Lignite, often referred to as brown coal, represents a significant global energy resource. Its efficient utilization, however, hinges on advanced processing technologies to convert this low-rank coal into a high-value, consistent, and reactive powder. The core of any lignite beneficiation or direct combustion system is the grinding mill plant. Selecting the right grinding equipment is paramount, impacting final product quality, energy consumption, operational costs, and environmental compliance. This article delves into the complete solutions for lignite powder production, focusing on the critical role of modern grinding technology and presenting optimal equipment choices for various application scales and fineness requirements.

Lignite presents unique challenges for grinding equipment due to its high inherent moisture content, lower hardness compared to bituminous coal or anthracite, and potential abrasiveness from mineral matter. An ideal grinding system must handle these characteristics efficiently:

The evolution of grinding technology has provided several pathways for lignite processing. The choice depends on the target fineness, required capacity, and whether the process is standalone or integrated with drying.

For medium to large-scale lignite powder production, especially where raw coal moisture is significant, Vertical Roller Mills (VRMs) are the dominant technology. Their integrated design allows simultaneous grinding and drying using hot gases, making them exceptionally efficient.

Key Advantages for Lignite:

For such demanding applications, our LM Series Vertical Roller Mill stands out as a premier solution. Engineered for minerals, coal, and slag, its design is perfectly suited for lignite. The system operates under fully sealed negative pressure, ensuring no dust leakage—a critical factor for both safety and environmental standards. Its intelligent control system allows for expert-level automation, enabling real-time monitoring and adjustment of grinding pressure, classifier speed, and gas temperature to maintain optimal product fineness (typically targeting 30-325 mesh, or 600-45μm) and moisture content despite variations in feed material.

| Model | Grinding Table Diameter | Capacity (t/h)* | Main Motor Power | Target Fineness |

|---|---|---|---|---|

| LM150K | Φ1500mm | 13-38 | 280 kW | 170-40μm |

| LM190K | Φ1900mm | 23-68 | 500 kW | 170-40μm |

| LM220K | Φ2200mm | 36-105 | 800 kW | 170-45μm |

*Capacity varies based on lignite characteristics and product fineness.

For applications where lignite is pre-dried or has naturally low moisture, trapezium mills offer an excellent balance of precision, efficiency, and reliability. These mills excel in producing finely controlled particle sizes with uniform distribution.

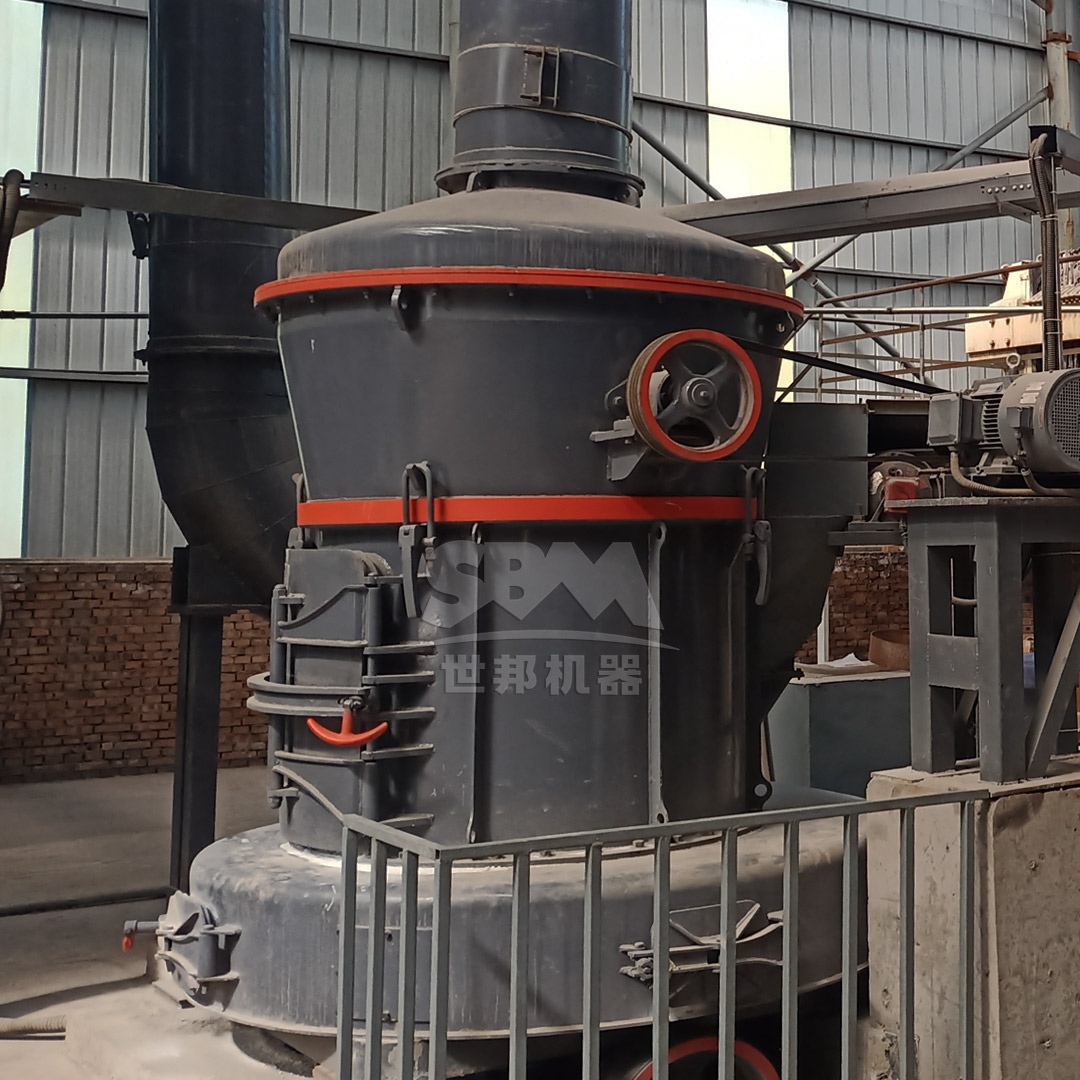

Our MTW Series European Trapezium Mill incorporates several patented advancements that make it ideal for producing high-quality lignite powder. Its curved shovel blade design minimizes wear and extends component life when handling abrasive materials. The integral bevel gear drive achieves a remarkable 98% transmission efficiency, directly contributing to lower operational costs. Furthermore, the optimized arc air duct and wear-resistant volute structure ensure stable airflow and high classification efficiency, producing consistent powder in the range of 30-325 mesh (600-45μm). Models like the MTW175G and MTW215G are particularly well-suited for medium to high-capacity lignite grinding lines.

While most combustion applications require medium fineness, certain advanced utilization paths for lignite—such as slurry fuels or chemical feedstock—may demand ultrafine powders (below 45μm or 325 mesh). For these specialized requirements, advanced pulverizing technology is necessary.

Our SCM Series Ultrafine Mill is engineered to meet this challenge. It utilizes a unique grinding chamber design and a high-precision vertical turbine classifier to produce powders from 325 to 2500 mesh (45-5μm). The multi-layer grinding ring and roller system applies progressive crushing force, ensuring high efficiency with energy consumption up to 30% lower than jet mills of comparable output. For lignite-derived products requiring extreme fineness and uniformity, the SCM Series provides a reliable and economical solution.

A grinding mill is the heart of the plant, but a complete solution requires synergistic auxiliary systems.

The journey from raw lignite to a high-performance powder demands more than just a machine; it requires a holistic plant solution based on deep material understanding and proven technology. Success hinges on selecting equipment that offers not only the required capacity and fineness but also durability, energy efficiency, and environmental integrity.

Our portfolio, from the high-capacity, drying-integrated LM Vertical Roller Mill to the precision-engineered MTW European Trapezium Mill, provides tailored answers for every stage of lignite valorization. By leveraging our expertise in complete plant design and our range of robust grinding technologies, producers can build efficient, reliable, and future-proof lignite powder production facilities that maximize resource value while minimizing operational and environmental costs.