Ball mill efficiency is a critical factor in mineral processing and powder production industries, directly impacting operational costs, product quality, and overall profitability. While many factors contribute to ball mill performance, the selection of appropriate grinding media remains one of the most crucial yet often overlooked aspects. This comprehensive guide explores the science behind grinding media selection and how it interacts with various milling technologies to achieve optimal results.

The grinding process in ball mills involves complex interactions between the mill design, material properties, operational parameters, and grinding media characteristics. Understanding these relationships is essential for maximizing efficiency, reducing energy consumption, and achieving the desired product specifications.

Grinding media comes in various materials, shapes, and sizes, each offering distinct advantages for specific applications:

| Media Type | Material Composition | Hardness (HRC) | Density (g/cm³) | Primary Applications |

|---|---|---|---|---|

| Forged Steel Balls | High Carbon Steel | 58-65 | 7.8 | Coarse grinding of hard materials |

| Cast Steel Balls | Chromium Alloy | 58-64 | 7.6-7.8 | General purpose grinding |

| High Chrome Balls | 11-30% Chromium | 58-66 | 7.6-7.8 | Abrasive materials, cement |

| Stainless Steel Balls | 304/316 Stainless | 55-62 | 7.9 | Food, pharmaceutical applications |

| Ceramic Balls | Alumina, Zirconia | 80-90 (Rockwell A) | 3.6-6.0 | Non-contaminating applications |

| Cylpebs | Various Steel Types | 55-65 | 7.6-7.8 | Fine grinding with increased surface area |

The performance of grinding media is determined by several critical properties that must be carefully matched to the specific application:

Hardness and Toughness: These complementary properties determine the media’s resistance to wear and impact. High hardness reduces wear rates but may increase brittleness, while toughness prevents breakage under impact loading. The optimal balance depends on the material being ground and the mill operating conditions.

Density: Higher density media provides greater impact energy per unit volume, making it more efficient for coarse grinding. The density affects the media’s kinetic energy and consequently its grinding efficiency.

Size Distribution: Proper size distribution ensures efficient grinding across different particle size ranges. Larger media excels at breaking coarse particles, while smaller media provides the surface area needed for fine grinding.

Shape and Surface Characteristics: Spherical media offers consistent impact patterns, while cylindrical media (cylpebs) provides more grinding surface area. Surface smoothness affects wear rates and potential contamination.

The properties of the material being ground significantly influence media selection decisions:

Hardness and Abrasiveness: Hard, abrasive materials require media with high hardness and wear resistance. For extremely abrasive materials, high-chrome or specially alloyed media may be necessary to maintain reasonable service life.

Particle Size Distribution: The feed size and desired product size determine the appropriate media size distribution. Coarse feeds require larger media for effective impact breaking, while fine grinding benefits from smaller media with increased surface area.

Moisture Content: Wet grinding typically allows for smaller media sizes due to improved mobility and slurry transport. Dry grinding may require adjustments to media size and mill operating parameters.

Chemical Compatibility: Certain materials may react with specific media types, causing contamination or accelerated wear. In such cases, ceramic or specialized alloy media may be necessary.

The ball mill’s design and operating conditions directly affect media selection:

Mill Speed: The relationship between actual mill speed and critical speed affects the media motion pattern. This influences whether cascading, cataracting, or centrifuging occurs, each requiring different media characteristics.

Mill Dimensions: The length-to-diameter ratio affects residence time and grinding efficiency. Larger diameter mills can accommodate larger media sizes for coarse grinding applications.

Liner Design: The mill liner profile influences the lift characteristics and media trajectory. Different liner designs work best with specific media types and size distributions.

Pulp Density: In wet grinding applications, slurry density affects media mobility and impact energy. Optimal pulp density varies with media size and material characteristics.

Beyond technical performance, economic factors play a crucial role in media selection:

Media Consumption Rates: Higher quality media typically has higher initial costs but may offer lower consumption rates, reducing overall operating costs.

Energy Efficiency: Proper media selection can significantly reduce specific energy consumption, which often represents the largest operational cost in grinding circuits.

Maintenance Requirements: Media that causes excessive liner wear or requires frequent replenishment increases maintenance costs and downtime.

Product Value: For high-value products, media that minimizes contamination may justify higher costs despite similar grinding performance.

Determining the optimal media size involves both theoretical calculations and practical considerations:

Bond’s Formula: The classic approach for initial media size selection considers the feed size, work index, and mill dimensions. While providing a good starting point, this method should be supplemented with operational experience.

Population Balance Models: Advanced modeling techniques simulate the grinding process, accounting for breakage rates, classification effects, and media wear. These models help optimize the media size distribution for specific applications.

Wear Rate Analysis: Regular monitoring of media wear rates provides data for refining the media charge. Abnormal wear patterns can indicate issues with media selection or mill operation.

The total media charge and its distribution within the mill significantly impact performance:

Fill Level Optimization: The optimal media fill level typically ranges from 30% to 45% of mill volume, depending on mill design and operating conditions. Both underfilling and overfilling reduce grinding efficiency.

Size Distribution Strategy: A properly graded charge with multiple media sizes typically outperforms a single-size charge. The distribution should match the particle size distribution in the mill for maximum efficiency.

Replenishment Strategies: Regular addition of make-up media maintains the optimal size distribution and charge volume. The replenishment rate and size should be based on wear rate data.

While proper media selection optimizes ball mill performance, integrating complementary grinding technologies can further enhance overall efficiency. For applications requiring ultra-fine grinding with precise particle size control, our SCM Ultrafine Mill offers exceptional performance with output fineness ranging from 325 to 2500 mesh (D97≤5μm).

The SCM Ultrafine Mill incorporates advanced features that make it particularly suitable for demanding applications:

High-Efficiency Operation: With capacity doubling that of jet mills and energy consumption reduced by 30%, the SCM series represents a significant advancement in fine grinding technology. Its intelligent control system automatically adjusts operational parameters based on real-time feedback of product particle size.

Precision Classification: The vertical turbine classifier ensures accurate particle size cuts with no coarse powder contamination, delivering exceptionally uniform final products. This precision makes it ideal for applications where consistent particle size distribution is critical.

Durable Construction: Specially manufactured roller and ring materials extend service life several times over conventional designs. The bearing-free screw grinding chamber ensures stable operation with minimal maintenance requirements.

Available in multiple configurations from the SCM800 with 0.5-4.5 ton/hour capacity to the high-capacity SCM1680 processing 5.0-25 tons per hour, this technology provides scalable solutions for various production requirements.

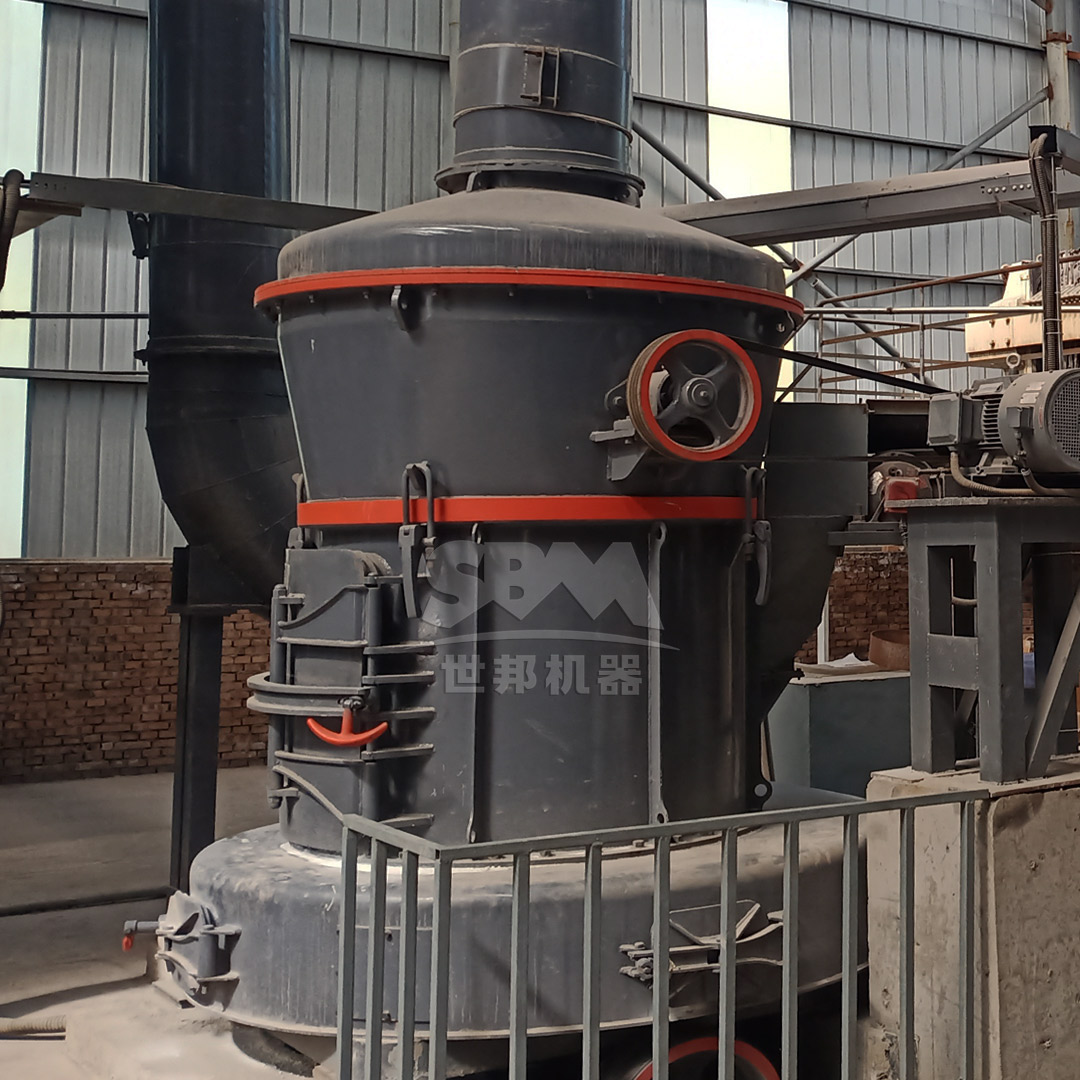

For operations requiring both coarse and fine grinding capabilities, combining ball mills with pre-grinding or finishing mills often yields optimal results. Our LM Series Vertical Roller Mill serves as an excellent pre-grinding solution, handling feed sizes up to 50mm and producing intermediate products in the 30-325 mesh range.

The LM series offers several advantages for integrated grinding circuits:

Compact Design: Integrated crushing, grinding, and separation functions reduce footprint requirements by 50%, while the ability for outdoor installation cuts infrastructure costs by 40%.

Reduced Operating Costs: The non-contact design between grinding rollers and the disc extends wear part life up to three times, while energy consumption is 30-40% lower compared to traditional ball mill systems.

Intelligent Control: Expert-level automatic control systems support remote/local switching and real-time monitoring of operational parameters, minimizing manual intervention.

With models ranging from the LM130K handling 10-28 tons per hour to the massive LM370N with 90-110 ton/hour capacity for slag grinding, the LM series provides comprehensive solutions for diverse industrial applications.

Continuous monitoring of key performance indicators enables ongoing optimization of grinding media selection and mill operation:

| Performance Metric | Target Range | Measurement Frequency | Corrective Actions |

|---|---|---|---|

| Specific Energy Consumption | Industry benchmark ±10% | Continuous | Adjust media size, mill speed, or feed rate |

| Media Consumption Rate | <0.8 kg/ton for hard ores | Weekly | Evaluate media quality and size distribution |

| Product Size Distribution | Within specification limits | 4-8 hour intervals | Modify media charge or classifier settings |

| Mill Sound Level | Consistent with optimal charge | Continuous | Adjust media charge volume |

| Power Draw | 80-95% of motor rating | Continuous | Optimize media fill level and composition |

Modern grinding operations benefit from advanced monitoring technologies that provide real-time data for optimization:

Acoustic Analysis: Mill sound monitoring can detect changes in charge volume and composition, allowing proactive adjustments before performance degrades.

Vibration Analysis: Monitoring mill vibration patterns helps identify issues with media distribution, liner condition, or mechanical problems.

Online Particle Size Analysis: Real-time measurement of product size distribution enables immediate adjustments to maintain product quality.

Wear Monitoring Systems: Advanced sensors track media and liner wear rates, optimizing replacement schedules and media replenishment strategies.

Selecting the right grinding media is a complex but essential aspect of optimizing ball mill efficiency. This decision requires careful consideration of material properties, mill design, operational parameters, and economic factors. By following a systematic approach to media selection and integrating complementary grinding technologies where appropriate, operations can achieve significant improvements in energy efficiency, product quality, and overall profitability.

The ongoing optimization of grinding media, supported by advanced monitoring technologies and data analysis, ensures that ball mill operations remain competitive in an increasingly challenging industrial landscape. Whether using traditional steel media or exploring advanced ceramic alternatives, the principles outlined in this guide provide a foundation for making informed decisions that maximize grinding efficiency and minimize operational costs.