Heavy calcium carbonate (GCC), a crucial industrial mineral derived from natural calcite, limestone, or marble, is a cornerstone material for numerous industries, including plastics, paints, coatings, paper, rubber, and construction. The selection of optimal processing equipment is paramount, directly influencing product quality, production efficiency, operational costs, and overall plant profitability. This comprehensive guide will navigate you through the critical factors and technical considerations essential for making an informed investment in your GCC processing line.

Choosing the right equipment is not a one-size-fits-all decision. It requires a holistic analysis of your specific operational goals and constraints.

The most decisive factor is your required final product specification.

Your plant’s throughput requirement, both current and projected future expansion, dictates the scale and model of the equipment. It’s crucial to match the mill’s capacity to your upstream crushing and downstream packaging capabilities.

Grinding is an energy-intensive process. The specific energy consumption (kWh/ton) of the mill is a major contributor to the operational expenditure (OPEX). Modern, efficient mills can offer savings of 30-50% compared to older technologies like traditional ball mills.

Consider not only the equipment cost (CAPEX) but also the required building space, foundation strength, and auxiliary systems (dust collection, air classifiers, conveying). Integrated systems can significantly reduce the plant footprint.

Downtime is costly. Evaluate the accessibility of wear parts (rollers, rings, liners), their expected service life, and the complexity of replacement procedures. Equipment with quick-change systems and durable materials offers better long-term value.

Modern plants must adhere to strict environmental standards. Key considerations include:

Different grinding technologies are suited for different fineness ranges and production scales. The following table provides a high-level comparison.

| Equipment Type | Typical Output Fineness | Typical Capacity Range | Key Advantages | Primary Considerations |

|---|---|---|---|---|

| Ball Mill / Rod Mill | 0.074 – 0.8mm (200 – 20 mesh) | Wide (0.65 – 450 TPH) | Proven technology, reliable, suitable for wet/dry grinding. | High energy consumption, noisy, broad PSD, potential overgrinding. |

| Raymond Mill (Roller Mill) | 45 – 325 mesh (0.038mm) | Medium (3 – 45 TPH) | Stable operation, good for medium-fine powder, lower OPEX than ball mills. | Limited to fine (not ultra-fine) range, mechanical complexity. |

| Vertical Roller Mill (VRM) | 30 – 325 mesh (up to 600 mesh) | Large (3 – 250 TPH) | High efficiency, integrated drying/grinding/classification, low energy use. | High initial investment, requires skilled maintenance. |

| Ultrafine Mill | 325 – 2500 mesh (5μm) | Medium-Fine (0.5 – 25 TPH) | Produces ultra-fine and nano powders, precise classification, good particle shape. | Higher specific energy for ultra-fine grinding, sensitive to feed moisture. |

Based on your target product specifications, here is a deeper dive into the most suitable technologies.

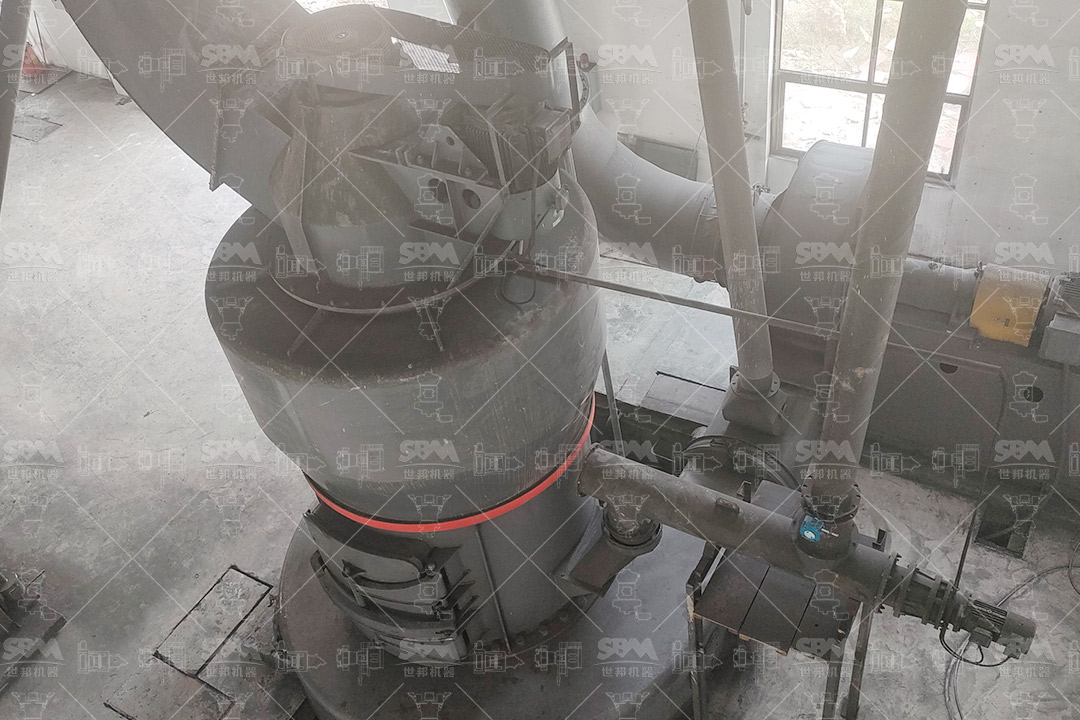

If your plant targets the high-volume markets like paper filling, plastics, or construction materials with fineness between 30 and 325 mesh, the MTW Series European Trapezium Mill represents an excellent choice. This advanced iteration of the traditional Raymond mill incorporates significant technological improvements.

Its curved shovel blade design and wear-resistant volute structure drastically reduce maintenance costs and downtime. The integral bevel gear transmission achieves up to 98% efficiency, translating directly to lower energy consumption per ton of output. With capacities ranging from 3 to 45 tons per hour and the ability to handle feed sizes up to 50mm, it is a robust and efficient workhorse for large-scale fine GCC production. The optimized arc air duct and high-precision classifier ensure a consistent and controllable product fineness.

For producers serving the high-end markets of masterbatch, high-quality paints, sealants, or pharmaceuticals, where ultra-fine particle size and narrow distribution are critical, an ultrafine grinding system is mandatory. The SCM Series Ultrafine Mill is engineered specifically for this demanding application.

This mill excels in producing powders from 325 to 2500 mesh (45-5μm). Its core advantage lies in the high-precision vertical turbine classifier, which ensures sharp particle size cuts and eliminates coarse powder contamination, resulting in a uniform and high-quality product. Despite its ultra-fine capability, it is designed for efficiency, offering a capacity that can be twice that of some jet mills while consuming approximately 30% less energy. Features like special material rollers and rings, a shaftless screw grinding chamber, and a comprehensive pulse dust collection system make it a durable, stable, and environmentally compliant solution for premium GCC production.

Selecting the ideal heavy calcium carbonate processing equipment is a strategic decision that requires balancing technical requirements, economic factors, and long-term operational goals. There is no universal “best” machine, only the best machine for your specific application. By meticulously defining your product needs, thoroughly understanding the capabilities of different grinding technologies like the high-capacity MTW Series Mill for fine grades or the precision-focused SCM Series Ultrafine Mill for premium markets, and rigorously evaluating proposals based on total lifecycle cost, you can invest in a processing line that maximizes your plant’s productivity, quality, and profitability for years to come. Partnering with an experienced supplier who offers comprehensive testing and support is the final key to a successful project.