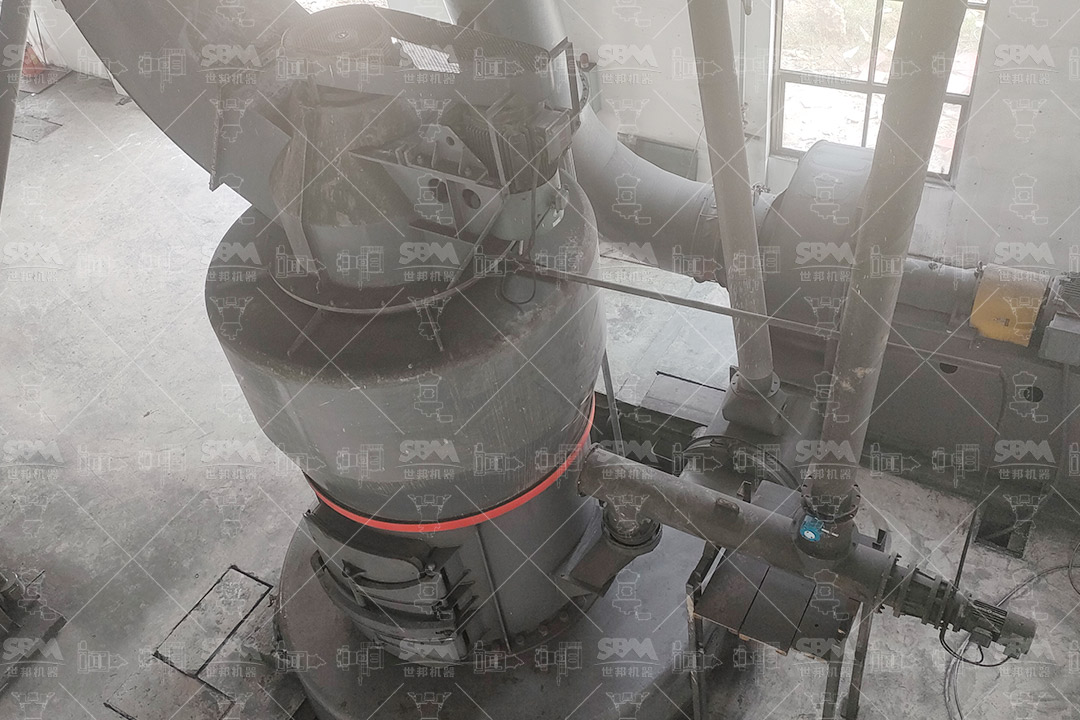

Choosing grinding equipment with robust design features and advanced reliability engineering significantly reduces downtime potential. Modern grinding mills incorporate numerous technological advancements that directly address common failure points:

Durability-Enhanced Components: Equipment featuring special alloy grinding elements with extended service life dramatically reduces replacement frequency. For instance, our SCM Ultrafine Mill incorporates specially hardened roller and ring materials that provide 2-3 times longer service life compared to conventional materials, substantially decreasing maintenance-related interruptions.

Intelligent Lubrication Systems: Advanced mills now incorporate automated lubrication systems that ensure optimal bearing protection while eliminating manual lubrication inconsistencies. The patented internal oil lubrication system in our MTW Series Trapezium Mill represents a significant advancement in this area, providing continuous protection to critical components and virtually eliminating lubrication-related failures.

Modular Component Design: Equipment designed with quick-change wear parts enables significantly reduced replacement downtime. Modular roller assemblies that can be replaced without major disassembly can cut maintenance time by up to 60% compared to conventional designs.

Beyond equipment selection and maintenance, operational practices play a crucial role in maximizing grinding mill performance and availability:

Optimal Feed Material Preparation: Ensuring consistent feed size distribution within equipment specifications prevents overload conditions and uneven wear. Implementing proper pre-crushing and screening operations tailored to your mill’s input requirements (e.g., ≤20mm for the SCM Series, ≤50mm for the MTW Series) ensures stable operation and extended component life.

Precision Process Control: Modern grinding mills benefit tremendously from automated control systems that maintain optimal operating parameters. Our SCM Ultrafine Mill features intelligent control systems with automatic feedback on product fineness, ensuring consistent output quality while preventing conditions that accelerate wear or cause blockages.

Systematic Performance Monitoring: Implementing comprehensive monitoring of key performance indicators including specific energy consumption, throughput rates, and product fineness enables early detection of efficiency degradation before it progresses to equipment failure.

The integration of Industry 4.0 technologies has revolutionized grinding mill maintenance strategies. Implementing IoT sensors for continuous monitoring of vibration, temperature, and acoustic emissions enables true predictive maintenance. Advanced analytics can detect subtle changes in operational patterns that indicate developing issues, allowing maintenance to be scheduled during planned production breaks rather than as emergency interventions.

Remote monitoring capabilities further enhance maintenance efficiency by enabling expert diagnosis without requiring physical presence at the site. This is particularly valuable for operations in remote locations or those with limited access to specialized technical expertise.

Our SCM Ultrafine Mill exemplifies how thoughtful engineering directly addresses downtime reduction challenges. Key reliability-enhancing features include:

These design elements collectively contribute to the SCM Series’ documented 30% reduction in energy consumption and significantly extended maintenance intervals compared to conventional grinding technologies.

An often-overlooked aspect of downtime minimization is strategic spare parts inventory management. Maintaining critical spares based on failure probability and impact analysis ensures that necessary components are available when needed without excessive inventory carrying costs. Key considerations include:

For operations utilizing our MTW Series Trapezium Mill, the combination wear shovel blade design substantially reduces spare parts consumption, while the curved air channel optimization minimizes wear on critical airflow components.

Well-trained operational and maintenance personnel represent the first line of defense against unplanned downtime. Comprehensive training covering proper operating procedures, routine maintenance tasks, and early problem recognition ensures that equipment is operated within design parameters and developing issues are identified promptly.

Maintaining detailed equipment documentation including maintenance histories, operational parameters, and modification records provides invaluable reference material for troubleshooting and optimizing maintenance strategies over the equipment lifecycle.

Reducing grinding mill downtime and improving operational efficiency requires a comprehensive approach encompassing equipment selection, maintenance practices, operational protocols, and technological integration. By implementing the strategies outlined above and selecting equipment with proven reliability features like those incorporated in our SCM Ultrafine Mill and MTW Series Trapezium Mill, operations can achieve significant improvements in availability, productivity, and total cost of ownership.

The most successful operations recognize that downtime reduction is not a single initiative but an ongoing commitment to excellence across equipment, processes, and people. Through continuous improvement in these areas, grinding operations can transform from unpredictable cost centers to reliable, high-efficiency production assets.