Limestone plays a pivotal role in cement manufacturing as a primary raw material, contributing to both the chemical composition and physical properties of the final product. This article explores the technical advantages of limestone utilization and introduces advanced grinding solutions from our product line to optimize production efficiency.

As the primary source of calcium carbonate (CaCO3), limestone undergoes calcination to form lime (CaO), the essential component of cement clinker. The optimal limestone composition should contain:

| Component | Ideal Content (%) | Function |

|---|---|---|

| CaCO3 | ≥90 | Primary clinker formation |

| MgCO3 | <5 | Prevent excessive expansion |

| SiO2 | 1-5 | Moderate C2S formation |

1. Energy Efficiency: Limestone’s lower calcination temperature (900°C vs. 1400°C for clay) reduces thermal energy consumption by 15-20%.

2. Grindability: With Bond Work Index of 10-12 kWh/t, limestone requires 30% less grinding energy than alternative materials.

3. Quality Enhancement: High-purity limestone improves early strength development through optimized C3S formation.

To maximize limestone’s potential, our SCM Ultrafine Mill series delivers unparalleled performance:

| Model | Capacity (t/h) | Power (kW) | Footprint (m²) |

|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 15 |

| SCM1680 | 5.0-25 | 315 | 45 |

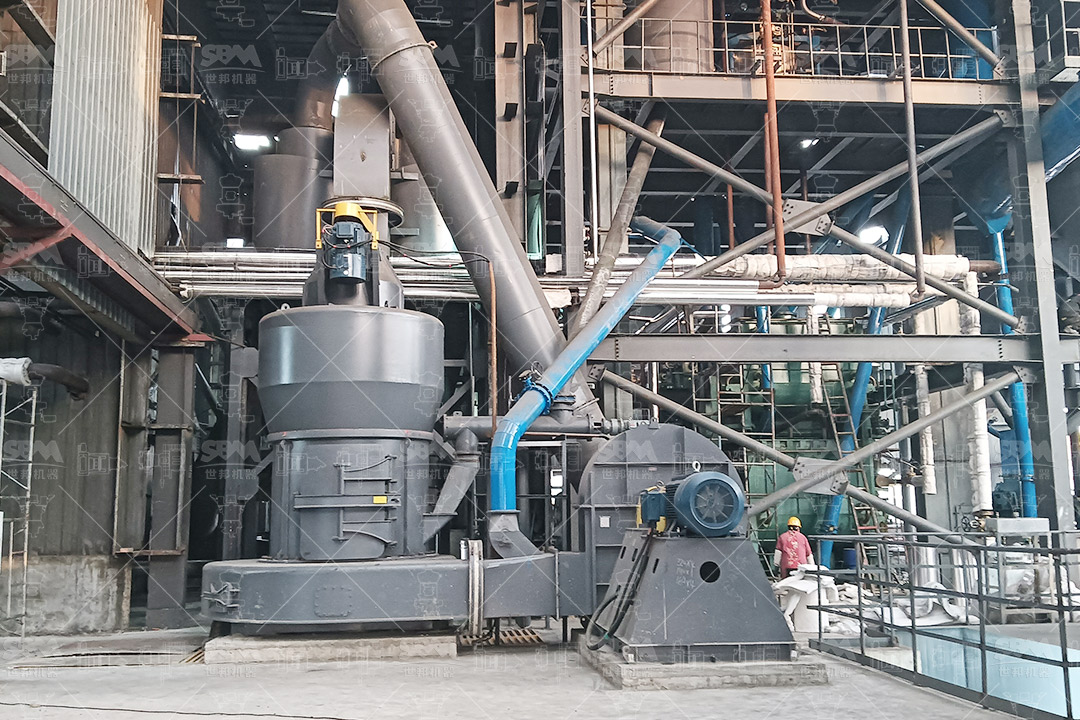

For large-scale operations, our MTW Series Trapezium Mill offers robust performance with 3-45 t/h capacity and innovative curved air duct design that reduces energy loss by 18%.

Modern limestone processing with our equipment achieves:

Strategic limestone utilization combined with advanced grinding technology from our SCM and MTW series can reduce cement production costs by up to 25% while improving product quality. Contact our technical team for customized limestone grinding solutions.