Bamboo charcoal, a versatile and eco-friendly material, has gained significant traction across various industries, including water purification, air filtration, agriculture, and personal care. Its unique porous structure, high adsorption capacity, and mineral-rich composition make it a superior alternative to traditional activated carbon. However, transforming raw bamboo into high-value charcoal products requires a sophisticated and efficient processing line. This guide provides a comprehensive overview of the essential stages and equipment needed for a modern bamboo charcoal production facility, from raw material preparation to final packaging.

A complete production line is a systematic integration of several key processes. Each stage must be carefully designed to ensure product quality, operational efficiency, and economic viability.

The journey begins with raw bamboo. Logs are first cut into uniform lengths and split into smaller pieces to ensure consistent carbonization. The prepared bamboo is then loaded into a carbonization furnace (or kiln). This is a critical stage where bamboo is heated in an oxygen-limited environment at high temperatures (typically between 600°C to 1000°C). The process drives off volatile compounds and moisture, leaving behind raw bamboo charcoal. Modern carbonization furnaces are designed for energy efficiency, with systems to recover and utilize the pyrolysis gases as fuel.

| Process Stage | Key Equipment | Primary Function |

|---|---|---|

| Raw Material Prep | Chipper, Cutter, Splitter | Size reduction for uniform processing |

| Carbonization | Carbonization Furnace/Kiln | Converts bamboo to raw charcoal in a controlled atmosphere |

| Activation (Optional) | Steam Activation Furnace | Enhances porosity and surface area for high-grade activated carbon |

The raw charcoal lumps exiting the furnace are too large for most applications. The first size reduction stage involves coarse crushing. A Hammer Mill is exceptionally well-suited for this task. Its high-speed rotating hammers effectively shatter the brittle charcoal lumps into smaller granules (typically 0-3mm). Key advantages for charcoal processing include its high crushing ratio, robust construction with wear-resistant liners (crucial for abrasive materials), and simple, low-maintenance design. Models like the PC4012-90, with a capacity of 15-40 tons per hour, are ideal for medium to large-scale operations.

For applications requiring ultrafine bamboo charcoal powder—such as in cosmetics, high-efficiency filters, or composite materials—a specialized fine grinding mill is indispensable. This is where the selection of the right grinding technology becomes paramount for product quality and operational cost.

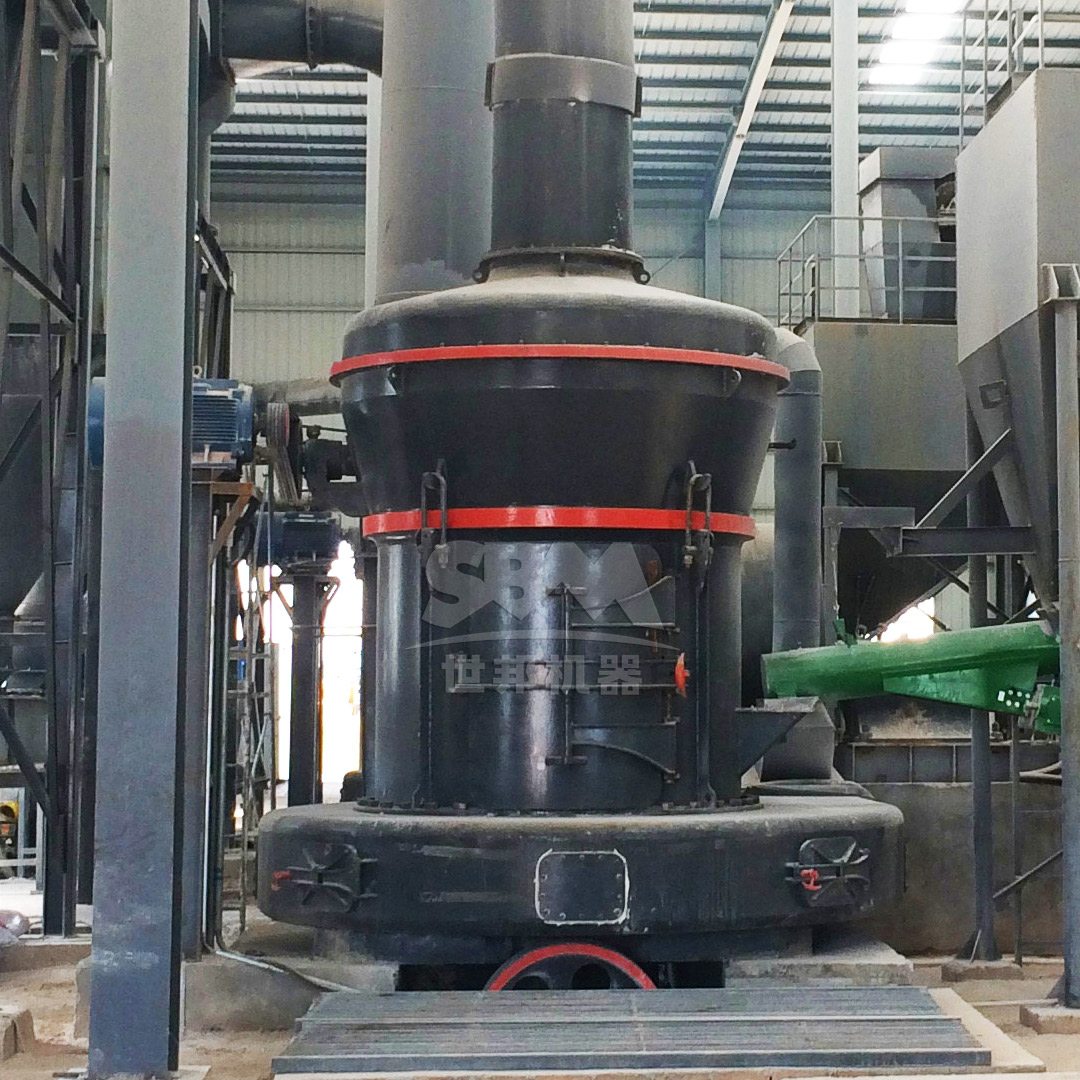

For producing fine to medium-fine powders (30-325 mesh, or 600-45μm), the MTW Series European Trapezium Mill offers an outstanding balance of performance and durability. Its anti-wear shovel design and optimized arc air duct minimize maintenance costs and energy loss. The integral bevel gear drive ensures high transmission efficiency (up to 98%) and stable operation, making it a reliable workhorse for continuous production. It is perfectly capable of handling the output from the hammer mill to create a consistent medium-fine powder.

However, for the highest value-added products requiring ultrafine powders (325-2500 mesh, or 45-5μm), the SCM Series Ultrafine Mill is the industry-leading solution. Its technological advantages are particularly relevant for premium bamboo charcoal:

The mill operates on a layer-by-layer grinding principle, where materials are crushed by roller pressure against rotating grinding rings. For a production line targeting the high-end market, integrating an SCM1000 model (capacity: 1.0-8.5 t/h, fineness: 325-2500 mesh) would be a strategic investment to produce superior ultrafine bamboo charcoal powder.

After grinding, the powder must be classified to meet specific particle size distribution requirements. Modern grinding mills like the SCM and MTW series often have integrated high-efficiency classifiers (e.g., dynamic or turbine classifiers). For final product refinement, independent vibrating screens or air classifiers are used to separate the powder into different grades, removing any oversize or undersize particles to guarantee batch consistency.

The final stages involve handling the finished powder. Enclosed screw conveyors or pneumatic conveying systems transport the powder to storage silos, preventing dust emission and contamination. Automated weighing and packaging machines then bag the product for sale. The entire conveying and storage system should be designed for dust-tight operation to protect product quality and worker health.

Establishing a successful bamboo charcoal processing plant hinges on the integration of robust, efficient, and appropriately selected equipment. The core of the value-adding process lies in the grinding and classification stages. While equipment like hammer mills provide essential primary crushing, investing in advanced grinding technology such as the MTW Series European Trapezium Mill for fine powders or the flagship SCM Series Ultrafine Mill for premium ultrafine products is crucial for competitiveness. By carefully planning each segment of the production line—from carbonization to packaging—and selecting machinery designed for durability, low energy consumption, and precise control, producers can maximize yield, ensure superior product quality, and secure a strong position in the growing global market for bamboo charcoal products.