Barite (BaSO4) is a critical mineral additive in plastic production, enhancing density, UV resistance, and surface finish. Achieving optimal particle size distribution (PSD) requires specialized grinding equipment. This article evaluates key technologies and recommends industrial-grade solutions for barite processing in polymer applications.

| Parameter | Injection Molding Grade | Film Extrusion Grade |

|---|---|---|

| Target D50 (μm) | 3-8 | 1.5-3 |

| Whiteness (ISO) | ≥92% | ≥94% |

| Moisture Content | ≤0.3% | ≤0.2% |

Barite decomposes at 1,580°C but undergoes phase transitions below 200°C during grinding. Excessive heat generation causes:

With Mohs hardness 3-3.5, barite requires:

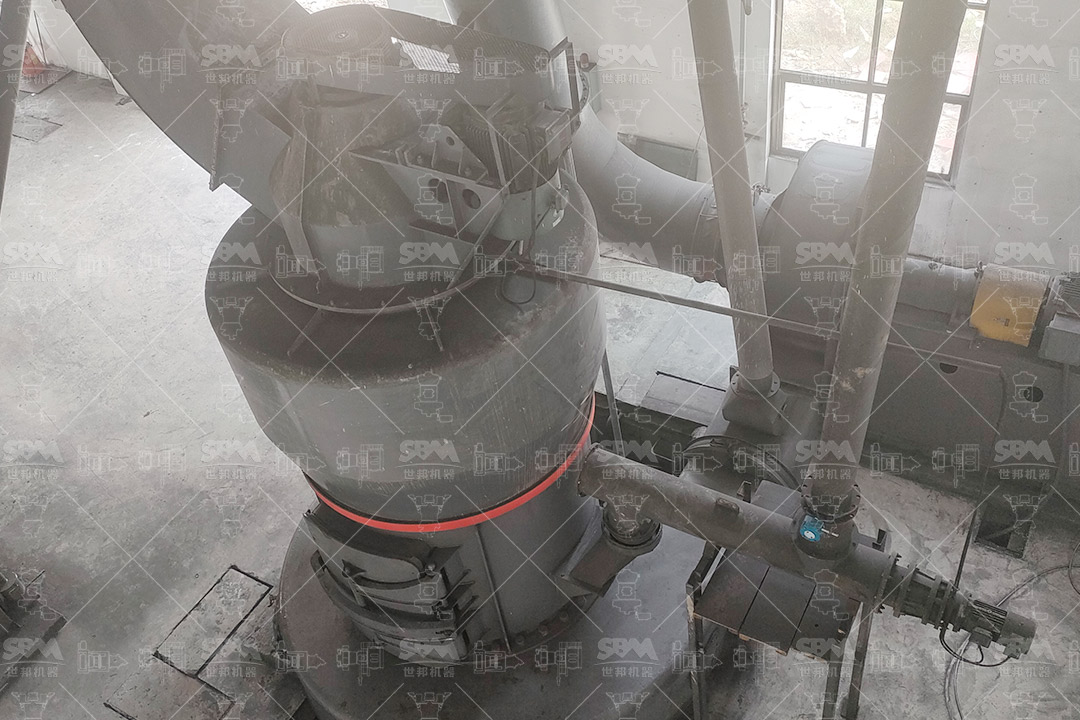

Our SCM Ultrafine Mill series delivers superior performance for barite processing:

| Model | SCM800 | SCM1000 | SCM1680 |

|---|---|---|---|

| Capacity (t/h) | 0.5-4.5 | 1.0-8.5 | 5.0-25 |

| Power (kW) | 75 | 132 | 315 |

| Energy Saving | 30% less than jet mills | ||

For large-scale operations, our MTW Series offers:

A major polymer manufacturer achieved:

Selecting the proper grinding system for barite requires balancing particle size requirements with production scale. Our SCM and MTW series mills provide tailored solutions for plastic applications, combining German engineering with robust construction. Contact our technical team for customized recommendations based on your specific polymer formulation requirements.