In the global effort to reduce emissions and combat air pollution, Flue Gas Desulfurization (FGD) systems have become a standard component in modern thermal power plants. Among various desulfurization technologies, the wet limestone-gypsum process stands out for its high efficiency, reliability, and cost-effectiveness. At the heart of this process lies a crucial preparatory step: the grinding of raw limestone into a fine, reactive powder. The quality, fineness, and production efficiency of this limestone powder directly determine the overall desulfurization rate, system stability, and operational economics. This article delves into the technical requirements for desulfurization limestone powder and explores the optimal grinding solutions, with a focus on recommending high-performance equipment for power plant applications.

Not all limestone powder is suitable for efficient SO₂ removal. The FGD process imposes specific demands on the feedstock:

Traditional grinding systems, such as ball mills or Raymond mills, have been used in the past but present significant drawbacks for modern, large-scale FGD requirements. Ball mills, while reliable, suffer from high energy consumption, significant noise, and a large footprint. Their product fineness control is also less precise, often resulting in a wider PSD. Older generation Raymond mills may struggle with achieving the required ultra-fine fineness (e.g., 2500 mesh for highly efficient systems) or lack the capacity and automation needed for integration into a smart power plant. These limitations necessitate the adoption of more advanced grinding technology.

To meet the stringent and efficient demands of contemporary power plants, several advanced milling technologies have been developed. The ideal choice often depends on the required fineness, capacity, and overall project economics.

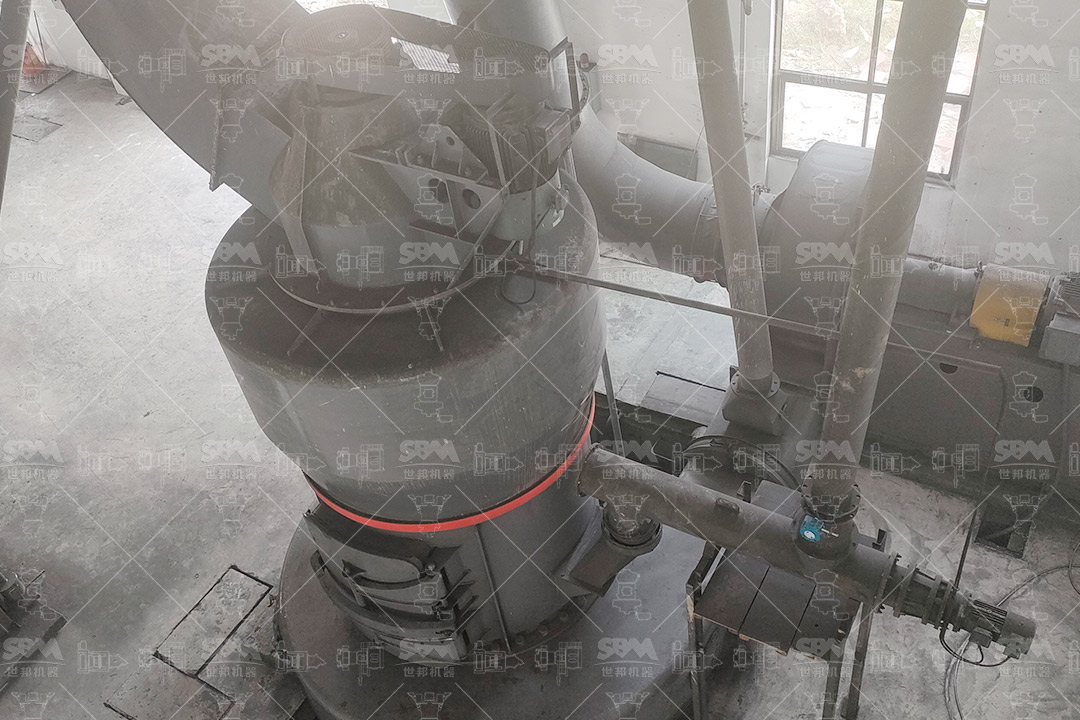

For large-scale power plants requiring high volumes of limestone powder (e.g., 30-250 t/h), the Vertical Roller Mill (VRM) is often the preferred solution. It integrates crushing, grinding, drying (if needed), and classification into a single, compact unit.

Recommended Product: LM Series Vertical Roller Mill

Our LM Series Vertical Roller Mill is engineered specifically for large-scale industrial mineral grinding, making it an outstanding choice for power plant desulfurization. Its core advantages align perfectly with FGD needs:

| Model | Grinding Table Diameter | Capacity (t/h) | Output Fineness | Main Motor Power (kW) |

|---|---|---|---|---|

| LM190K | Φ1900mm | 23-68 | 170-45μm (approx. 80-325 mesh) | 500 |

| LM220K | Φ2200mm | 36-105 | 170-45μm | 800 |

| LM280K | Φ2800mm | 50-170 | 170-45μm | 1250 |

When the FGD process design calls for extremely fine limestone powder (e.g., 800-2500 mesh) to maximize reaction kinetics and minimize slurry preparation issues, an ultrafine grinding mill is the necessary technology. These mills are designed to produce powders with a very narrow and fine particle size distribution.

Recommended Product: SCM Series Ultrafine Mill

For power plants aiming for the highest desulfurization rates or those processing limestone with slightly lower reactivity, our SCM Series Ultrafine Mill is the ideal specialist equipment. It excels in producing the superfine powders that guarantee exceptional SO₂ removal performance.

For medium to large power plants where the fineness requirement is firmly in the 30-325 mesh range and operational cost-effectiveness is a key driver, the latest generation of European Trapezium Mills offers an excellent balance.

Product Highlight: MTW Series European Trapezium Mill

Our MTW Series Mill incorporates numerous patented technological advancements, making it a robust and economical choice for standard FGD limestone grinding. Its advantages include an anti-wear shovel design, optimized arc air duct for reduced energy loss, and an integral bevel gear drive with up to 98% transmission efficiency. It is particularly suited for projects seeking high reliability and lower initial investment without compromising on the essential quality of 325-mesh powder.

Choosing the right grinding mill is a strategic decision that impacts the FGD system’s performance for decades. Here is a simplified guide:

In conclusion, the success of a power plant’s flue gas desulfurization system is fundamentally linked to the quality and efficiency of its limestone powder preparation. Moving beyond outdated grinding technologies to adopt advanced solutions like the LM Vertical Roller Mill or the SCM Ultrafine Mill is not just an equipment upgrade—it is an investment in environmental compliance, operational economy, and plant reliability. By partnering with a knowledgeable supplier and selecting the mill that precisely matches your technical and economic parameters, power plants can ensure their FGD systems operate at peak performance, contributing to cleaner air and sustainable energy production.