December 29, 2025

Introduction

Calcite, a naturally occurring calcium carbonate mineral, is a cornerstone material for numerous industries including plastics, paints, coatings, paper, and construction. The value and performance of calcite in these applications are critically dependent on its particle size distribution, purity, and morphology. Therefore, selecting the appropriate grinding equipment and designing an efficient, integrated production plant are paramount for manufacturers aiming to achieve high-quality products, operational efficiency, and competitive advantage. This article delves into the core equipment for calcite processing, from coarse crushing to ultra-fine grinding, and outlines the principles for building a complete, optimized production line.

The Grinding Spectrum: From Coarse to Ultra-Fine

The transformation of raw calcite lumps into market-ready powder involves a multi-stage process, each requiring specialized machinery.

1. Primary and Secondary Crushing

Before fine grinding, raw calcite (often 0-200mm) must be reduced to a manageable feed size. Jaw crushers are typically used for primary crushing, followed by impact crushers or hammer mills for secondary reduction. A Hammer Mill is particularly effective for this stage, capable of producing a consistent 0-3mm product ideal for feeding into grinding mills. Its high capacity, compact design, and wear-resistant components ensure reliable pre-grinding with low operational costs.

2. Fine and Ultra-Fine Grinding – The Heart of the Process

This is where the final product specifications are achieved. The choice of mill depends on the target fineness, required capacity, and energy efficiency goals.

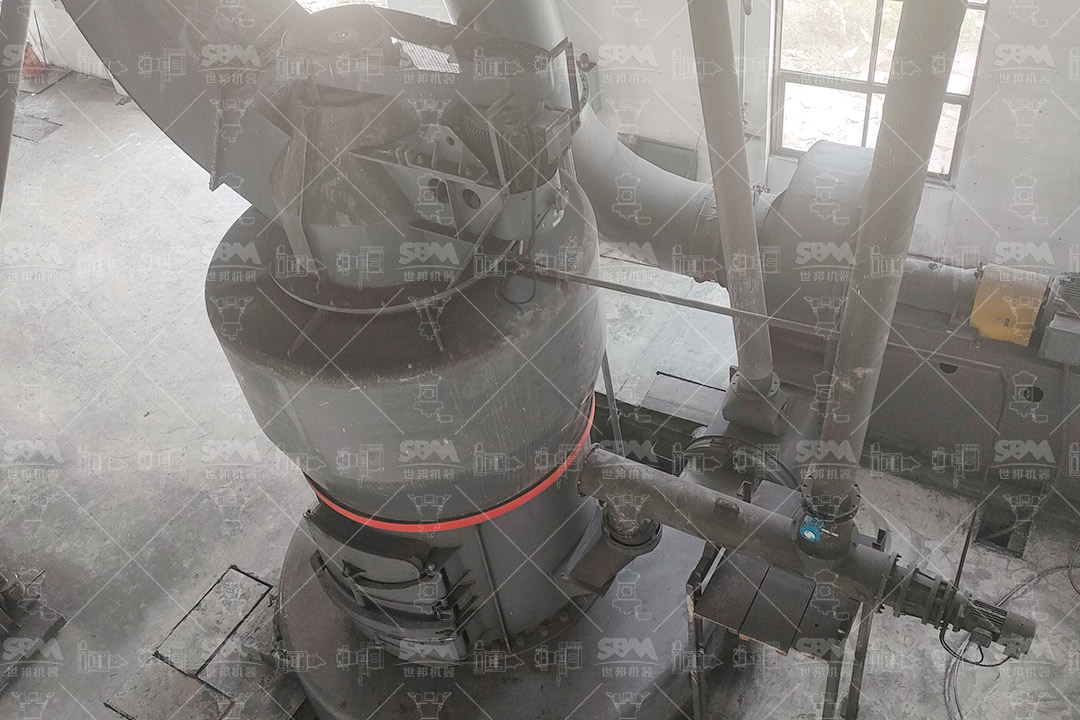

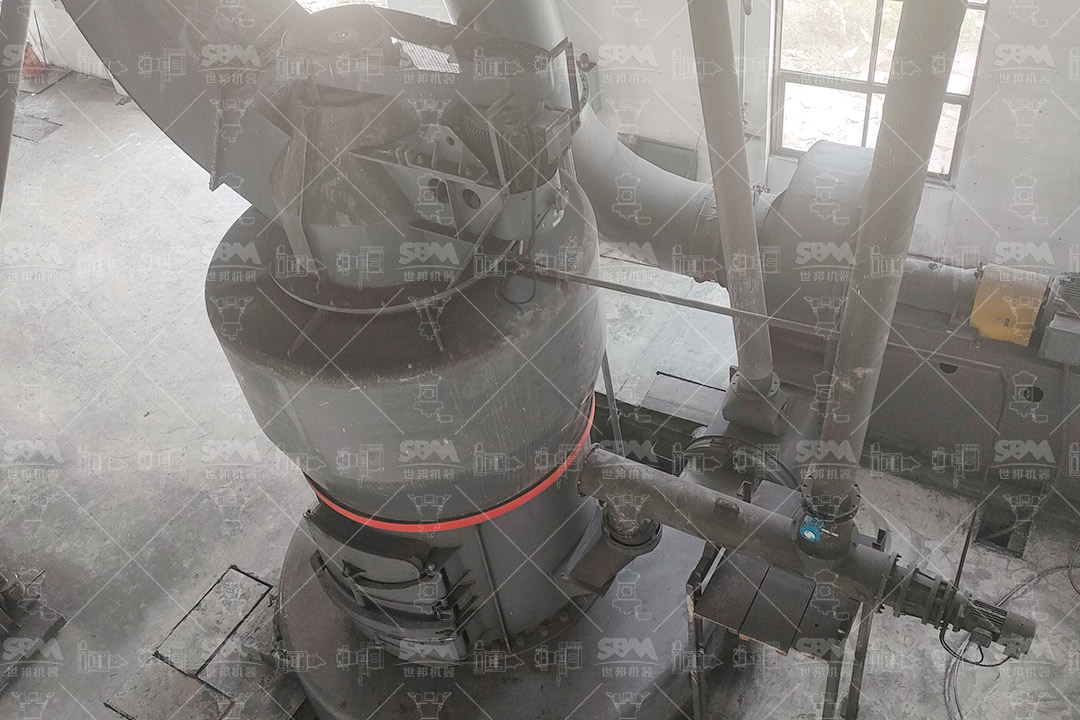

- For Coarse to Medium Fineness (30-325 mesh / 600-45μm): Mills like the MTW Series Trapezium Mill and MTM Series Medium-Speed Trapezium Mill excel. They offer robust construction, high throughput (3-45 TPH), and are known for their reliability and lower capital investment. The MTW series, with its curved air duct and integral transmission gear, stands out for its high transmission efficiency and reduced energy loss.

- For High-Capacity Fine Grinding (30-325 mesh): The LM Series Vertical Roller Mill is the industry benchmark for large-scale production (up to 250 TPH). Its integrated design combines grinding, drying, classifying, and conveying in a single unit, offering unparalleled energy savings (30-40% less than ball mills), significantly reduced footprint, and advanced automated control systems.

- For Ultra-Fine Grinding (325-2500 mesh / 45-5μm): This demanding application requires specialized technology. Here, the SCM Ultrafine Mill is a premier solution. Engineered to produce powders with a D97 fineness as fine as 5μm (2500 mesh), it represents the pinnacle of fine grinding technology. Its vertical turbine classifier ensures precise particle size cuts without coarse grain contamination, while its unique grinding chamber design with roller and ring made from special materials guarantees long service life and stable operation. Compared to traditional jet mills, the SCM series can double the production capacity while reducing energy consumption by 30%, making it an exceptionally efficient choice for high-value calcite products.

| Mill Type |

Target Fineness |

Key Advantages |

Typical Capacity Range |

Ideal Application |

| MTW Trapezium Mill |

30-325 mesh |

High efficiency, durable, cost-effective |

3 – 45 TPH |

Filler for plastics, paints, construction |

| LM Vertical Roller Mill |

30-325 mesh |

Extremely energy-efficient, large capacity, integrated system |

10 – 250 TPH |

Large-scale production of ground calcium carbonate (GCC) |

| SCM Ultrafine Mill |

325-2500 mesh |

Ultra-fine precision, high classification accuracy, energy-saving |

0.5 – 25 TPH |

High-end plastics, premium coatings, functional fillers |

Beyond the Mill: Essential Auxiliary Systems

A grinding mill is only as good as the system that supports it. A complete plant solution includes:

- Feeding System: Vibrating feeders and belt conveyors for consistent, controlled material supply.

- Classification System: Dynamic classifiers integrated with the mill or standalone air classifiers to ensure precise particle size cuts and improve mill efficiency by removing fines from the grinding circuit.

- Dust Collection & Product Collection: Pulse-jet baghouse dust collectors are essential for meeting environmental standards (emissions < 20mg/m³) and for product recovery. High-efficiency cyclones are also used in conjunction.

- Packaging & Storage: Automated packing machines and silos for bulk storage ensure product integrity and handling efficiency.

- Electrical & Control System: A centralized PLC-based control system allows for remote monitoring, automatic adjustment of operational parameters, and data logging for optimization and quality control.

Designing a Complete Calcite Powder Plant

The design of a turnkey plant must consider several factors:

- Raw Material Analysis: Hardness, moisture content, and feed size determine the selection of crushers and mill type.

- Product Specification: The required fineness, whiteness, and throughput are the primary drivers for mill and classifier selection.

- Plant Layout & Space: Integrated vertical mills save significant space. A logical material flow minimizes conveying distances and potential contamination.

- Energy Optimization: Selecting high-efficiency mills like the LM Vertical Mill or SCM Ultrafine Mill, and incorporating heat recovery systems (e.g., from the mill’s hot air) drastically reduce operational costs.

- Environmental Compliance: The plant must be designed as a closed, negative-pressure system with high-efficiency dust collectors and noise reduction measures (e.g., soundproof enclosures for mills).

Conclusion

The production of high-quality calcite powder is a sophisticated engineering challenge that extends beyond simply choosing a grinder. It requires a holistic approach that matches the right grinding technology—whether it’s the high-capacity LM Vertical Roller Mill for standard GCC or the precision-focused SCM Ultrafine Mill for premium ultrafine products—with robust auxiliary systems and intelligent plant design. By partnering with an equipment supplier that can provide not just machinery but complete plant solutions, including engineering, commissioning, and automation, calcite producers can build facilities that are efficient, sustainable, and capable of delivering consistent, high-value products to meet the exacting demands of the global market.