The rubber manufacturing industry is a cornerstone of modern technology, producing materials essential for everything from automotive tires and industrial belts to medical devices and consumer goods. A critical factor in achieving the desired properties in rubber products—such as tensile strength, abrasion resistance, tear resistance, and cost-effectiveness—is the use of functional fillers and additives. Among these, finely ground calcium carbonate derived from marble has emerged as a premier additive. It acts not only as a cost-effective extender but also as a performance enhancer, improving processing characteristics, dimensional stability, and surface finish. The efficacy of marble powder in rubber compounding is directly tied to its particle size distribution, purity, and morphology. This guide delves into the specialized equipment required to transform raw marble into the high-quality, ultra-fine powders indispensable for advanced rubber product manufacturing.

In rubber technology, the particle size of an additive like marble powder is not a mere specification; it is a determinant of final product performance. Coarse particles (above 45μm or 325 mesh) can act as stress concentrators, leading to premature failure under dynamic loads, reducing tensile strength, and causing poor surface finish. Conversely, ultra-fine particles (below 10μm) offer a vastly increased surface area, allowing for superior dispersion within the rubber matrix. This results in:

Therefore, selecting the right comminution (size reduction) technology is paramount to producing marble powder that meets the stringent requirements of the rubber industry.

| Target Application in Rubber | Recommended Particle Size (Marble Powder) | Key Benefit |

|---|---|---|

| General Extrusion/Calendering | 45-75μm (200-325 mesh) | Good balance of cost, processability, and reinforcement |

| High-Performance Mechanical Goods (Belts, Seals) | 10-45μm (325-1250 mesh) | Enhanced tensile strength, modulus, and fatigue resistance |

| Premium Surface-Critical Products | <10μm (>1250 mesh) | Excellent surface finish, high transparency in some compounds |

The transformation of quarried marble blocks into rubber-grade powder involves a multi-stage process, each requiring specialized equipment.

Stage 1: Primary Crushing

Large marble blocks are reduced to manageable sizes (typically <50mm) using jaw crushers or impact crushers. This stage focuses on high throughput and rugged reliability.

Stage 2: Secondary Grinding & Classification

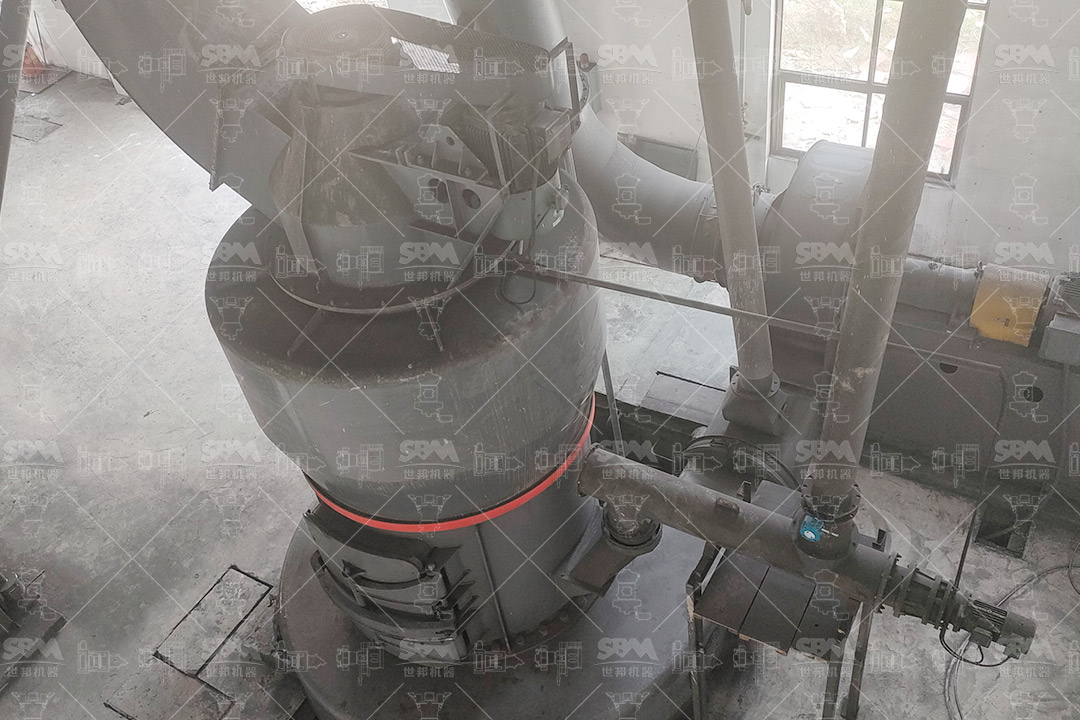

This is the heart of the production line, where the crushed marble is ground to the target fineness. The choice of grinding mill depends entirely on the desired output size and capacity. For rubber-grade powders ranging from coarse fillers to ultra-fine reinforcements, two dominant technologies are employed: Vertical Roller Mills (VRM) for medium-fine ranges and Ultrafine Mills for the finest specifications.

Stage 3: Collection & Packaging

The ground powder is separated from the conveying air stream using high-efficiency cyclone collectors and baghouse dust collectors (like pulse jet filters). The collected powder is then conveyed to silos for bulk storage or to automated bagging machines.

The grinding mill is the most critical capital investment in a marble powder plant. Here’s a comparative analysis of the most suitable technologies.

A. For High-Capacity, Medium-Fine Production (30-325 mesh / 600-45μm)

When the production goal is high volumes of powder in the 100-325 mesh range for general rubber compounding, the MTW Series European Trapezium Mill represents an optimal solution. Its design is engineered for efficiency and durability in non-metallic mineral processing.

| Model Example (MTW Series) | Capacity (t/h)* | Output Fineness | Main Power (kW) | Suitability for Rubber |

|---|---|---|---|---|

| MTW175G | 9.5 – 25 | 30-325 mesh | 160 | Ideal for large-scale production of general-purpose filler. |

| MTW215G | 15 – 45 | 30-325 mesh | 280 | For mega-plants supplying the tire and industrial rubber sectors. |

*Capacity varies with material hardness and product fineness.

B. For Premium, Ultra-Fine Production (325-2500 mesh / 45-5μm)

To produce the ultra-fine and coated marble powders required for high-performance rubber products, a different level of technology is needed. The SCM Series Ultrafine Mill is specifically designed for this demanding application.

| Model Example (SCM Series) | Capacity (t/h)* | Output Fineness | Main Power (kW) | Suitability for Rubber |

|---|---|---|---|---|

| SCM1000 | 1.0 – 8.5 | 325-2500 mesh | 132 | Perfect for producing high-performance filler for automotive and technical rubber goods. |

| SCM1680 | 5.0 – 25 | 325-2500 mesh | 315 | For dedicated large-scale production of ultra-fine and surface-modified marble powder. |

Investing in the right mill is only part of the equation. A successful marble powder plant for rubber additives requires holistic system integration.

Feedstock Consistency: Ensure a consistent feed size and moisture content to the grinding mill. Pre-drying may be necessary if moisture exceeds 1-2%.

Material Handling: Implement enclosed conveyor systems (screw conveyors, bucket elevators) and storage silos to prevent contamination and dust emission.

Classification & Collection: Pair the grinding mill with the correctly sized cyclone and baghouse filter. For ultra-fine powders, consider adding a secondary high-efficiency air classifier for even tighter particle size control.

Automation: Modern mills like the SCM and MTW series come with PLC-based control systems. Utilize these for automated start-up/shutdown sequences, real-time monitoring of key parameters (motor load, temperature, pressure), and feedback loops to maintain consistent product fineness.

The production of marble additives for the rubber industry is a precision engineering task. The choice between a high-capacity mill like the MTW European Trapezium Mill for general-purpose fillers and a specialized SCM Ultrafine Mill for high-performance reinforcements will define your product portfolio and market competitiveness. By understanding the particle size requirements of your target rubber applications and investing in the appropriate, technologically advanced grinding and classification equipment, producers can ensure a consistent, high-quality supply of marble powder that meets the evolving demands of the global rubber manufacturing sector. A focus on system integration, automation, and environmental controls will further guarantee operational efficiency, product purity, and long-term profitability.