The stringent global environmental regulations governing sulfur dioxide (SO₂) emissions from industrial boilers have made flue gas desulfurization (FGD) a critical component of modern power generation and industrial processes. The effectiveness and economic viability of dry or semi-dry FGD systems, which utilize powdered sorbents like limestone (CaCO₃), hydrated lime (Ca(OH)₂), or other alkaline reagents, are fundamentally dependent on the quality of the desulfurization agent. The particle size distribution, specific surface area, and chemical reactivity of the powder directly influence the SO₂ capture efficiency, reagent utilization rate, and overall operational costs. Consequently, the heart of any efficient desulfurization agent production line is a high-performance, reliable, and energy-efficient grinding system. This article delves into the technical requirements for such production lines and presents comprehensive grinding solutions.

Producing an optimal desulfurization agent is not merely about reducing particle size; it involves meeting a precise set of criteria to ensure maximum SO₂ removal efficiency.

The ideal sorbent has a high proportion of fine particles (typically below 45μm or 325 mesh). Finer particles offer a vastly increased surface area for the gas-solid reaction, leading to faster and more complete sulfur capture. However, an overly fine product can increase energy consumption and pose handling challenges. The grinding system must therefore offer precise classification to produce a consistent, targeted fineness.

Power plants and large industrial boilers consume desulfurization agents in massive quantities. The grinding mill must deliver high throughput (often ranging from 10 to over 100 tons per hour) to meet continuous demand. Energy consumption is a major operational cost driver, making mills with superior grinding efficiency and lower specific power consumption (kWh/ton) essential for economic operation.

Production lines must operate continuously with minimal unplanned downtime. Grinding mills for abrasive materials like limestone require robust construction, wear-resistant components, and designs that facilitate easy maintenance and replacement of wearing parts to ensure long service life and stable operation.

The grinding process itself must be clean. A fully sealed system with efficient pulse-jet baghouse dust collectors is mandatory to prevent powder leakage, ensuring a safe working environment and meeting in-plant air quality standards. Low-noise operation is also a significant consideration.

Selecting the right grinding technology depends on the required fineness, capacity, moisture content of the feed material, and overall project economics. Several advanced mill types are well-suited for this application.

For large-scale production of limestone powder for wet or semi-dry FGD systems (fineness range: 325 mesh/45μm to 200 mesh/75μm), the Vertical Roller Mill (VRM) is often the technology of choice. Its integrated design combines drying, grinding, and classification in a single compact unit.

| Model | Grinding Table Diameter | Capacity (t/h)* | Main Motor Power (kW) | Target Fineness |

|---|---|---|---|---|

| LM190K | Φ1900mm | 23 – 68 | 500 | 170-45μm (80-325 mesh) |

| LM220K | Φ2200mm | 36 – 105 | 800 | 170-45μm (80-325 mesh) |

| LM280K | Φ2800mm | 50 – 170 | 1250 | 170-45μm (80-325 mesh) |

*Capacity varies with material hardness and fineness.

Technical Advantages:

For projects requiring flexibility, reliability, and ease of maintenance in the medium-to-fine grinding range (30-325 mesh), the MTW Series European Trapezium Mill stands out. It is an ideal solution for producing hydrated lime or limestone powder for circulating fluidized bed (CFB) boilers and other dry FGD processes.

We highly recommend our MTW Series European Trapezium Mill for desulfurization agent production. Its design incorporates several patented innovations specifically aimed at durability and efficiency when processing abrasive minerals.

Key Features of the MTW Mill:

In applications where maximum surface area and reactivity are paramount, producing ultrafine powders (325-2500 mesh) can significantly enhance desulfurization kinetics and reduce sorbent consumption. For this demanding task, the SCM Series Ultrafine Mill is the premier choice.

Our SCM Ultrafine Mill is engineered to produce the high-quality, superfine powders that can lead to breakthrough performance in advanced FGD systems.

Why SCM is Ideal for Premium Desulfurization Agents:

A successful production line is more than just a mill. It requires a fully integrated system designed for seamless operation.

This includes receiving hoppers, belt conveyors, and primary crushers (like Jaw Crushers or Hammer Mills) to reduce quarried limestone to a size suitable for the grinding mill feed (typically ≤50mm for VRM/MTW, ≤20mm for SCM).

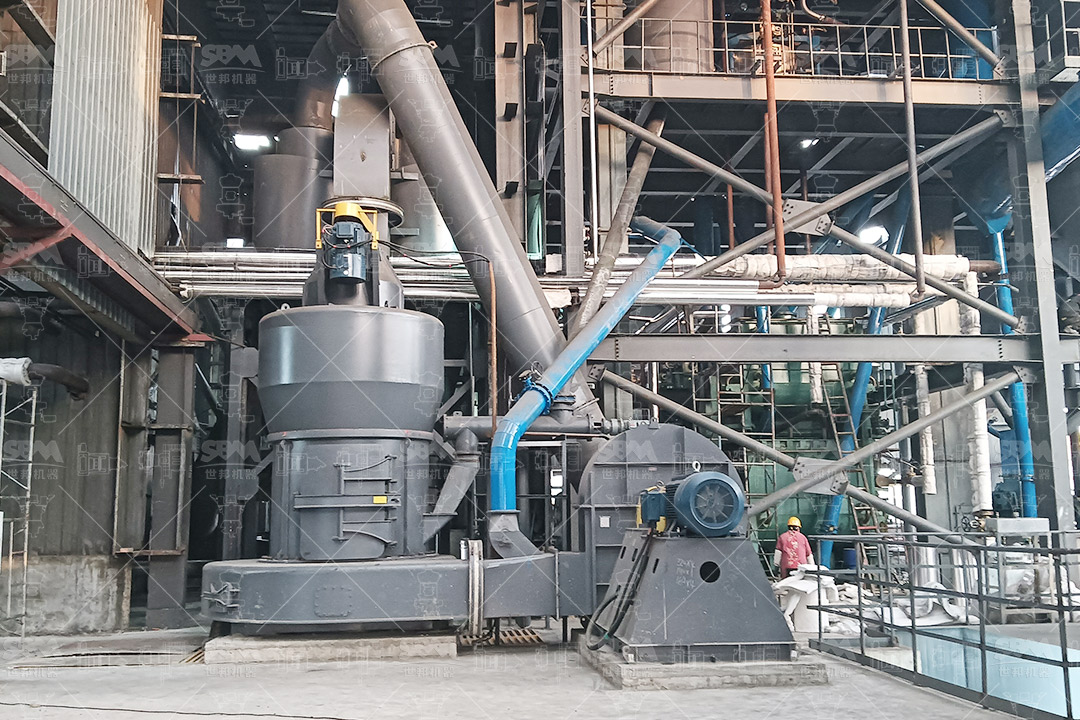

The core section featuring the main mill (e.g., LM, MTW, or SCM), its drive system, classifier, and feeding device (such as a vibrating or screw feeder).

This involves high-efficiency cyclone separators and pulse-jet baghouse dust collectors to separate the fine powder from the air stream. The collected powder is then conveyed via screw conveyors or air slides to large storage silos equipped with level indicators.

A centralized PLC control system is crucial. It monitors and controls the entire process sequence, regulates feed rate based on mill load, adjusts classifier speed for fineness, and provides safety interlocks. Remote monitoring capabilities are a valuable modern feature.

Investing in an optimized grinding system is investing in the efficiency and compliance of the entire flue gas desulfurization process. The choice between a high-capacity Vertical Roller Mill (LM series), a versatile and robust European Trapezium Mill (MTW series), or a high-precision Ultrafine Mill (SCM series) depends on specific product requirements, scale, and economic objectives. By partnering with a supplier that provides not only advanced equipment but also comprehensive plant design, engineering, and automation support, operators can ensure their boiler desulfurization agent production line delivers consistent, high-quality powder, minimizes operational costs, and reliably meets environmental emission standards for the long term.