The manufacturing of high-purity electronic components demands exceptional precision in material processing, particularly when working with quartz. Quartz, with its excellent electrical insulation, thermal stability, and low thermal expansion, is a critical material in substrates, resonators, and insulating parts. The grinding process must achieve ultra-fine particle sizes with narrow distribution, maintain chemical purity, and prevent contamination. Selecting the appropriate grinding mill is paramount to meeting these stringent requirements, impacting product performance, yield, and overall cost-effectiveness. This guide provides a comprehensive analysis of the key factors and technologies involved in choosing a quartz grinding mill for electronic applications.

Not all quartz powder is suitable for electronic components. The material must meet specific criteria to ensure the reliability and functionality of the final product.

For most high-purity electronic applications, such as ceramic substrates or filler materials, the required fineness typically falls within the range of 325 mesh to 2500 mesh (approximately 45 μm down to 5 μm). A tight particle size distribution (PSD) is crucial. A wide PSD can lead to inconsistent packing density, uneven sintering in ceramics, and variable electrical properties. The D97 value—the particle size at which 97% of the powder is finer—is a key specification. Mills must reliably and consistently achieve the target D97 with minimal oversize particles.

Even trace amounts of metallic impurities (e.g., Fe, Al, Ca) can severely degrade the insulating properties and thermal stability of quartz components. The grinding mill must be constructed with materials that minimize wear and the subsequent introduction of contaminants. Ceramic-lined grinding chambers, high-chromium alloy rollers, and specialized wear-resistant steels are often employed to preserve material purity.

Quartz undergoes a phase transformation from alpha to beta quartz at around 573°C. Excessive heat generated during grinding can induce this transformation and cause micro-cracking, affecting the powder’s sintering behavior and final properties. Efficient cooling systems within the mill are essential to keep temperatures well below this critical point.

Different mill types operate on distinct principles, making them more or less suitable for the delicate task of processing electronic-grade quartz.

Principle: Utilizes a rotating cylinder filled with grinding media (balls) to crush and grind material via impact and attrition.

Pros: Simple design, high capacity, capable of very fine grinding.

Cons for Electronics: High risk of metallic contamination from grinding media and liner wear. Inefficient energy use, with significant energy lost as heat. Particle size distribution can be broad and difficult to control precisely. Generally not recommended for high-purity applications unless equipped with ceramic grinding media.

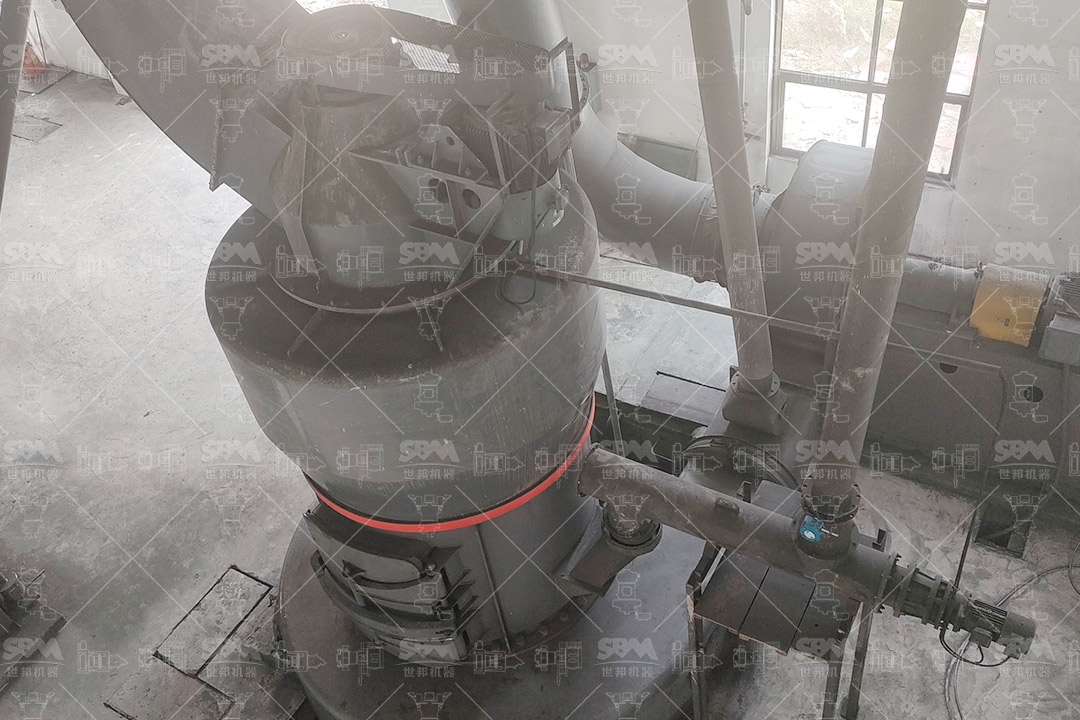

Principle: Material is ground between rotating rollers and a stationary grinding ring.

Pros: Reliable, well-established technology, good for coarse to medium-fine grinding (30-325 mesh).

Cons for Electronics: Typically limited to a lower fineness (around 325 mesh) which may not be sufficient for advanced components. Potential for contamination from mechanical parts like rollers and rings, though less than ball mills. The MTW Series Trapezium Mill, for instance, offers improved wear-resistant designs and efficient curved air channels, making it a robust option for preliminary size reduction where the highest fineness is not required.

Principle: Material is ground between a rotating table and rollers pressed against it.

Pros: Highly efficient due to its bed-compaction grinding principle, lower energy consumption, integrated drying, grinding, and classification. The LM Series Vertical Roller Mill is known for its集约化设计 (intensive design), reducing footprint by 50%, and its low operating costs, with energy consumption 30-40% lower than ball mill systems.

Cons for Electronics: Can be less effective for achieving the ultra-fine end of the spectrum (consistently below 10μm) compared to specialized ultra-fine mills. Requires careful selection of wear parts to maintain purity.

Principle: Combines mechanical grinding with an integrated, highly precise air classifier. Grinding forces are primarily applied through roller pressure.

Pros: Specifically designed for the 5-45μm (325-2500 mesh) range. They produce a very narrow particle size distribution. Advanced models feature ceramic grinding components to ensure purity and efficient cooling systems.

Cons: Generally higher capital cost than more basic mills, and may have a lower single-unit capacity compared to large vertical roller mills.

| Mill Type | Typical Output Fineness | Contamination Risk | Energy Efficiency | Suitability for High-Purity Quartz |

|---|---|---|---|---|

| Ball Mill | 0.074-0.8mm | High | Low | Low |

| Raymond Mill (MTW) | 30-325 mesh | Medium | Medium | Medium (for pre-grinding) |

| Vertical Roller Mill (LM) | 30-600 mesh | Medium-Low | High | Medium-High |

| Ultrafine Mill (SCM/LUM) | 325-2500 mesh | Low | High | High |

When evaluating specific mill models, focus on the following technical and operational aspects.

For producers targeting the high-value market of electronic components, the SCM Ultrafine Mill stands out as a premier choice. It is engineered specifically for the challenges of producing high-purity, ultra-fine powders.

Why the SCM Series is Ideal for Electronic-Grade Quartz:

Model Selection Example: For a medium-scale production line requiring high-purity quartz powder around 1250 mesh (10μm), the SCM1000 model is an excellent fit, offering a processing capacity of 1.0-8.5 tons per hour with a main motor power of 132kW.

For operations where the primary requirement is not the absolute ultra-fine range but high efficiency and reliability in the coarse to medium-fine grinding stage, the MTW Series Trapezium Mill is a robust and advanced choice. It is perfectly suited for pre-processing quartz before a final pass in an ultrafine mill or for applications where fineness down to 325 mesh (45μm) is sufficient.

Key Advantages of the MTW Series:

Model Selection Example: The MTW138Z model, with a capacity of 6-17 tons per hour and the ability to produce powder from 10 to 325 mesh, is a workhorse for efficient initial size reduction of quartz materials.

Selecting the right quartz grinding mill for high-purity electronic components is a strategic decision that directly impacts product quality and manufacturing viability. The choice hinges on a clear understanding of the required particle size, purity levels, and production scale. While traditional mills like ball mills pose a high contamination risk, and Raymond mills are limited in fineness, advanced technologies like the SCM Ultrafine Mill and the MTW Trapezium Mill offer targeted solutions. For the most demanding applications requiring D97 values of 5μm and stringent purity, the SCM Series provides an unmatched combination of precision, efficiency, and contamination control, making it the recommended technology for manufacturers committed to excellence in the electronics industry.