Talc powder, a naturally occurring hydrated magnesium silicate, is a cornerstone mineral in the formulation of modern paints and coatings. Its unique platy structure, chemical inertness, and lamellar morphology contribute significantly to enhancing key performance characteristics. From improving rheological properties and mechanical strength to optimizing optical characteristics and corrosion resistance, talc’s multifaceted role is indispensable. The efficacy of talc, however, is profoundly dependent on its particle size distribution, purity, and morphology, which are directly determined by the grinding technology used in its processing. This article delves into the specific benefits of talc in paint formulations and highlights the critical importance of advanced milling equipment, such as our SCM Ultrafine Mill and MTW Series Trapezium Mill, in producing the high-quality talc fillers demanded by the industry.

The value of talc in paint systems stems from a combination of its physical and chemical properties.

The lamellar or plate-like structure of talc particles is its most defining feature. In a liquid paint film, these plates orient themselves parallel to the substrate and to each other as the film dries. This orientation creates a reinforcing barrier that:

Talc is chemically inert, meaning it does not react with other components in the paint formulation. This ensures long-term stability and prevents unwanted side reactions. Furthermore, its low oil absorption value (typically between 40-50 g/100g) is a major advantage:

The particle size of talc directly influences the gloss of a coating. Coarser talc grades are highly effective flatting agents. Their microscopic particles scatter light at the surface of the paint film, reducing specular reflection and resulting in a low-sheen, matte finish desirable for many interior wall paints and primers.

In primer and undercoat applications, talc contributes to a hard, smooth film that sands easily and uniformly without clogging the sandpaper. This property is crucial for achieving the perfect surface finish in woodworking and automotive refinishing applications.

The beneficial properties of talc are not automatically conferred; they must be unlocked through precise and controlled grinding. The goal is to liberate the natural plates without over-grinding them into isometric (rounded) particles, which would diminish their reinforcing and barrier effects. Key grinding objectives include:

To achieve the exacting standards required for high-performance paint-grade talc, advanced milling technology is non-negotiable. Our grinding solutions are engineered to meet these challenges head-on.

For applications demanding the finest talc powders with superior whiteness and preserved platelet structure, our SCM Ultrafine Mill is the ideal solution. This mill is specifically designed for producing micron and sub-micron sized powders with exceptional efficiency.

Why it excels for premium talc:

With models like the SCM1250 (handling 2.5-14 ton/h with a 185kW motor), producers can achieve large-scale output of consistently high-quality ultrafine talc, making it a cornerstone for advanced coating formulations.

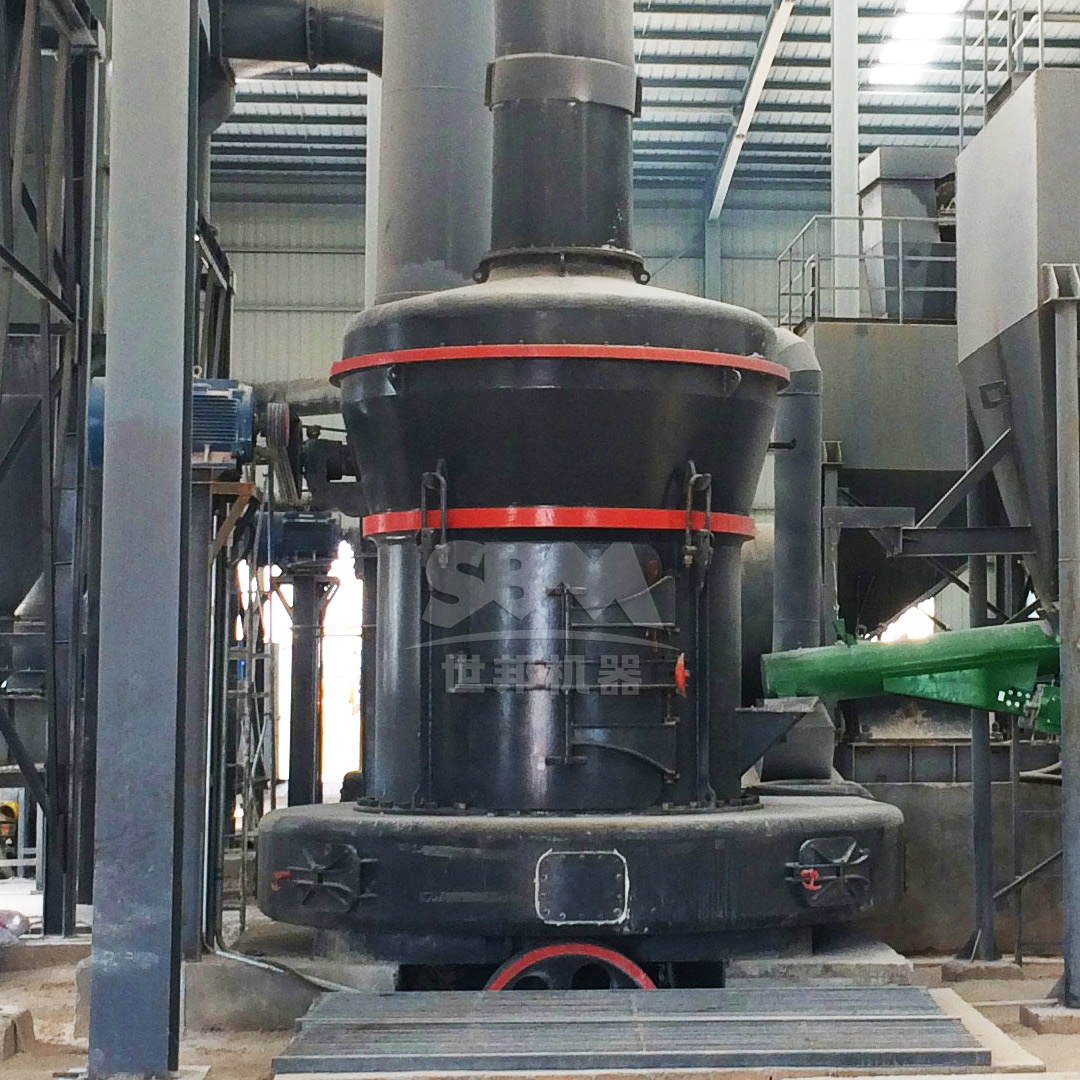

For the production of high-volume, paint-grade talc where excellent flatting, reinforcement, and barrier properties are the priorities, our MTW Series Trapezium Mill offers an unbeatable combination of capacity, efficiency, and product quality.

Why it excels for standard paint-grade talc:

This mill provides the robust and reliable performance needed to produce tons of consistent, high-value talc filler day in and day out.

| Property | Benefit in Paints & Coatings | Influenced by Grinding Process |

|---|---|---|

| Particle Shape (Platy) | Reinforcement, Barrier, Crack Resistance | Must be preserved (avoid impact milling) |

| Particle Size Distribution | Gloss Control, Opacity, Smoothness | Precise classification is critical |

| Brightness / Whiteness | Color Quality, Hiding Power | Avoid metallic contamination |

| Chemical Purity | Coating Stability, Durability | Maintained by inert grinding system |

Talc powder remains a vital functional filler and extender in the paint and coatings industry, delivering an unmatched combination of performance enhancements that few other minerals can offer. Its ability to improve durability, control aesthetics, and protect substrates is directly tied to its physical properties, which are, in turn, dictated by the technology used to process it. Investing in advanced, precise, and efficient grinding technology is not merely an operational decision but a strategic one that defines product quality. Our SCM Ultrafine Mill and MTW Series Trapezium Mill represent the pinnacle of this technology, engineered to unlock the full potential of talc and empower formulators to create the next generation of high-performance coatings.