Grinding mills represent one of the most critical pieces of equipment in modern industrial processing, serving as the backbone for size reduction operations across countless sectors. From mining and minerals to chemicals, construction materials, and advanced ceramics, the ability to efficiently reduce particle size directly impacts product quality, production costs, and environmental compliance. The evolution of grinding technology has enabled manufacturers to achieve increasingly finer particle distributions while simultaneously addressing the growing demands for energy efficiency, operational reliability, and environmental sustainability.

Modern industrial applications present unique challenges that require specialized grinding solutions. Variations in material hardness, abrasiveness, moisture content, and desired final particle size distribution necessitate careful equipment selection and process optimization. This article explores how advanced grinding mill technologies can be adapted to meet the specific requirements of diverse industrial applications, with particular focus on innovative solutions that deliver superior performance across multiple operational parameters.

At its core, grinding involves the mechanical breakdown of solid materials through the application of various forces including compression, impact, and attrition. The efficiency of this process depends on multiple factors including the material’s physical properties, the grinding mechanism employed, and the operational parameters of the equipment. Understanding these fundamentals is essential for selecting the appropriate grinding technology for specific industrial applications.

The grindability of a material—its resistance to size reduction—varies significantly based on factors such as hardness, toughness, moisture content, and chemical composition. Materials with high hardness but low toughness (brittle materials) typically grind more efficiently than those with high toughness but lower hardness. Moisture content can significantly impact grinding efficiency, with excessively wet materials causing clogging and reduced throughput, while overly dry materials may generate excessive dust.

Different grinding mills employ distinct mechanisms for particle size reduction. Compression grinding applies gradual pressure to fracture particles, making it suitable for hard, abrasive materials. Impact grinding utilizes high-speed collisions to shatter particles, effective for brittle materials. Attrition grinding involves particle-on-particle abrasion in a bed of material, ideal for producing fine and ultra-fine powders. Many modern mills combine multiple mechanisms to optimize efficiency across a wider range of materials.

Grinding operations are notoriously energy-intensive, often accounting for a significant portion of a plant’s total energy consumption. The relationship between energy input and particle size reduction follows established principles such as Rittinger’s, Kick’s, and Bond’s laws, which describe the energy required to create new surface area. Modern grinding mills incorporate design features that maximize the proportion of energy directed toward productive size reduction while minimizing losses to heat, vibration, and noise.

Different industries present unique challenges that demand specialized grinding approaches. Understanding these application-specific requirements is crucial for selecting the optimal grinding technology and configuring it for peak performance.

The mining industry requires robust grinding solutions capable of processing large volumes of hard, abrasive ores. Key considerations include wear resistance, throughput capacity, and the ability to handle variations in feed material. Grinding circuits in mineral processing often involve multiple stages, with primary crushing followed by secondary and tertiary grinding to liberate valuable minerals from gangue material. The final particle size distribution directly impacts downstream processes such as flotation, leaching, or magnetic separation.

Chemical and pharmaceutical applications demand precise control over particle size distribution, often requiring ultra-fine grinding with narrow particle size distributions. Contamination avoidance is critical, necessitating materials of construction that prevent product contamination. Many pharmaceutical applications require aseptic processing conditions and validation of cleaning procedures between product batches. The ability to maintain consistent product quality while preventing cross-contamination is paramount.

Cement, lime, and other construction materials require grinding solutions that balance production capacity with energy consumption. The cement industry, in particular, has driven innovations in grinding technology due to the massive scale of production and the energy-intensive nature of clinker grinding. Modern cement plants increasingly utilize vertical roller mills that combine grinding and drying operations, significantly reducing specific energy consumption compared to traditional ball mills.

Modern grinding mills incorporate sophisticated technologies that enable them to adapt to the specific requirements of different industries and materials. These advancements span mechanical design, control systems, and auxiliary equipment integration.

Applications requiring particle sizes in the micrometer and sub-micrometer range demand specialized ultra-fine grinding technologies. These systems typically incorporate high-precision classification systems that separate particles based on size, returning oversize material for further grinding. The SCM Ultrafine Mill represents a prime example of this technology, capable of producing powders with fineness ranging from 325 to 2500 mesh (D97 ≤ 5μm). With capacity ranging from 0.5 to 25 tons per hour depending on model, this mill delivers exceptional performance for applications requiring extremely fine particle distributions.

The SCM Ultrafine Mill incorporates several advanced features that make it particularly suitable for demanding applications. Its vertical turbine classifier enables precise particle size control, ensuring consistent product quality without coarse particle contamination. The mill’s unique grinding chamber design, featuring special material rollers and grinding rings, extends component life while maintaining stable operation. From an environmental perspective, the integrated pulse dust collection system exceeds international standards while the soundproof chamber design maintains noise levels below 75dB.

For applications requiring high throughput with moderate fineness requirements, trapezium mills offer an optimal balance of capacity, energy efficiency, and product quality. The MTW Series Trapezium Mill processes feed materials up to 50mm in size, producing powders ranging from 30 to 325 mesh with capacities from 3 to 45 tons per hour. Its wear-resistant shovel design incorporates combined shovel plates that reduce maintenance costs, while the curved air channel design minimizes airflow energy loss, improving transmission efficiency.

The MTW Series incorporates several patented technologies that enhance its performance across diverse applications. The bevel gear integral transmission achieves 98% transmission efficiency while saving space and reducing installation costs. The wear-resistant volute structure employs a non-blocking design that improves air classification efficiency while reducing maintenance costs by 30%. These features make the MTW Series particularly suitable for large-scale operations in industries such as mining, power plant desulfurization, and construction materials.

| Application Sector | Recommended Mill Type | Typical Fineness Range | Key Considerations |

|---|---|---|---|

| Mining & Minerals | LM Vertical Roller Mill | 30-325 mesh | Wear resistance, high capacity |

| Chemicals & Pharmaceuticals | SCM Ultrafine Mill | 325-2500 mesh | Precise classification, contamination control |

| Construction Materials | MTW Trapezium Mill | 30-325 mesh | Energy efficiency, high throughput |

| Advanced Ceramics | LUM Ultra-fine Vertical Mill | 325-2500 mesh | Ultra-fine grinding, narrow distribution |

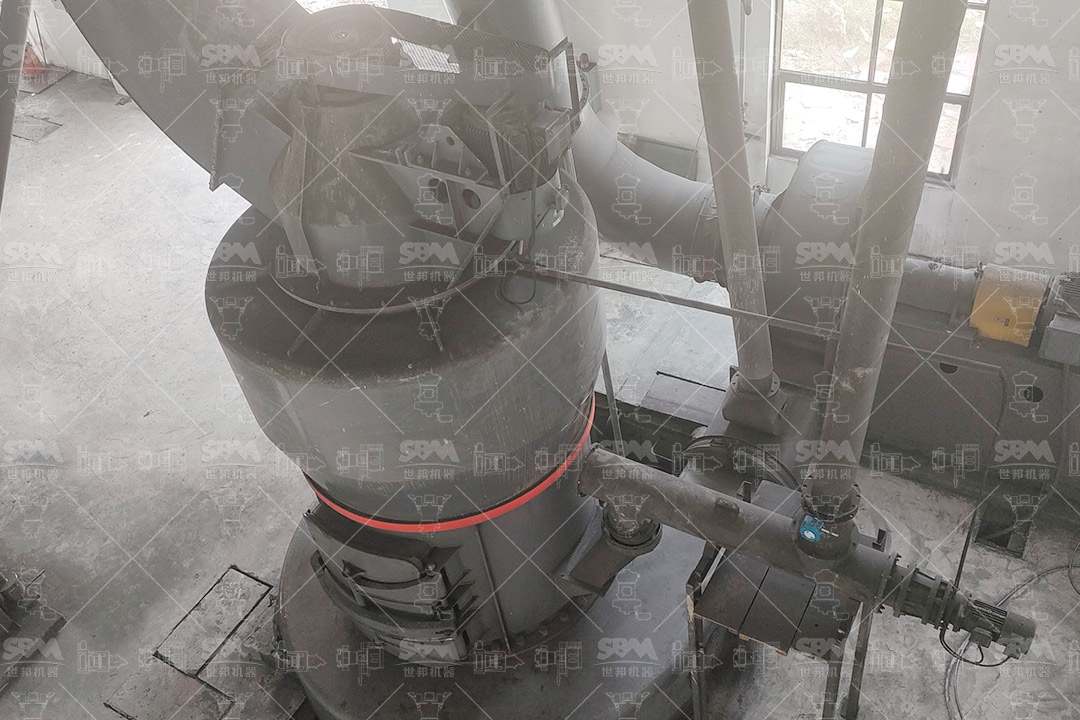

Vertical roller mills have revolutionized grinding operations in numerous industries by integrating multiple functions into a single compact unit. The LM Series Vertical Roller Mill combines crushing, grinding, and separation operations while reducing footprint requirements by up to 50% compared to traditional grinding systems. With capacity ranging from 3 to 250 tons per hour depending on model and application, these mills offer exceptional flexibility for diverse industrial requirements.

The LM Series incorporates several innovative features that enhance its adaptability. The non-contact design between grinding rollers and the grinding table extends wear part life up to three times compared to conventional designs. The intelligent control system enables both remote and local operation with real-time monitoring of operational parameters, reducing manual intervention. From an environmental perspective, the fully sealed negative pressure operation maintains dust emissions below 20mg/m³ while operating noise remains below 80dB(A).

Beyond equipment selection, optimizing grinding processes requires careful consideration of operational parameters, auxiliary systems, and maintenance strategies. Proper optimization can significantly impact production costs, product quality, and equipment longevity.

Modern grinding mills increasingly incorporate sophisticated control systems that monitor and adjust operational parameters in real-time. These systems typically track variables such as feed rate, motor load, grinding pressure, and product fineness, making automatic adjustments to maintain optimal performance. Advanced systems may incorporate expert control algorithms that learn from operational data to further optimize performance over time. The integration of these control systems with plant-wide distributed control systems enables comprehensive process optimization across multiple unit operations.

The performance of grinding mills depends significantly on properly integrated auxiliary equipment. Feed systems must deliver material at a consistent rate and composition to maintain stable operation. Classification systems separate fine product from coarse material that requires further grinding, with efficiency directly impacting overall circuit performance. Dust collection systems must handle the significant air volumes required for material transport and classification while meeting environmental emissions standards. Proper design and integration of these auxiliary systems is essential for achieving optimal grinding circuit performance.

Effective maintenance is critical for maximizing equipment availability and minimizing life-cycle costs. Predictive maintenance strategies utilizing vibration analysis, lubricant analysis, and thermal imaging can identify developing issues before they cause unplanned downtime. Modern grinding mills increasingly incorporate design features that facilitate maintenance, such as modular roller assemblies that can be replaced quickly without extensive disassembly. The implementation of comprehensive maintenance planning, including strategic spare parts inventory management, ensures that necessary components are available when required.

Modern grinding operations must address increasingly stringent environmental regulations while simultaneously improving sustainability through reduced energy consumption and minimized waste generation.

Grinding operations inherently generate dust, requiring effective collection and control systems. Modern mills typically incorporate integrated baghouse filters or cartridge collectors that capture particulate matter with efficiency exceeding 99.9%. Advanced pulse-jet cleaning systems maintain filter performance while minimizing compressed air consumption. The selection of appropriate filter media depends on operational conditions including temperature, humidity, and material characteristics. Proper system design ensures that emissions consistently comply with regulatory requirements while maintaining operational efficiency.

Grinding mills generate significant noise from multiple sources including mechanical impacts, air movement, and motor operation. Modern designs incorporate numerous noise reduction features including acoustic enclosures, vibration isolation, and optimized mechanical designs that minimize impact forces. Sound-absorbing materials applied to mill internals and enclosures can reduce noise transmission. Proper maintenance, including timely replacement of worn components, prevents noise levels from increasing over time. These measures collectively enable modern grinding mills to operate within acceptable noise limits even in sensitive environments.

With grinding operations accounting for a substantial portion of industrial energy consumption, continuous improvements in energy efficiency deliver significant economic and environmental benefits. Modern grinding mills incorporate numerous energy-saving features including high-efficiency motors, optimized mechanical drives, and intelligent control systems that minimize energy consumption during transient operations. Some advanced systems recover and reuse energy from process air streams, further reducing net energy requirements. The selection of appropriately sized equipment for specific applications prevents energy waste associated with operating oversized equipment at reduced capacity.

The evolution of grinding technology continues, driven by demands for improved efficiency, enhanced control, and reduced environmental impact. Several emerging trends promise to further transform industrial grinding operations in the coming years.

The integration of digital technologies is enabling new approaches to grinding optimization. Industrial Internet of Things (IIoT) sensors provide unprecedented visibility into equipment condition and process performance. Cloud-based analytics platforms process operational data to identify optimization opportunities and predict maintenance requirements. Digital twin technology creates virtual replicas of grinding circuits, enabling simulation of operational changes without disrupting production. These digital technologies collectively enable more proactive, data-driven decision-making that optimizes grinding performance across multiple parameters.

Innovations in materials science and manufacturing are producing grinding components with significantly improved wear resistance and service life. Advanced ceramics, metal matrix composites, and specially formulated alloys withstand abrasive wear more effectively than traditional materials. Additive manufacturing techniques enable the production of complex component geometries that were previously impossible or prohibitively expensive to manufacture. Surface engineering treatments including specialized hardfacing alloys and thermal spray coatings further extend component life in demanding applications.

Future grinding systems may increasingly combine multiple grinding technologies to optimize performance across different particle size ranges. Hybrid systems might utilize high-pressure grinding rolls for pre-treatment followed by stirred media mills for fine grinding, achieving superior overall efficiency compared to either technology alone. The integration of advanced classification systems that more precisely separate particles based on multiple characteristics including size, shape, and density will enable more targeted grinding of specific fractions. These hybrid approaches promise to deliver step-change improvements in grinding efficiency and product quality.

The adaptation of grinding mill processes for diverse industrial applications requires a comprehensive understanding of both equipment capabilities and application-specific requirements. Modern grinding technologies offer sophisticated solutions that can be tailored to meet the unique challenges presented by different materials, production scales, and quality specifications. The continued evolution of grinding technology, driven by digitalization, advanced materials, and hybrid system approaches, promises to deliver further improvements in efficiency, control, and sustainability.

Successful implementation of grinding technology requires careful consideration of the complete grinding circuit, including auxiliary equipment and control systems. Proper equipment selection, based on thorough analysis of operational requirements, ensures optimal performance across the equipment lifecycle. As industrial processes continue to evolve toward greater efficiency and sustainability, advanced grinding technologies will play an increasingly critical role in enabling these improvements across diverse manufacturing sectors.