The production of high-quality putty powder is a cornerstone of the modern construction and building materials industry. As a key ingredient, putty powder demands exceptional fineness, uniformity, and whiteness, all of which are directly influenced by the quality of its primary raw material: ground limestone. Selecting the right grinding equipment is therefore not merely a procurement decision but a strategic choice that determines product quality, production efficiency, and overall operational profitability. This article provides a comprehensive analysis of limestone grinding for putty powder production, detailing the process flow and equipment selection, with a focus on recommending optimal solutions for various production scales.

A complete putty powder production line is an integrated system that transforms raw limestone into a fine, consistent powder ready for packaging. The typical process involves several key stages:

Large limestone blocks from the quarry are first subjected to primary crushing using equipment like jaw crushers or hammer mills to reduce them to a manageable size (typically below 50mm). This step is crucial for ensuring a consistent feed to the grinding mill and optimizing its performance.

This is the core of the production line. The pre-crushed limestone is fed into a grinding mill where it is pulverized to the required fineness (usually between 200-325 mesh for standard putty). An integrated or separate classifier ensures that only particles meeting the target size are collected as finished product, while oversized particles are returned for further grinding. This closed-circuit system guarantees precise particle size control.

The fine powder produced by the mill is carried by an airflow system to a high-efficiency cyclone collector and a pulse-jet bag filter. These systems separate the powder from the air, achieving collection efficiencies exceeding 99.9%. The collected powder is then conveyed via screw conveyors or pneumatic systems to storage silos.

The finished limestone powder is stored in large silos to ensure a buffer for continuous production. It is then automatically weighed and packaged into bags of various sizes (e.g., 20kg, 25kg, or 1-ton big bags) for distribution.

The heart of the line is the grinding mill. Different types of mills offer varying advantages in terms of output fineness, capacity, energy consumption, and operational costs. For putty powder production, the following mills are most commonly considered:

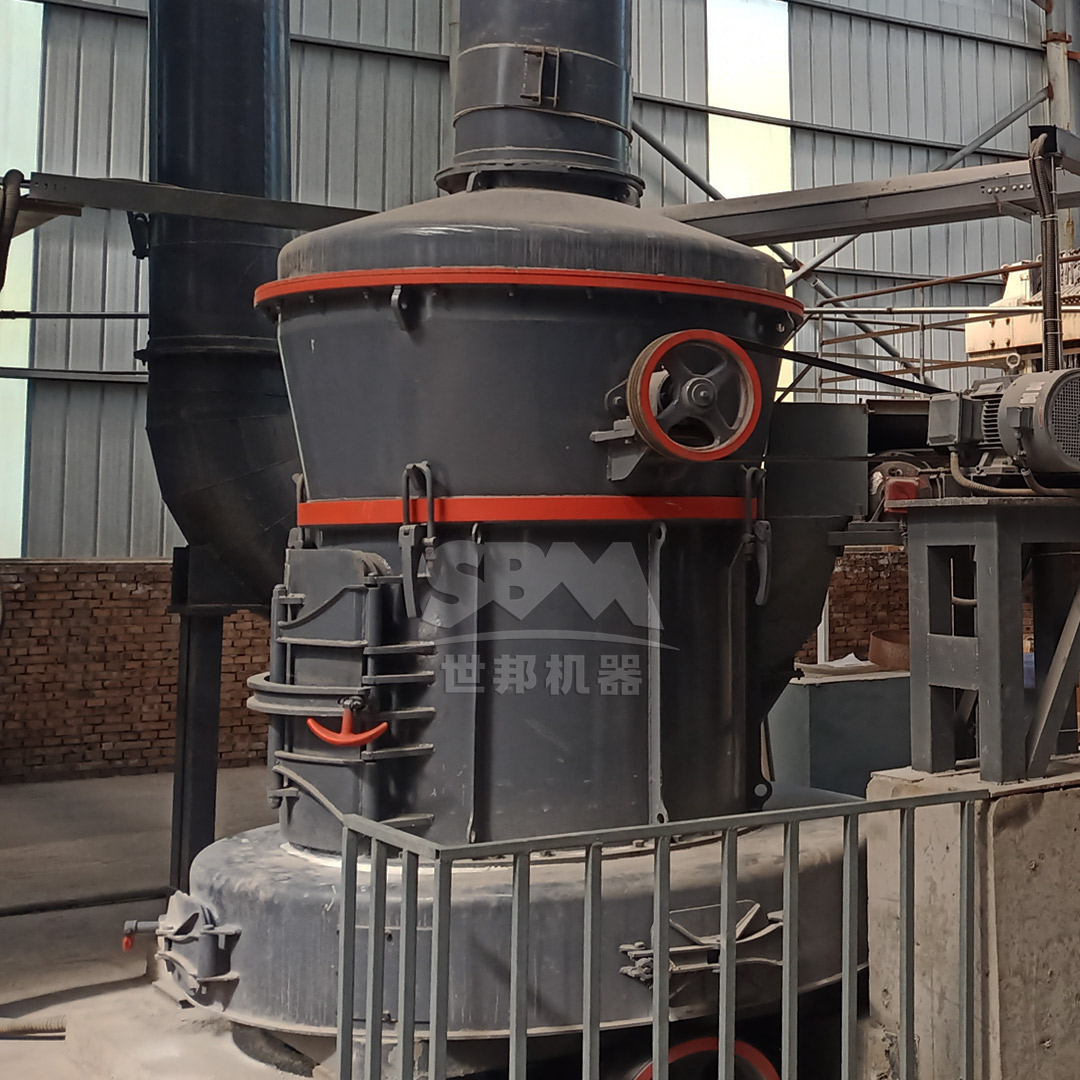

Ideal for medium to large-scale production requiring fineness between 30-325 mesh. Its bevel gear integral transmission and curved air duct design offer high transmission efficiency and low energy loss, making it a robust and reliable workhorse for standard putty powder fineness.

This mill represents a significant technological advancement, integrating crushing, grinding, drying, and classifying into a single unit. It is renowned for its low energy consumption (30-40% lower than traditional ball mills) and small footprint. Its ability to handle moist materials and its excellent drying capability make it highly versatile.

For producers aiming for premium-grade putty powder or seeking to add value through ultra-fine fillers (325-2500 mesh), the SCM Ultrafine Mill is the optimal choice. It excels in producing superfine powders with high uniformity and whiteness, which can enhance the smoothness and bonding properties of the final putty product.

Based on your production goals and scale, we recommend the following equipment configurations:

| Production Scale | Target Fineness | Recommended Mill | Key Advantages |

|---|---|---|---|

| Medium to Large (10-45 TPH) | 200-325 Mesh | MTW Series European Trapezium Mill | High capacity, stable operation, low wear cost, perfect for standard putty powder bulk production. |

| Large Scale, Integrated (15-250 TPH) | 30-325 Mesh | LM Series Vertical Roller Mill | Extremely low energy consumption, integrated drying/grinding, minimal footprint, ideal for greenfield projects. |

| Premium / High-Value Production (0.5-25 TPH) | 325-2500 Mesh (Ultrafine) | SCM Series Ultrafine Mill | Produces superior fineness and whiteness, high classification precision, energy-efficient, enhances final product quality. |

For manufacturers focusing on high-end markets, the SCM Series Ultrafine Mill is a standout solution. Its core strength lies in producing limestone powder with exceptional fineness (up to 2500 mesh) and narrow particle size distribution. The vertical turbine classifier ensures no coarse powder is mixed into the final product, guaranteeing the smooth application and excellent adhesion of the putty. Furthermore, its high-efficiency design offers capacity twice that of jet mills while consuming 30% less energy. The wear parts, made from special materials, significantly extend service life and reduce maintenance downtime. For a production line aiming for superior quality putty powder, the SCM series provides an unbeatable combination of precision, efficiency, and reliability.

When the priority is reliable, high-volume output of standard fineness putty powder, the MTW Series European Trapezium Mill is the proven choice. Its patented technology, including the anti-wear shovel design and optimized arc air duct, directly translates to lower operating costs and higher availability. The integral bevel gear drive achieves a remarkable 98% transmission efficiency, saving energy and space. Models like the MTW215G can handle capacities up to 45 tons per hour, making it the backbone of large-scale putty powder manufacturing plants worldwide. Its durability and ease of maintenance ensure continuous production with minimal interruptions.

A successful plant relies on more than just the mill. Key auxiliary systems include:

Investing in a putty powder production line is a significant decision that requires careful technical evaluation. The choice of grinding equipment—whether the high-capacity MTW Series, the efficient and integrated LM Series, or the precision-focused SCM Ultrafine Mill—will define your product’s market position and operational efficiency for years to come. By understanding the complete process flow and matching the right mill technology to your specific production goals regarding scale, fineness, and quality, you can build a competitive, profitable, and sustainable operation in the dynamic building materials industry.