Particle size distribution (PSD) is a critical parameter in comminution processes that significantly influences the efficiency and performance of ball mill grinding operations. Understanding the relationship between PSD and grinding efficiency is essential for optimizing mineral processing plants, reducing energy consumption, and improving product quality. This comprehensive analysis explores the fundamental principles of particle size distribution and its direct impact on ball mill performance, while introducing advanced grinding solutions that address these challenges.

Particle size distribution refers to the relative amounts of particles present in a sample according to their size. In ball mill grinding operations, PSD affects multiple aspects of the process, including grinding kinetics, media wear, and energy consumption. The ideal PSD curve varies depending on the material being processed and the desired final product specifications.

Several PSD parameters directly influence ball mill performance:

| Parameter | Impact on Grinding Efficiency | Optimal Range |

|---|---|---|

| D50 (Median Size) | Affects grinding kinetics and energy consumption | Material dependent |

| D80 (80% Passing Size) | Influences classification efficiency | Critical for circuit balance |

| Span (Distribution Width) | Impacts product quality and downstream processes | Narrow for uniform products |

| Specific Surface Area | Directly related to grinding energy requirements | Process specific |

Ball mill grinding involves three primary mechanisms: impact, attrition, and abrasion. The particle size distribution within the mill directly affects which mechanism dominates and how efficiently each operates.

Coarse particles (typically >1mm) are primarily reduced through impact forces. When the mill contains an optimal proportion of coarse material, the grinding efficiency increases as the kinetic energy transfer from grinding media to particles becomes more effective. However, excessive coarse material can lead to overloading and reduced efficiency.

Intermediate-sized particles (100μm-1mm) undergo attrition grinding, where particles rub against each other and the mill lining. The presence of these particles creates a cushioning effect that can either protect finer particles from overgrinding or reduce grinding efficiency depending on their concentration.

Fine particles (<100μm) are generated through abrasion mechanisms. While necessary for product specification achievement, excessive fines can lead to cushioning, reduced impact efficiency, and increased energy consumption per unit of new surface area created.

Research and industrial experience have demonstrated that maintaining an optimal particle size distribution within the ball mill is crucial for maximizing grinding efficiency. The ideal PSD follows a first-order breakage function where the rate of breakage is proportional to the amount of material present in each size fraction.

Classification systems, whether internal (grate-discharge mills) or external (closed-circuit operations), play a vital role in maintaining optimal PSD. Efficient classification ensures that properly ground material is removed from the circuit while coarse material is returned for further grinding.

| Circuit Type | PSD Control Capability | Energy Efficiency | Product Quality |

|---|---|---|---|

| Open Circuit | Limited | Lower | Variable |

| Closed Circuit | Good | Higher | Consistent |

| Pre-classification | Excellent | Highest | Superior |

While traditional ball mills face challenges in maintaining optimal PSD, modern grinding technologies offer superior control over particle size distribution. Our SCM Ultrafine Mill represents a significant advancement in grinding technology, specifically designed to address PSD-related efficiency challenges.

The SCM Ultrafine Mill series achieves remarkable PSD control through its innovative design and advanced classification system. With an output fineness range of 325-2500 mesh (D97≤5μm) and processing capacity of 0.5-25 tons per hour, this mill consistently produces uniform particle distributions that maximize process efficiency.

Key features that enhance PSD control include:

The energy efficiency of the SCM Ultrafine Mill is particularly noteworthy, offering 30% lower energy consumption compared to conventional systems while doubling the capacity of jet mills. This efficiency is directly attributable to its superior PSD management capabilities.

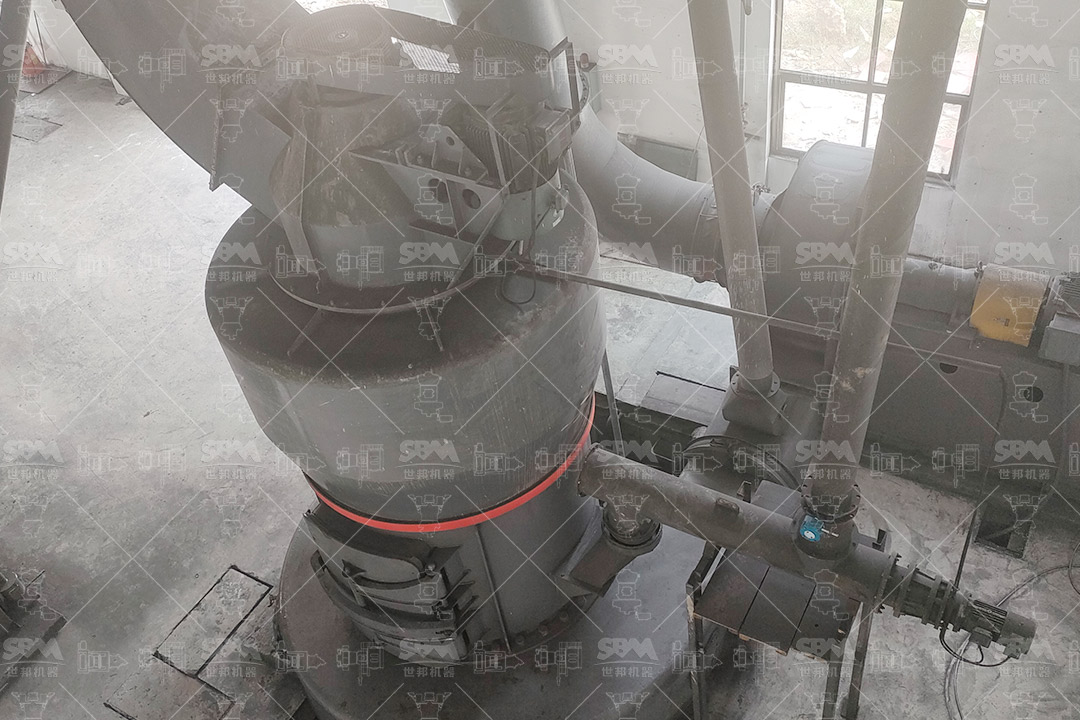

For applications requiring high throughput with consistent particle size distribution, our MTW Series Trapezium Mill offers exceptional performance. With processing capacities ranging from 3-45 tons per hour and output fineness of 30-325 mesh, this mill incorporates several innovative features for optimal PSD control:

The MTW Series demonstrates how proper mechanical design directly influences PSD stability and grinding efficiency, particularly in high-volume applications.

The relationship between PSD and grinding efficiency has been demonstrated across numerous industrial applications. In mineral processing operations, optimizing PSD has led to energy savings of 15-25% while improving product quality. Similarly, in cement production, proper PSD control has reduced specific energy consumption by 20-30% while enhancing product strength characteristics.

Successful implementation of PSD optimization strategies requires:

The future of grinding efficiency lies in advanced PSD monitoring and control technologies. Real-time particle size analyzers, machine learning algorithms for process optimization, and integrated grinding-classification systems represent the next frontier in comminution efficiency. Our grinding equipment is designed to integrate seamlessly with these emerging technologies, ensuring that our clients remain at the forefront of grinding efficiency.

Particle size distribution is not merely a product specification but a fundamental parameter that directly governs ball mill grinding efficiency. Understanding and controlling PSD throughout the grinding process enables significant improvements in energy efficiency, product quality, and operational costs. Advanced grinding technologies like our SCM Ultrafine Mill and MTW Series Trapezium Mill demonstrate how proper equipment selection and design can optimize PSD control, delivering substantial benefits across various industrial applications. As grinding technology continues to evolve, the relationship between PSD and efficiency will remain a central consideration in comminution circuit design and operation.