The selection of an appropriate talc grinding plant is a critical decision for paint and coating manufacturers. Talc, as a functional filler and extender, significantly influences product properties such as opacity, viscosity, gloss control, and durability. The grinding process determines the final particle size distribution, which directly impacts these characteristics. This comprehensive guide will help you navigate the complex decision-making process to select the optimal grinding solution for your specific production requirements.

Talc (hydrated magnesium silicate) possesses unique properties that make it valuable in paint and coating formulations. Its platy structure provides barrier properties, while its softness (1 on Mohs scale) makes it relatively easy to grind. However, achieving the desired particle size distribution while maintaining the platelet structure requires specialized grinding equipment.

Key considerations for talc grinding in paint applications include:

| Paint Type | Recommended Talc Fineness | Typical Applications |

|---|---|---|

| Industrial Coatings | 325-1250 mesh (45-10μm) | Corrosion resistance, sag control |

| Architectural Paints | 400-800 mesh (38-19μm) | Sheen control, touch-up |

| High-Performance Coatings | 1250-2500 mesh (10-5μm) | Gloss control, barrier properties |

| Primers | 200-400 mesh (75-38μm) | Filling, sandability |

Your grinding plant selection must align with your production volume needs. Consider both current requirements and future expansion plans. Equipment capacity ranges from small batch processors (0.5-5 ton/h) to large continuous production systems (25+ ton/h).

The required particle size distribution dictates the type of grinding technology needed. Coarser products (45-325 mesh) can be processed with standard mills, while ultrafine applications (1250-2500 mesh) require specialized equipment with advanced classification systems.

Grinding operations typically account for significant energy consumption in paint production. Modern grinding systems offer substantial energy savings through optimized designs, efficient classification, and intelligent control systems.

Evaluate your available space, ceiling height, and infrastructure capabilities. Some grinding systems offer compact, integrated designs that minimize footprint, while others may require substantial space for ancillary equipment.

Consider the total cost of ownership, including wear part replacement frequency, maintenance requirements, and operational labor costs. Advanced designs with durable components and easy maintenance access can significantly reduce long-term costs.

For applications requiring very fine talc powders (325-2500 mesh), ultrafine grinding mills offer precise particle size control with high efficiency. These systems typically incorporate advanced classification technology to ensure narrow particle size distribution.

Our SCM Ultrafine Mill represents the pinnacle of ultrafine grinding technology for talc applications. With output fineness ranging from 325-2500 mesh (D97≤5μm) and capacity from 0.5-25 ton/h depending on model, this system delivers exceptional performance for high-value paint and coating applications.

| Model | Processing Capacity (ton/h) | Main Motor Power | Output Fineness |

|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 kW | 325-2500 mesh |

| SCM900 | 0.8-6.5 | 90 kW | 325-2500 mesh |

| SCM1000 | 1.0-8.5 | 132 kW | 325-2500 mesh |

| SCM1250 | 2.5-14 | 185 kW | 325-2500 mesh |

| SCM1680 | 5.0-25 | 315 kW | 325-2500 mesh |

The SCM series features vertical turbine classifiers for precise particle size cuts, special material rollers and grinding rings for extended service life, and energy consumption that’s 30% lower than conventional jet mills while delivering twice the output capacity.

For standard paint and coating applications requiring talc in the 30-325 mesh range, medium-fine grinding mills offer an optimal balance of performance, efficiency, and cost-effectiveness.

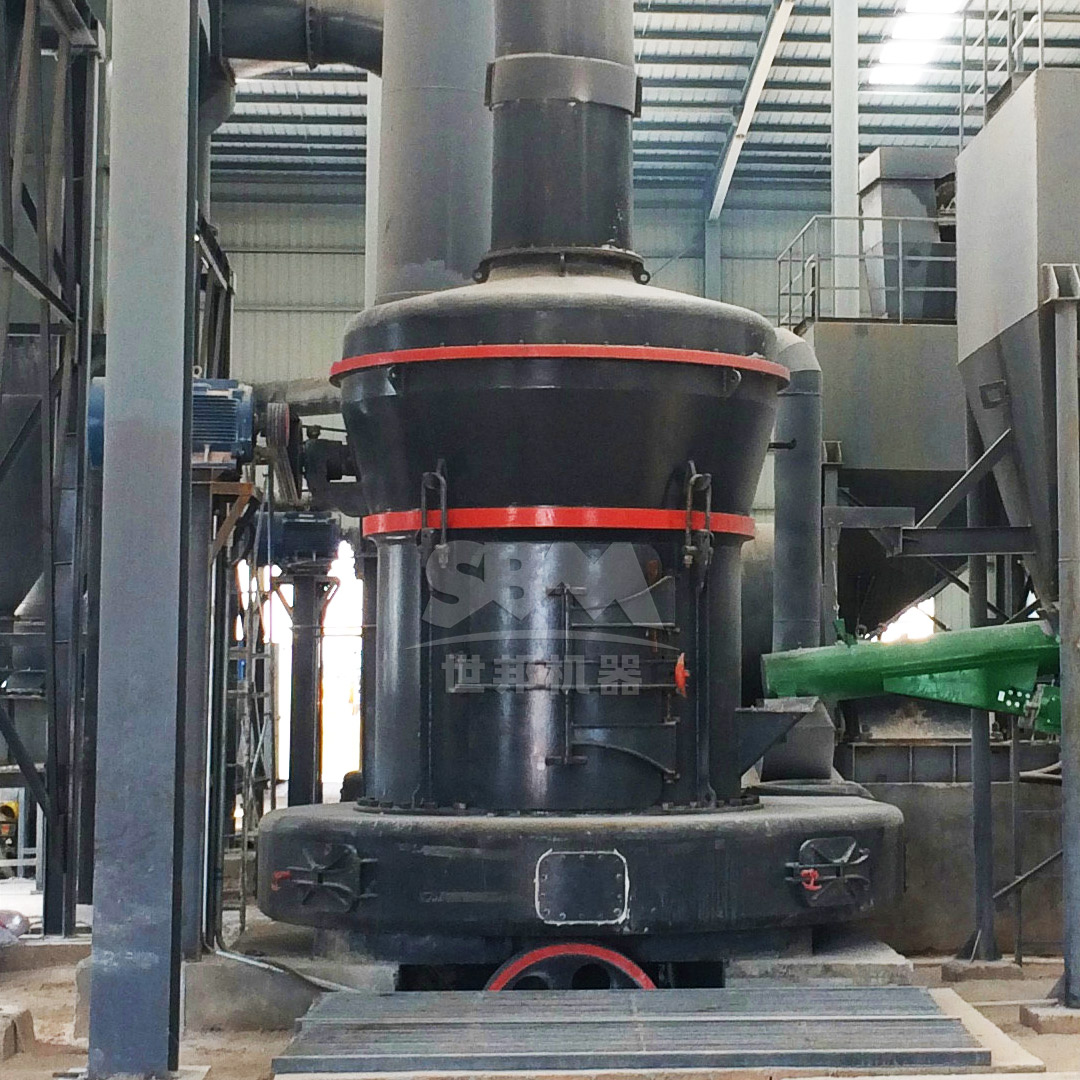

Our MTW Series Trapezium Mill provides excellent solutions for standard talc grinding requirements. With output fineness from 30-325 mesh and capacity ranging from 3-45 ton/h, this robust system handles feed materials up to 50mm with high efficiency and reliability.

Key advantages of the MTW series include wear-resistant shovel design that reduces maintenance costs, curved air channel optimization that improves transmission efficiency, and cone gear integral transmission achieving 98% transmission efficiency. The system’s durable construction and optimized wear protection make it ideal for continuous talc processing operations.

Vertical roller mills offer high capacity processing with integrated drying capabilities, making them suitable for talc with varying moisture content. Their compact design and high efficiency make them attractive for large-scale operations.

Traditional ball mills remain relevant for certain talc applications, particularly where wide particle size distribution is acceptable. Modern ball mills offer improved efficiency through advanced lining designs and drive systems.

Proper material feeding is essential for consistent grinding performance. Vibratory feeders, screw conveyors, and belt feeders must be selected based on material characteristics and production rate requirements.

Air classifiers are critical for controlling particle size distribution. Options include static classifiers, dynamic classifiers, and high-efficiency cyclones, each with specific advantages for different applications.

Modern grinding plants must meet strict environmental standards. Pulse jet baghouse filters typically provide the high collection efficiency required for talc applications, with emissions well below regulatory limits.

Consider the complete material flow from raw material receiving through finished product packaging. Pneumatic conveying systems, silos, and automated packaging lines should integrate seamlessly with the grinding system.

| Technology | Fineness Range | Capacity Range | Energy Efficiency | Capital Cost | Best Applications |

|---|---|---|---|---|---|

| Ultrafine Mills (SCM) | 325-2500 mesh | 0.5-25 t/h | High | Medium-High | High-performance coatings |

| Trapezium Mills (MTW) | 30-325 mesh | 3-45 t/h | High | Medium | Standard industrial coatings |

| Vertical Roller Mills | 30-600 mesh | 3-250 t/h | Very High | High | Large volume production |

| Ball Mills | 0.074-0.8mm | 0.65-450 t/h | Medium | Low-Medium | Cost-sensitive applications |

A major coatings manufacturer recently upgraded their talc grinding system to our SCM1000 Ultrafine Mill to meet demanding specifications for automotive coatings. The previous system struggled to achieve consistent 1250 mesh fineness with acceptable production rates.

After implementation, the manufacturer achieved:

The vertical turbine classification system proved particularly valuable for maintaining the platelet structure of talc, which enhanced the barrier properties in the final coating formulations.

The talc grinding industry continues to evolve with several emerging trends:

Advanced control systems with real-time monitoring, predictive maintenance, and remote operation capabilities are becoming standard in modern grinding plants. These systems optimize performance, reduce downtime, and improve product consistency.

New designs focus on reducing specific energy consumption through optimized grinding geometries, improved classification efficiency, and waste heat recovery systems.

Equipment designs increasingly consider environmental impact through reduced emissions, lower noise levels, and compatibility with alternative energy sources.

Selecting the right talc grinding plant requires careful consideration of your specific product requirements, production volume, quality standards, and economic factors. The SCM Ultrafine Mill stands out for high-value applications requiring fine and ultrafine talc powders with precise particle size control, while the MTW Series Trapezium Mill offers robust performance for standard coating applications.

By understanding the capabilities of different grinding technologies and matching them to your specific needs, you can optimize your paint and coating production for quality, efficiency, and profitability. Consult with experienced grinding equipment suppliers to conduct trials and develop the optimal solution for your operation.