The mineral processing industry stands at a critical juncture, where the dual demands of operational efficiency and environmental sustainability are driving unprecedented technological innovation. Traditional grinding methods, often characterized by high energy consumption and significant environmental footprint, are being systematically replaced by advanced systems that deliver superior performance while minimizing ecological impact. This article explores the latest breakthroughs in mineral grinding technology, with particular focus on efficiency enhancements and sustainability achievements that are reshaping industry standards.

Modern mineral grinding operations face increasing pressure to optimize energy utilization while maintaining or improving throughput rates. The conventional ball mill, while reliable, typically operates at energy efficiency levels below 10%, with the majority of input power converted to heat and noise rather than productive grinding work. Recent technological advancements have dramatically improved this equation through several key innovations.

The integration of artificial intelligence and machine learning algorithms has revolutionized grinding process optimization. Modern mills employ sophisticated sensors that continuously monitor critical parameters including particle size distribution, mill load, and power consumption. These systems automatically adjust operational settings in real-time to maintain optimal grinding conditions, typically achieving energy savings of 15-25% compared to manually controlled operations.

Precise particle size classification represents another area of significant advancement. High-efficiency classifiers utilizing vertical turbine technology now achieve unprecedented separation accuracy, ensuring that only properly sized particles exit the grinding circuit. This eliminates the energy waste associated with over-grinding and reduces circulating loads, further enhancing overall system efficiency.

| Technology | Energy Saving | Throughput Improvement | Maintenance Reduction |

|---|---|---|---|

| Traditional Ball Mill | Baseline | Baseline | Baseline |

| Advanced Vertical Mills | 30-40% | 15-25% | 40-50% |

| Ultrafine Grinding Systems | 25-35% | 20-30% | 30-40% |

Beyond pure efficiency considerations, environmental sustainability has emerged as a critical driver of innovation in mineral grinding. Regulatory pressures, corporate sustainability commitments, and community expectations have collectively pushed equipment manufacturers to develop solutions that significantly reduce the environmental impact of grinding operations.

Modern grinding systems incorporate advanced pulse-jet dust collection technology that achieves filtration efficiencies exceeding 99.9%. These systems maintain dust emission levels below 20mg/m³, well under international regulatory standards. The implementation of full negative pressure operation ensures zero dust leakage throughout the grinding process, protecting both workers and the surrounding environment.

Noise pollution has traditionally been a significant concern in grinding operations. Contemporary designs address this through integrated acoustic insulation chambers, vibration damping systems, and optimized mechanical configurations that collectively reduce operational noise to 75-80dB(A). This represents a reduction of 10-15dB compared to conventional equipment, creating safer working conditions and minimizing community disturbance.

While this article focuses primarily on dry grinding systems, it’s worth noting that water conservation represents another critical sustainability consideration. Dry grinding technologies eliminate water consumption entirely in many applications, addressing a significant environmental concern in water-scarce regions where mineral processing often occurs.

Among the most significant recent developments in grinding technology is the SCM Series Ultrafine Mill, which represents a quantum leap in fine and ultrafine grinding capabilities. This system achieves output fineness ranging from 325 to 2500 mesh (D97≤5μm) while delivering throughput rates of 0.5-25 tons per hour depending on specific model configuration.

The SCM Ultrafine Mill incorporates several groundbreaking technological features that contribute to its exceptional performance:

At the heart of the SCM’s performance is its advanced vertical turbine classification system, which provides precise particle size control without coarse powder contamination. This technology enables the production of consistently uniform fine powders that meet the most stringent quality requirements for advanced industrial applications.

The SCM system demonstrates remarkable energy efficiency, achieving throughput rates approximately double that of jet mills while reducing energy consumption by 30%. This performance stems from optimized grinding geometry, intelligent control systems that automatically adjust to maintain target particle size, and reduced internal circulation loads.

Through the use of special wear-resistant materials for rollers and grinding rings, the SCM Ultrafine Mill extends component life by several multiples compared to conventional designs. The innovative bearing-free screw grinding chamber further enhances operational stability and reduces maintenance requirements, contributing to higher overall equipment availability.

| Model | Capacity (ton/h) | Main Motor Power (kW) | Output Fineness (mesh) |

|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 325-2500 |

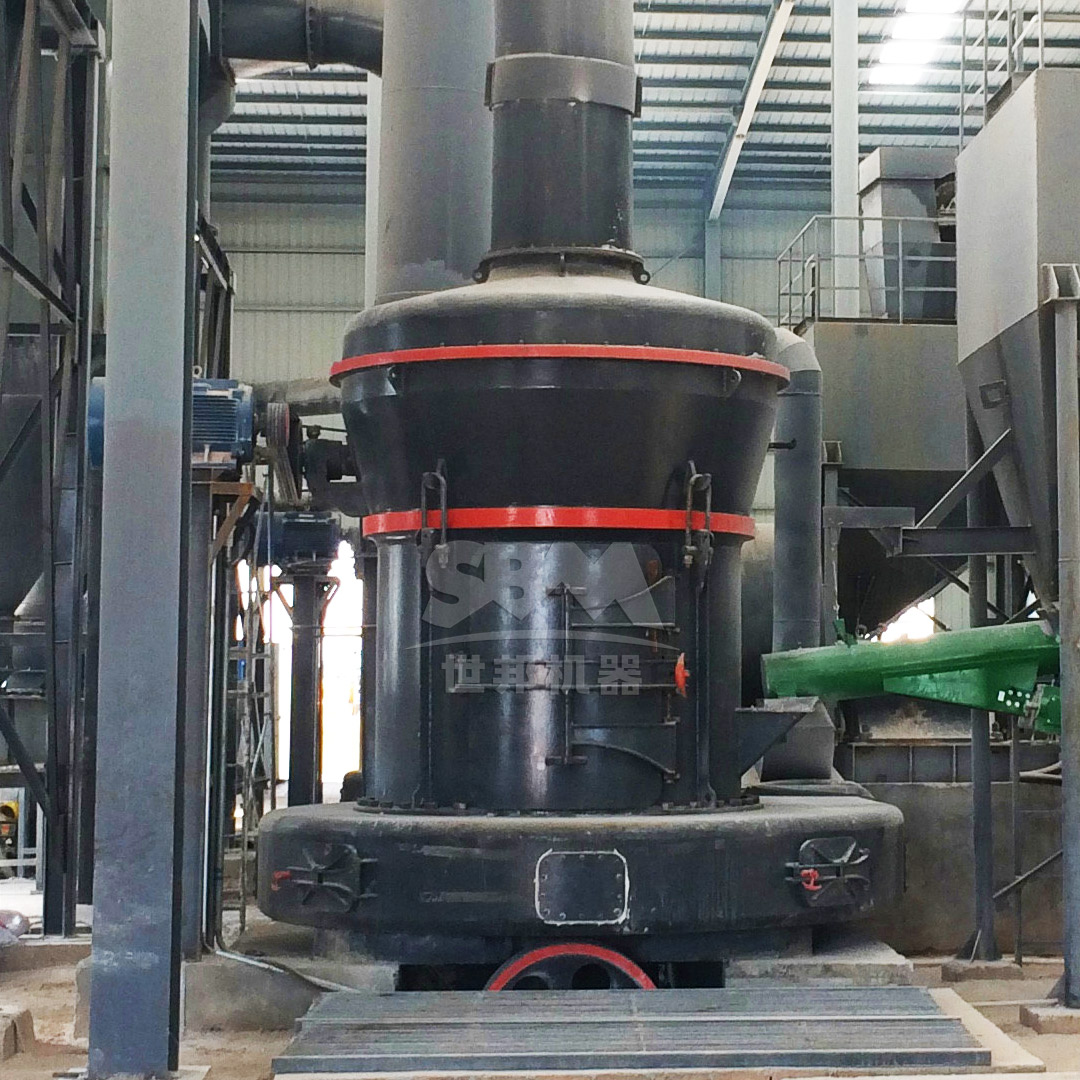

For applications requiring medium to fine grinding in the range of 30-325 mesh, the MTW Series Trapezium Mill offers an optimal balance of performance, efficiency, and operational flexibility. With capacity ranging from 3-45 tons per hour and feed size up to 50mm, this system addresses a broad spectrum of mineral processing requirements.

The MTW Series incorporates several distinctive technological advantages:

The MTW utilizes an integrated bevel gear transmission system that achieves remarkable 98% transmission efficiency. This innovative approach not only reduces energy losses but also saves installation space and lowers overall project costs compared to conventional drive systems.

The curved air channel design significantly reduces airflow resistance and energy consumption while high-strength protective plates extend service life in high-wear environments. Combined with the wear-resistant volute structure that eliminates flow obstruction, these features enhance overall classification efficiency and reduce maintenance costs by approximately 30%.

The innovative anti-wear shovel blade design incorporates composite shovel plates that lower maintenance costs while curved geometry extends roller service life. This system automatically compensates for component wear, maintaining consistent performance throughout the maintenance cycle.

The evolution of mineral grinding technology continues at an accelerating pace, with several promising developments emerging on the horizon. These include the integration of digital twin technology for predictive maintenance, the application of advanced materials science to develop next-generation wear components, and the implementation of hybrid energy systems that further reduce carbon footprint.

The next frontier in grinding technology involves full digital integration, where grinding systems become nodes in interconnected smart factories. Real-time data analytics, predictive maintenance algorithms, and remote operational capabilities will further enhance efficiency, reduce downtime, and optimize resource utilization.

Research into novel composite materials and specialized surface treatments promises to extend component life even further while reducing friction and energy consumption. These developments will particularly benefit high-wear applications where maintenance costs traditionally represent a significant operational expense.

The mineral grinding industry is undergoing a profound transformation driven by the dual imperatives of efficiency and sustainability. Technologies such as the SCM Ultrafine Mill and MTW Series Trapezium Mill exemplify this evolution, delivering step-change improvements in performance while significantly reducing environmental impact. As these and other innovative systems become increasingly adopted across the industry, they collectively contribute to a more sustainable and economically viable future for mineral processing worldwide. The continued convergence of mechanical innovation, digital intelligence, and environmental stewardship promises even greater advances in the years ahead, establishing new benchmarks for what constitutes world-class grinding performance.