January 02, 2026

Introduction

The processing of manganese ore into fine powder is a critical step in numerous industrial applications, including steel production, battery manufacturing (particularly for lithium-ion batteries), welding electrode production, and chemical synthesis. The quality, consistency, and fineness of the manganese powder directly influence the performance and cost-efficiency of the final products. Achieving the desired particle size distribution (PSD) while maintaining high throughput and low operational costs presents significant technical challenges. This article delves into the complexities of manganese ore grinding, explores the key technological considerations, and highlights advanced equipment solutions essential for modern, efficient production lines.

Characteristics and Grinding Challenges of Manganese Ore

Manganese ores vary in composition, primarily as oxides (like pyrolusite, MnO2) or carbonates (rhodochrosite, MnCO3). Their grinding behavior is influenced by several factors:

- Hardness and Abrasiveness: Manganese minerals often have moderate to high hardness (Mohs scale 3-6). This abrasiveness leads to high wear on grinding media and mill liners, increasing maintenance costs and contamination risks from worn metal.

- Moisture Content: Run-of-mine ore can contain moisture, which may cause clogging in fine grinding circuits, especially in dry milling processes, requiring pre-drying stages.

- Target Fineness Requirements: End-use applications demand specific fineness. For instance, battery-grade manganese requires ultra-fine powders (often D97 < 10μm), while ferroalloy production may use coarser grinds. Achieving and consistently maintaining these tight specifications is paramount.

- Contamination Control: For high-purity applications, minimizing iron or other metallic contamination from the grinding process itself is crucial.

Overcoming these challenges necessitates grinding equipment that is not only robust and wear-resistant but also offers precise classification and energy-efficient operation.

Key Technological Stages in Manganese Powder Production

A typical production line involves several stages:

- Primary Crushing: Large ore lumps are reduced to a manageable size (typically below 50mm) using jaw or gyratory crushers.

- Secondary Crushing & Pre-Grinding: Further size reduction to feed size suitable for fine grinding mills (often below 20-30mm). Hammer mills or cone crushers are commonly used.

- Fine & Ultra-Fine Grinding: The core stage where the ore is ground to the target fineness. This stage consumes the most energy and determines final product quality.

- Classification Integrated or separate classifiers (e.g., dynamic air classifiers) separate fine product from coarse material, which is recirculated for further grinding.

- Collection & Dedusting: Efficient cyclone separators and baghouse filter systems collect the final powder and ensure environmental compliance.

Critical Equipment for Grinding Manganese Ore

Selecting the right grinding mill is the most decisive factor for plant economics and product quality. Different mill types offer distinct advantages based on capacity, target fineness, and ore characteristics.

1. Ball Mills

A traditional and versatile choice, ball mills operate on the principle of impact and attrition as grinding media (steel balls) cascade inside a rotating cylinder. They are suitable for both wet and dry grinding and can handle a wide range of feed sizes.

- Advantages: High reliability, simple operation, capable of producing fine to moderately fine powder (typically down to 45μm/325 mesh).

- Limitations for Manganese: Relatively high energy consumption, significant wear of balls and liners leading to iron contamination, and limited efficiency in the ultra-fine range (< 10μm). They are often better suited for the pre-grinding stage or applications where extreme fineness is not required.

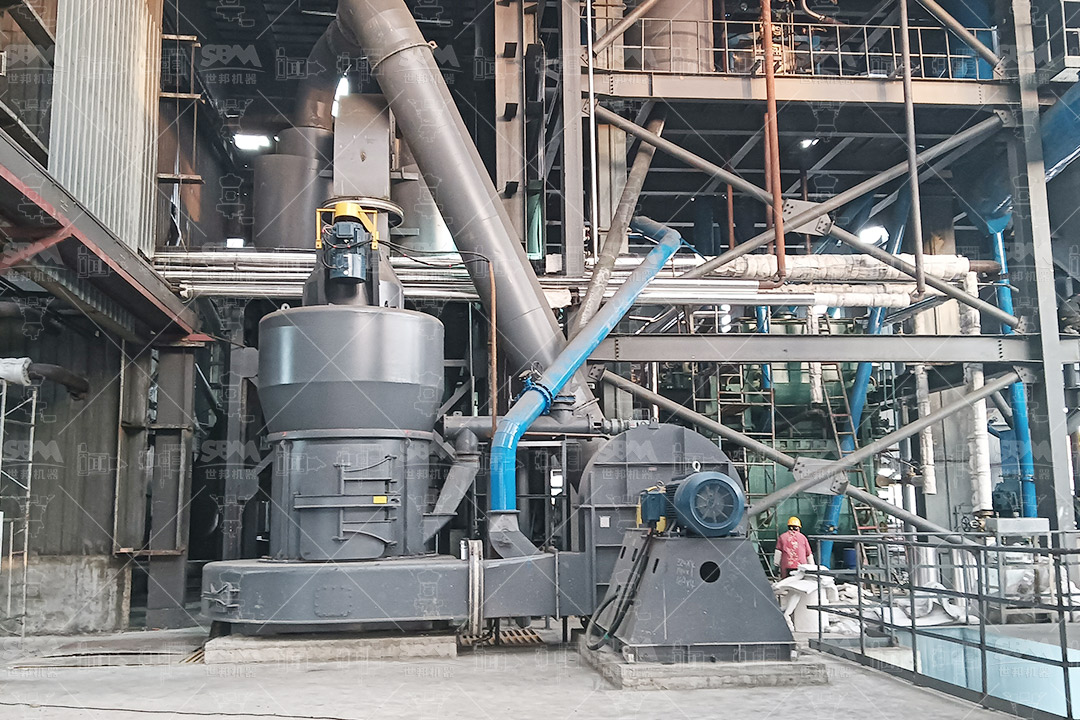

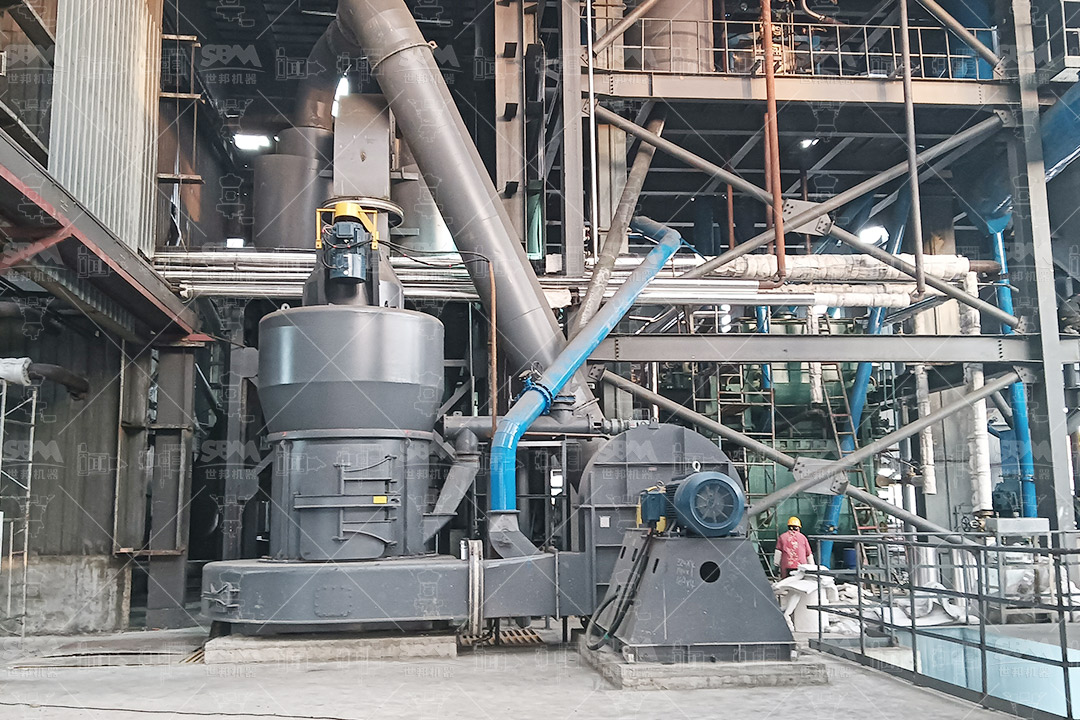

2. Vertical Roller Mills (VRM)

VRMs have become a industry standard for efficient mineral grinding. Material is fed onto a rotating grinding table and crushed under rollers pressed against the table. Ground material is transported by air to an integrated classifier.

- Advantages: Excellent energy efficiency (30-50% less than ball mills), lower wear rates due to the bed grinding principle, compact design, and integrated drying capability using hot gas.

- Application for Manganese: Highly effective for medium to fine grinding of manganese ore (output range typically 30-325 mesh/45-600μm). Their ability to handle moderately abrasive materials and provide stable product quality makes them a strong candidate for large-scale production lines.

3. Raymond Mills (or Pendulum Roller Mills)

These mills use spring-loaded rollers that rotate against a stationary grinding ring. The material is fed into the grinding zone and crushed by the roller’s rolling and squeezing action.

- Advantages: Proven technology, relatively low capital cost, good for producing powders in the 30-325 mesh range.

- Limitations: May have higher wear on grinding parts compared to VRMs for very abrasive materials, and achieving ultra-fine fineness can be challenging and inefficient.

4. Ultra-Fine Grinding Mills

For applications demanding micron and sub-micron sized powders, specialized ultra-fine mills are essential. These include stirred media mills, jet mills, and advanced ring-roller mills designed for high fineness.

- Advantages: Capable of producing powders from 325 mesh down to 5μm or even finer with a narrow PSD.

- Key Features: They incorporate high-precision air classifiers, often use ceramic or other specialized wear materials to minimize contamination, and are engineered for precise control over grinding energy.

Recommended Solution: SCM Series Ultrafine Mill for High-Quality Manganese Powder

For producers targeting the high-value markets requiring ultra-fine manganese powder—such as advanced battery materials or high-performance ceramics—conventional grinding mills often fall short in terms of efficiency, fineness control, and contamination management. In this context, our SCM Series Ultrafine Mill stands out as an optimal technological solution.

The SCM Mill is engineered specifically for the demanding task of producing fine and ultra-fine powders from hard and abrasive minerals like manganese ore. Its design incorporates several breakthrough features that directly address the challenges outlined earlier:

- Superior Fineness and Output: The mill consistently produces powder in the range of 325 to 2500 mesh (D97 ≤ 5μm), meeting the strictest specifications for advanced applications. With a capacity ranging from 0.5 to 25 tons per hour depending on the model, it offers scalability from pilot plants to full-scale production.

- Exceptional Energy Efficiency By utilizing a layered grinding principle with multiple grinding rings and rollers, it achieves a grinding efficiency far higher than traditional jet mills or ball mills. Operational data shows it can offer twice the capacity of a jet mill while reducing energy consumption by approximately 30%.

- High-Precision Classification System The integrated vertical turbine classifier is a key component. It ensures precise cut-point control, resulting in a uniform product with no coarse particle contamination. The fineness can be adjusted instantly and reliably during operation.

- Enhanced Durability for Abrasive Materials Recognizing the wear potential of manganese ore, critical grinding components like the roller and grinding ring are manufactured from special wear-resistant alloys, extending service life several times over compared to standard materials. The innovative bearing-less screw design in the grinding chamber further enhances mechanical stability and reduces failure points.

- Comprehensive Environmental Protection The system is designed as a negative-pressure, fully sealed operation. It is equipped with a high-efficiency pulse dust collector that exceeds international emission standards, ensuring a clean workshop. Furthermore, soundproofing measures keep operational noise below 75dB.

| Model |

Capacity (ton/h) |

Main Motor Power (kW) |

Feed Size (mm) |

Final Fineness (mesh) |

| SCM800 |

0.5 – 4.5 |

75 |

≤20 |

325-2500 |

| SCM900 |

0.8 – 6.5 |

90 |

≤20 |

325-2500 |

| SCM1000 |

1.0 – 8.5 |

132 |

≤20 |

325-2500 |

| SCM1250 |

2.5 – 14 |

185 |

≤20 |

325-2500 |

| SCM1680 |

5.0 – 25 |

315 |

≤20 |

325-2500 |

For projects requiring high-volume production of fine manganese powder (e.g., for ferroalloys or standard chemical grades) where the ultra-fine range is not the primary target, our MTW Series European Trapezium Mill presents an excellent balance of high throughput, robustness, and cost-effectiveness. With a capacity range of 3 to 45 tons per hour and the ability to produce powder from 30 to 325 mesh, the MTW series is renowned for its durable construction—featuring curved air ducts, wear-resistant shovel blades, and an efficient overall gear drive—making it a workhorse for demanding mineral grinding applications.

System Integration and Best Practices

Implementing a successful manganese powder plant goes beyond selecting the right mill. A holistic system approach is necessary:

- Feed Preparation: Ensure consistent feed size and moisture content to the grinding mill. Pre-drying and efficient pre-crushing are vital.

- Automation and Control: Modern mills like the SCM series feature intelligent control systems that automatically adjust operational parameters based on feedback, ensuring consistent product quality and optimizing energy use.

- Material Handling and Packaging: Use enclosed conveyors, silos, and automated bagging/palletizing systems to prevent product degradation and ensure dust-free handling of the fine powder.

- Maintenance Strategy Adopt a predictive maintenance schedule focused on wear parts monitoring (rollers, rings, classifier blades) to plan downtime and avoid unplanned production stops.

Conclusion

The transition from raw manganese ore to a high-value, specification-grade powder is a technologically intensive process. The choice of grinding equipment is the cornerstone of this transformation, impacting product quality, operational cost, and plant profitability. While several mill types can perform the task, the specific requirements for fineness, purity, and efficiency increasingly point towards advanced, integrated solutions like ultra-fine grinding systems.

Our SCM Series Ultrafine Mill, with its unparalleled combination of fine grinding capability, energy efficiency, durability against abrasive materials, and environmental performance, is specifically engineered to meet the future demands of the manganese processing industry. By partnering with a technology provider that understands these complex material challenges, producers can build a competitive edge, ensuring their manganese powder meets the evolving standards of tomorrow’s high-tech applications.