Kaolin, also known as china clay, is a naturally occurring hydrated aluminum silicate mineral that has become increasingly important in industrial catalyst support production. The unique properties of kaolin, including its chemical inertness, thermal stability, and specific surface area characteristics, make it an ideal material for supporting various catalytic agents in chemical processes. The production of high-quality catalyst supports requires precise control over particle size distribution, purity, and morphological characteristics, which can only be achieved through advanced grinding and processing technologies.

In catalyst manufacturing, the particle size distribution of the support material directly impacts the catalytic efficiency, selectivity, and longevity of the final product. Finely ground kaolin with controlled particle size distribution provides optimal surface area for catalyst deposition, ensuring uniform dispersion of active catalytic components and maximizing reaction efficiency. The grinding process must achieve consistent particle size while maintaining the structural integrity of the kaolin particles to ensure mechanical strength in catalytic applications.

The transformation of raw kaolin into suitable catalyst support material involves multiple processing stages, each requiring specialized equipment to achieve the desired product characteristics. The primary objectives in kaolin processing for catalyst supports include achieving specific surface area targets, controlling particle morphology, eliminating impurities, and ensuring thermal stability.

| Parameter | Target Range | Importance in Catalyst Support |

|---|---|---|

| Particle Size (D97) | 5-45 μm | Optimal surface area for catalyst loading |

| Specific Surface Area | 10-50 m²/g | Determines catalyst dispersion efficiency |

| Particle Morphology | Platelet structure preservation | Enhances mechanical strength |

| Chemical Purity | >98% | Prevents catalyst poisoning |

| Thermal Stability | Up to 1000°C | Ensures performance in high-temperature reactions |

Selecting the appropriate grinding equipment is critical for achieving the precise particle size distribution and morphological characteristics required for high-performance catalyst supports. Different grinding technologies offer varying advantages depending on the specific requirements of the catalyst application.

For applications requiring extremely fine kaolin powders with particle sizes in the range of 5-45 microns, specialized ultrafine grinding equipment is essential. Our SCM Ultrafine Mill represents an ideal solution for catalyst support production, offering precise control over particle size distribution with output fineness ranging from 325 to 2500 mesh (D97 ≤ 5μm). The mill’s advanced vertical turbine classification system ensures accurate particle size切割 without coarse powder contamination, resulting in uniform product quality essential for consistent catalyst performance.

The SCM series demonstrates remarkable efficiency with capacity reaching twice that of jet mills while reducing energy consumption by 30%. This combination of high precision and energy efficiency makes it particularly suitable for large-scale catalyst support manufacturing operations. The intelligent control system automatically monitors and adjusts product fineness, ensuring consistent quality throughout production cycles.

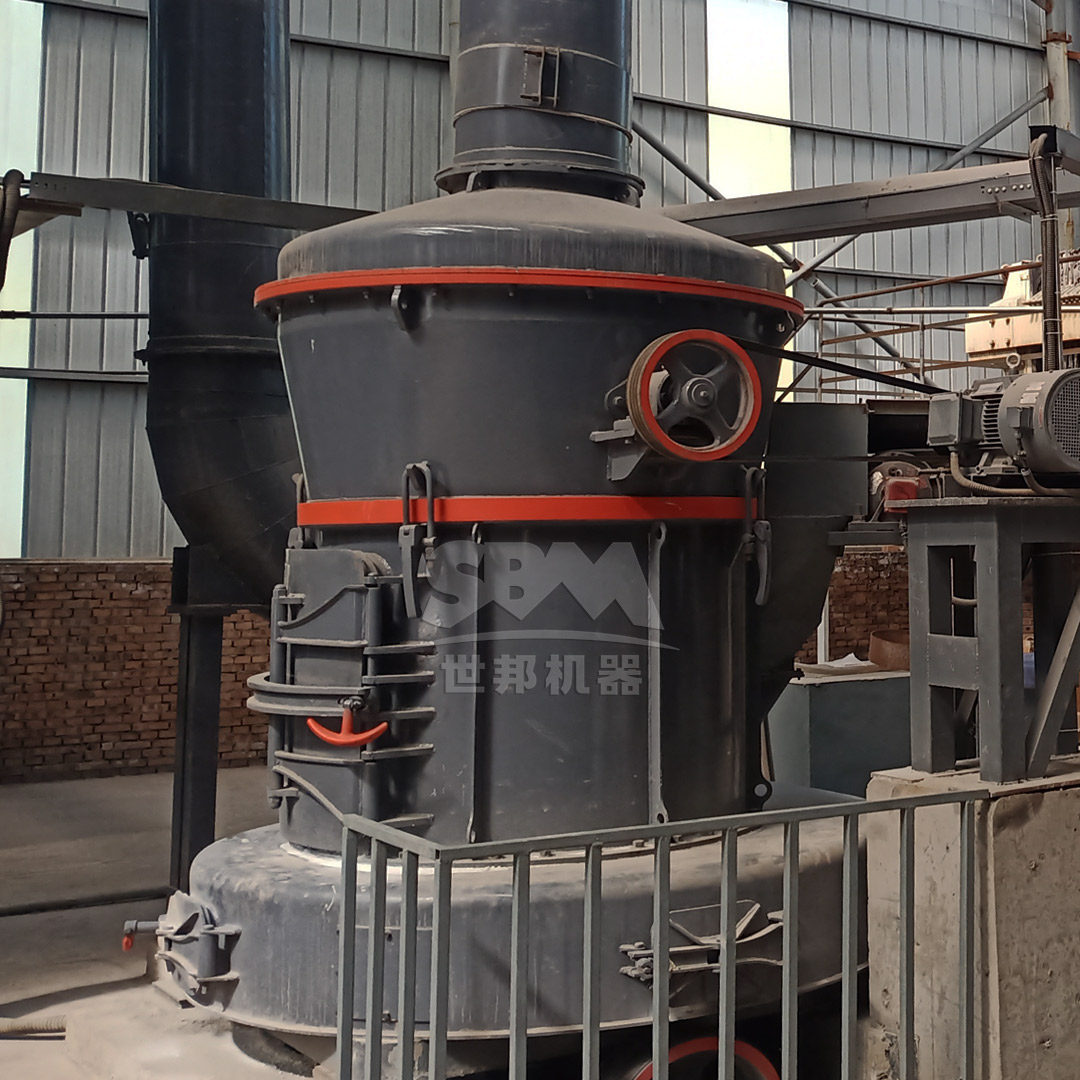

For applications requiring medium to fine kaolin powders in the 45-325 mesh range, our MTW Series Trapezium Mill provides an optimal balance of processing capacity and energy efficiency. With throughput capacities ranging from 3 to 45 tons per hour depending on model selection, the MTW series is well-suited for high-volume catalyst support production facilities.

The MTW mill incorporates several advanced features specifically beneficial for kaolin processing, including anti-wear shovel design that significantly reduces maintenance costs and curved air duct optimization that minimizes energy loss during material transport. The integrated cone gear transmission system achieves 98% transmission efficiency while saving installation space and reducing overall project costs.

A complete kaolin processing plant for catalyst support production involves multiple interconnected systems working in harmony to transform raw material into finished product. Proper plant design considers material handling, grinding efficiency, classification accuracy, and environmental compliance.

A typical integrated kaolin processing plant includes raw material storage and handling systems, primary crushing equipment, drying systems, grinding mills, classification equipment, product collection systems, and packaging facilities. Each component must be carefully selected and integrated to ensure optimal performance and product quality.

For primary crushing applications where raw kaolin needs to be reduced from large chunks to manageable sizes, our hammer mill series offers excellent performance with input sizes up to 40mm and output controlled to 0-3mm, providing ideal feed material for subsequent fine grinding operations.

Modern kaolin processing plants incorporate advanced automation systems to maintain consistent product quality and optimize operational efficiency. Real-time monitoring of key parameters including particle size distribution, moisture content, and production rate ensures that the final product meets the stringent specifications required for catalyst support applications.

Producing kaolin-based catalyst supports requires careful consideration of several technical factors beyond simple particle size reduction. The grinding process must preserve the inherent platelet structure of kaolin while achieving the desired surface area and pore structure characteristics.

Unlike many other minerals where complete particle destruction is desired, kaolin grinding for catalyst applications must maintain the platelet structure that contributes to the mechanical strength and surface characteristics of the final support material. Our grinding equipment is specifically designed to achieve this balance through controlled grinding forces and optimized operational parameters.

Catalyst supports demand exceptionally high purity levels to prevent catalyst poisoning and ensure consistent performance. Our grinding systems incorporate specialized designs to minimize contamination from wear parts, utilizing advanced materials for grinding elements and implementing effective sealing systems to prevent external contamination.

The selection of grinding equipment for kaolin processing must consider not only technical performance but also economic viability and environmental compliance. Modern grinding technologies offer significant advantages in both areas compared to traditional approaches.

Advanced grinding systems like our SCM Ultrafine Mill and MTW Trapezium Mill incorporate multiple energy-saving features that significantly reduce operating costs. These include optimized grinding mechanisms, efficient classification systems, and intelligent control systems that adjust operational parameters in real-time to minimize energy consumption while maintaining product quality.

Modern kaolin grinding plants must meet stringent environmental regulations regarding dust emissions and noise levels. Our equipment incorporates advanced pulse dust collection systems with efficiency exceeding international standards and noise reduction technologies that maintain operational noise below 75dB, ensuring compliance with workplace safety and environmental regulations.

| Equipment Model | Capacity Range (t/h) | Final Fineness | Recommended Application |

|---|---|---|---|

| SCM800 Ultrafine Mill | 0.5-4.5 | 325-2500 mesh | High-purity catalyst supports |

| SCM1680 Ultrafine Mill | 5.0-25 | 325-2500 mesh | Large-scale support production |

| MTW110 Trapezium Mill | 3-9 | 30-325 mesh | General purpose catalyst supports |

| MTW215G Trapezium Mill | 15-45 | 30-325 mesh | High-volume industrial production |

The field of catalyst support production continues to evolve, with increasing demands for specialized kaolin products with tailored properties. Future developments in grinding technology will focus on even greater precision in particle size control, enhanced energy efficiency, and integration with digital technologies for improved process optimization.

The integration of Industry 4.0 technologies into kaolin grinding operations enables real-time optimization of process parameters, predictive maintenance, and enhanced quality control. Our grinding equipment is designed with compatibility for these advanced digital technologies, providing a foundation for future smart manufacturing implementations.

As catalyst applications become more specialized, the demand for customized kaolin supports with specific properties continues to grow. Our flexible grinding systems can be configured to produce tailored products meeting unique customer requirements, supported by comprehensive technical services to ensure optimal performance in specific applications.

In conclusion, the production of high-quality kaolin-based catalyst supports requires sophisticated grinding technology capable of delivering precise particle size control while preserving the essential morphological characteristics of the material. Our SCM Ultrafine Mill and MTW Trapezium Mill series offer proven solutions for these demanding applications, combining technical performance with economic efficiency and environmental compliance.