China dominates the global kaolin processing equipment market with cutting-edge grinding technologies. This article evaluates the top 5 suppliers offering advanced solutions for achieving 5-325μm particle sizes, focusing on their flagship equipment and technological innovations.

The Chinese kaolin equipment market reached $1.2 billion in 2023, with 18% annual growth driven by demand for ultra-fine powders in paper, ceramics, and cosmetics industries.

Pioneers in ultra-fine grinding systems with patented classification technology. Their SCM Ultrafine Mill achieves industry-leading 5μm fineness:

| Model | Capacity (t/h) | Power (kW) | Fineness (μm) |

|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 5-45 |

| SCM1680 | 5.0-25 | 315 | 5-45 |

Key advantages include:

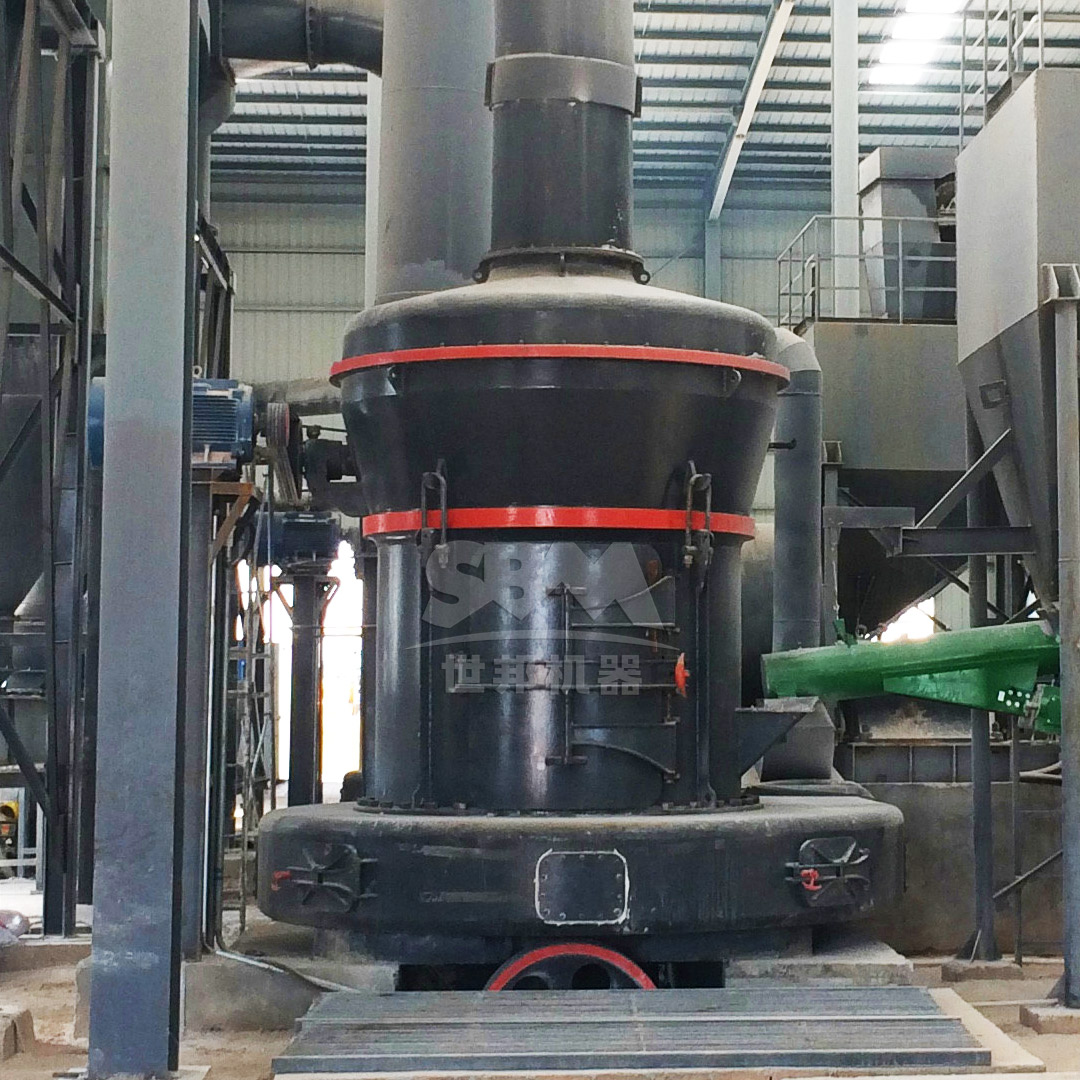

Specialists in large-scale trapezium grinding systems. Their MTW Series mills handle 3-45t/h capacities with curved air duct designs that reduce energy loss by 15%.

Developers of the revolutionary LUM vertical mill featuring:

Manufacturers of the MTM medium-speed mill with spring pressure compensation that extends roller life by 30%.

Providers of complete ball mill systems with 0.074-0.8mm output range, ideal for coarse kaolin grinding.

| Technology | Fineness Range | Energy Efficiency | Maintenance Cycle |

|---|---|---|---|

| Ultrafine Mill | 5-45μm | High | 2000h |

| Trapezium Mill | 45-325μm | Medium | 1500h |

| Ball Mill | 74-800μm | Low | 800h |

For premium kaolin processing, our MTW Series Trapezium Mill delivers exceptional performance:

Key model specifications:

| Model | Capacity (t/h) | Main Motor (kW) | Feed Size (mm) |

|---|---|---|---|

| MTW110 | 3-9 | 55 | <30 |

| MTW215G | 15-45 | 280 | <50 |

Chinese manufacturers lead in kaolin processing technology through continuous innovation. For operations requiring 5-45μm ultra-fine powders, the SCM Ultrafine Mill represents the pinnacle of grinding technology, while the MTW Series provides robust mid-range solutions. Proper equipment selection should consider production scale, target fineness, and total cost of ownership.