The production of high-quality cement-grade gypsum powder is a critical process in modern cement manufacturing, serving as a vital set regulator to control the setting time of cement. An efficient and reliable production line is paramount to ensure consistent product quality, optimal energy consumption, and environmental compliance. This article delves into the core processes and essential equipment required for a state-of-the-art gypsum powder production line, highlighting technological advancements that drive operational excellence.

The transformation of raw gypsum rock into fine, cement-grade powder involves a series of interconnected stages, each demanding specific machinery for optimal performance.

Raw gypsum ore, typically with a feed size up to 400-500mm, is first subjected to primary crushing. Jaw crushers or impact crushers are commonly employed to reduce the material to a manageable size (generally below 50mm) for subsequent grinding. Efficient pre-crushing is crucial for reducing the load on the main grinding mill and improving overall system throughput.

This is the most critical phase where gypsum is simultaneously dried (if necessary, to remove free moisture) and ground to the required fineness. The choice of grinding equipment directly impacts product quality, energy efficiency, and production cost. For cement-grade gypsum, the target fineness usually ranges from 30 mesh (600μm) to 200 mesh (75μm), depending on specific cement formulation requirements.

Post-grinding, an integrated or separate classifier (such as a dynamic separator or cyclone) separates the fine product from oversized particles. The qualified fine powder is then collected by high-efficiency bag filters or electrostatic precipitators, ensuring minimal dust emission and high product recovery.

The finished gypsum powder is conveyed to storage silos. Automated packing systems or bulk loading stations prepare the product for dispatch to cement plants.

Selecting the right grinding mill is the single most important decision in designing a gypsum powder line. Different mills offer varying benefits in terms of capacity, fineness control, and energy consumption.

| Mill Type | Typical Output Fineness | Key Advantages | Considerations for Gypsum |

|---|---|---|---|

| Ball Mill | 0.074-0.8mm (200-20 mesh) | Robust, simple operation, wide capacity range. | Higher energy consumption, less precise particle size control compared to vertical mills. |

| Raymond Mill (MTM/MTW Series) | 45-325 mesh (600-45μm) | Well-established technology, good for medium-fine powder, lower capital cost. | May require pre-drying for moist gypsum; grinding roller wear is a factor. |

| Vertical Roller Mill (LM Series) | 30-325 mesh (600-45μm) | High grinding efficiency, integrated drying, lower energy use, compact footprint. | Ideal for large-scale production of cement-grade gypsum with moisture. |

| Ultrafine Mill (SCM Series) | 325-2500 mesh (45-5μm) | Produces superfine powder, high-precision classification. | For specialized applications requiring ultra-high fineness, not typical for standard cement-grade. |

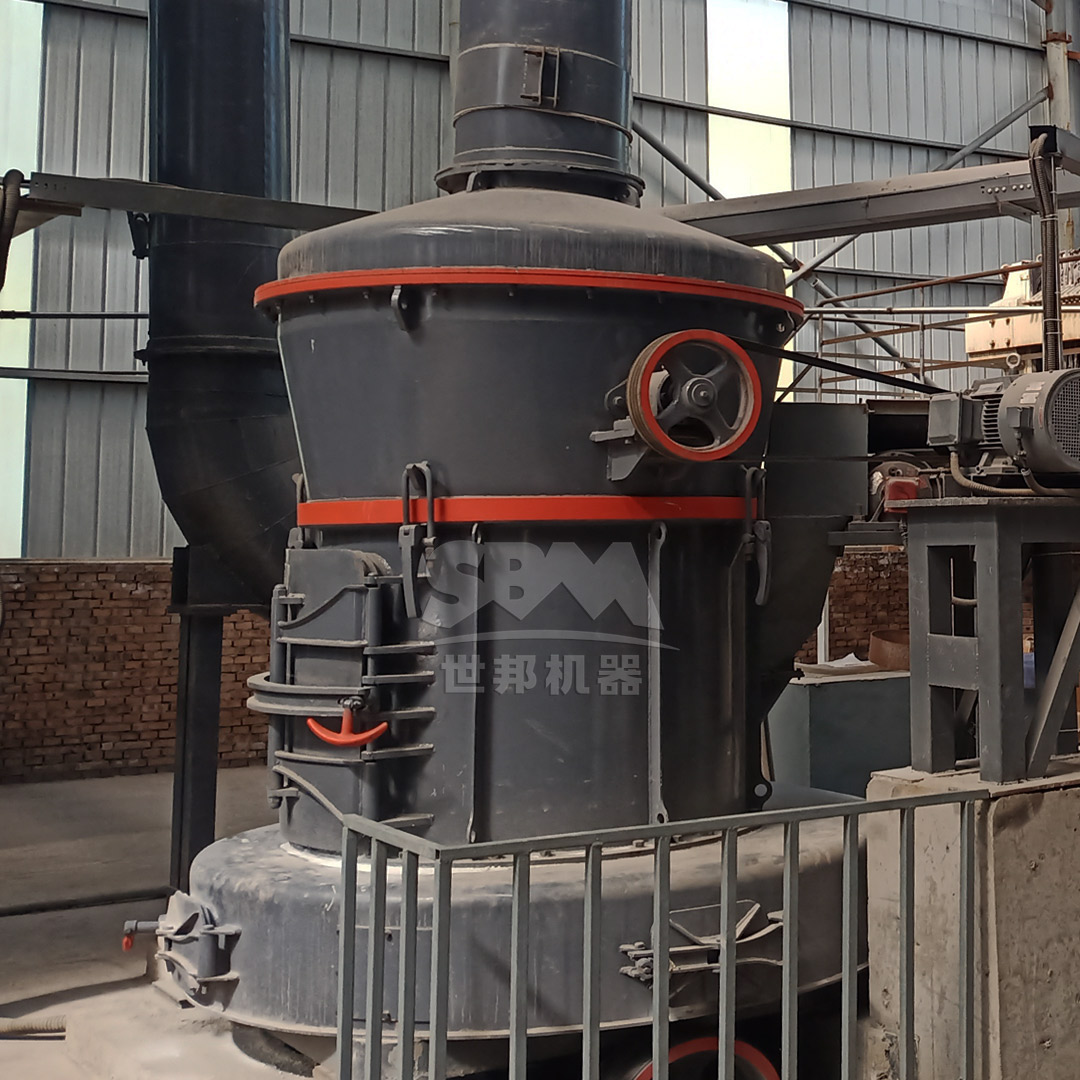

For modern, high-capacity gypsum powder production lines, the Vertical Roller Mill (VRM) has become the equipment of choice. Its integrated design combines grinding, drying, classification, and conveying into a single unit, offering significant advantages in energy savings (30-40% lower than ball mill systems) and reduced plant footprint. The material is ground between rollers and a rotating table, with hot air simultaneously drying the feed. This makes VRMs particularly suitable for gypsum that may contain inherent or surface moisture.

For investors seeking an efficient, reliable, and economical solution for cement-grade gypsum production, our LM Series Vertical Roller Mill stands out as a premier recommendation. Engineered for mineral grinding applications like gypsum, it embodies the latest advancements in dry grinding technology.

Why the LM Series is Ideal for Gypsum:

| Model Example | Grinding Table Diameter | Capacity* (t/h) | Output Fineness | Main Motor Power |

|---|---|---|---|---|

| LM150K | Φ1500mm | 13-38 | 170-40μm (approx. 90-325 mesh) | 280 kW |

| LM190K | Φ1900mm | 23-68 | 170-40μm (approx. 90-325 mesh) | 500 kW |

| LM220K | Φ2200mm | 36-105 | 170-45μm (approx. 90-325 mesh) | 800 kW |

*Capacity varies based on gypsum hardness, moisture, and required fineness.

Beyond the core mill, a fully functional production line requires robust supporting equipment:

To maximize the efficiency of a gypsum powder line, consider the following:

Establishing a competitive cement-grade gypsum powder production line hinges on selecting technology that balances high output, low energy consumption, and product quality. The Vertical Roller Mill, particularly our advanced LM Series, represents the industry benchmark for such applications. Its integrated design, remarkable energy efficiency, and environmental performance make it an investment that pays dividends through lower operating costs and reliable, high-quality powder production. When planning a new line or upgrading an existing one, partnering with an equipment supplier that offers proven technology like the LM Series Vertical Roller Mill is a decisive step toward long-term operational success and sustainability.