Barite, also known as barium sulfate, has emerged as a critical component in modern soundproofing materials due to its exceptional density and acoustic absorption properties. With a specific gravity of 4.3-4.6, barite possesses one of the highest densities among non-metallic minerals, making it ideal for creating mass-loaded vinyl and composite sound barriers. The effectiveness of barite in soundproofing applications is directly related to the particle size distribution and purity achieved through precise grinding processes. High-performance soundproofing materials require barite powder with controlled particle morphology and narrow size distribution to maximize acoustic impedance while maintaining flexibility and durability in the final product.

The production of high-performance soundproofing materials demands barite powder with specific technical characteristics that can only be achieved through advanced grinding technology. The optimal particle size range for soundproofing applications falls between 325 mesh (45μm) and 2500 mesh (5μm), with D97 distribution being particularly critical for consistent acoustic performance. Finer particles improve the material’s ability to fill microscopic voids and create homogeneous sound barriers, while maintaining appropriate particle morphology to ensure proper binding in polymer matrices. Additionally, the grinding process must preserve the natural crystalline structure of barite to maintain its high density characteristics, which are essential for effective sound transmission loss.

| Application Type | Optimal Particle Size Range | D97 Requirement | Specific Surface Area |

|---|---|---|---|

| Mass-Loaded Vinyl | 325-800 mesh | ≤18μm | ≥4500 cm²/g |

| Acoustic Composites | 800-1250 mesh | ≤10μm | ≥6800 cm²/g |

| High-Performance Barriers | 1250-2500 mesh | ≤5μm | ≥12000 cm²/g |

Modern barite processing for soundproofing applications requires grinding equipment capable of delivering precise particle size control while maintaining high throughput and energy efficiency. Traditional grinding methods often fail to achieve the narrow particle distribution required for premium soundproofing materials, leading to inconsistent performance and reduced product quality. Advanced grinding systems must incorporate precision classification technology, wear-resistant components for contamination-free operation, and intelligent control systems to maintain consistent product quality despite variations in raw material characteristics.

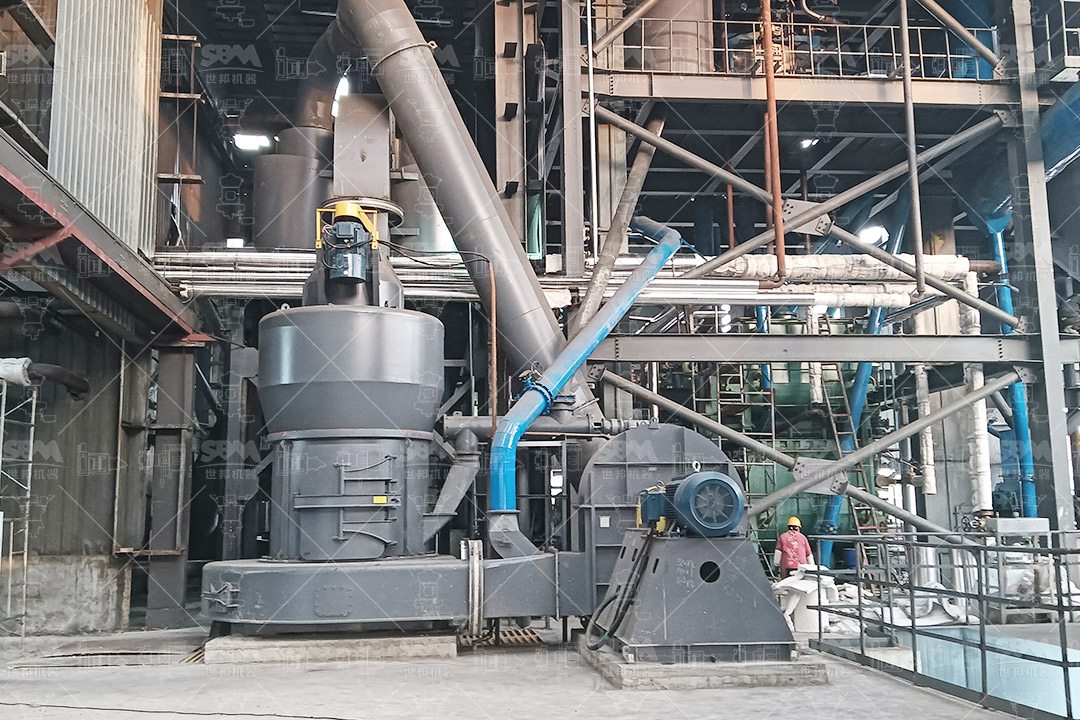

For soundproofing material manufacturers requiring the finest barite powders, our SCM Ultrafine Mill represents the ideal grinding solution. This advanced mill system specializes in producing barite powder in the 325-2500 mesh range (D97≤5μm), precisely matching the requirements for high-performance soundproofing applications. The mill’s vertical turbine classification system ensures precise particle size切割 with no coarse powder contamination, guaranteeing consistent acoustic performance in the final product. With capacity ranging from 0.5 to 25 tons per hour depending on the model, the SCM series can accommodate both specialized soundproofing material producers and large-scale industrial operations.

The SCM Ultrafine Mill’s energy-efficient design reduces power consumption by 30% compared to conventional jet mills while doubling production capacity, significantly lowering the operating costs for soundproofing material manufacturers. The special material grinding rollers and rings provide extended service life, ensuring consistent product quality and reducing maintenance downtime. Furthermore, the mill’s integrated pulse dust collection system exceeds international environmental standards, while the soundproof chamber design maintains operational noise below 75dB, creating a comfortable working environment that aligns with the acoustic focus of the end products.

For soundproofing material manufacturers requiring high-volume production of barite powder in the 30-325 mesh range, our MTW Series Trapezium Mill offers an exceptional balance of capacity, efficiency, and product quality. With processing capacity ranging from 3 to 45 tons per hour, this mill system can support the production demands of large-scale soundproofing material factories. The innovative curved air channel design minimizes energy loss during material transport, while the combined blade system reduces maintenance costs and extends component life. The MTW series’ integrated cone gear transmission achieves 98% transmission efficiency, significantly reducing energy consumption per ton of processed barite.

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Output Fineness (mesh) | Recommended Application |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 325-2500 | Premium soundproofing materials |

| SCM1250 | 2.5-14 | 185 | 325-2500 | Medium-scale production |

| SCM1680 | 5.0-25 | 315 | 325-2500 | Large-scale industrial production |

| MTW138Z | 6-17 | 90 | 30-325 | Standard soundproofing products |

| MTW215G | 15-45 | 280 | 30-325 | High-volume manufacturing |

The relationship between barite grinding technology and soundproofing performance is multifaceted and critically important. Properly ground barite powder with optimal particle size distribution significantly enhances the sound transmission class (STC) and noise reduction coefficient (NRC) of acoustic materials. The particle morphology achieved through advanced grinding affects both the packing density within polymer matrices and the interfacial bonding strength, directly influencing the material’s ability to dissipate sound energy through viscoelastic damping mechanisms. Furthermore, consistent particle size distribution prevents the formation of acoustic bridges that can compromise sound barrier performance.

Research has demonstrated that barite powder with D97 ≤ 5μm can improve sound transmission loss by 3-5 dB in the critical 500-2000 Hz frequency range compared to conventionally ground barite. This improvement is attributed to better particle packing that eliminates microscopic air gaps that would otherwise transmit sound waves. The controlled particle size distribution also enhances the material’s performance at lower frequencies, which are typically more challenging to block and require higher mass and better damping characteristics.

The selection of appropriate grinding technology significantly impacts the economic viability of soundproofing material production. While initial investment in advanced grinding systems like the SCM Ultrafine Mill or MTW Trapezium Mill may be higher than conventional alternatives, the long-term operational benefits create substantial cost advantages. The energy efficiency of these systems, combined with reduced maintenance requirements and higher product yield, results in lower production costs per ton of finished soundproofing material. Additionally, the consistent product quality reduces waste and improves manufacturing efficiency throughout the production chain.

| Cost Factor | Conventional Mill | SCM Ultrafine Mill | MTW Trapezium Mill |

|---|---|---|---|

| Energy Consumption (kWh/ton) | 85-110 | 55-70 | 45-60 |

| Maintenance Cost (% of initial investment/year) | 8-12% | 4-6% | 3-5% |

| Product Yield (%) | 85-90% | 94-97% | 92-95% |

| Wear Part Replacement Frequency (months) | 6-8 | 12-18 | 10-15 |

The soundproofing materials industry continues to evolve toward higher performance standards and more sustainable manufacturing practices. Future barite grinding systems will likely incorporate even more sophisticated classification technology to achieve tighter particle size distributions, potentially targeting specific acoustic frequency ranges. Integration of artificial intelligence and machine learning for real-time process optimization represents another emerging trend, enabling mills to automatically adjust operating parameters in response to variations in raw material characteristics. Additionally, the growing emphasis on circular economy principles is driving development of grinding systems that can efficiently process recycled barite from construction and demolition waste, creating new opportunities for sustainable soundproofing material production.

Advanced grinding systems like our SCM and MTW series are increasingly incorporating IoT connectivity and data analytics capabilities. These smart features enable remote monitoring of mill performance, predictive maintenance scheduling, and automated optimization of grinding parameters based on real-time feedback from particle size analyzers. This digital transformation not only improves operational efficiency but also ensures consistent product quality that meets the exacting standards of modern soundproofing material specifications. The integration of these technologies represents a significant step forward in the digitalization of mineral processing for acoustic applications.

The production of high-performance soundproofing materials requires precisely controlled barite powder with specific particle characteristics that can only be achieved through advanced grinding technology. Our SCM Ultrafine Mill and MTW Series Trapezium Mill provide comprehensive solutions for soundproofing material manufacturers, offering the precise particle size control, energy efficiency, and operational reliability needed to compete in today’s demanding acoustic products market. By selecting the appropriate grinding technology based on specific production requirements and performance targets, manufacturers can optimize both their product quality and economic performance while meeting the evolving needs of the construction, automotive, and industrial noise control sectors.