Petroleum coke (petcoke) is a carbonaceous solid derived from oil refinery coker units or other cracking processes. As a valuable carbon material, it finds extensive applications in aluminum anodes, steel production, fuel sources, and various industrial processes. The quality of ground petcoke significantly impacts its performance in these applications, making the selection of appropriate grinding equipment crucial for achieving optimal particle size distribution, purity, and processing efficiency.

The grinding process for petroleum coke presents unique challenges due to its abrasive nature, variable hardness, and potential for contamination. Proper milling ensures consistent product quality while maximizing operational efficiency and minimizing energy consumption. This article explores the technical requirements for petroleum coke grinding and highlights advanced milling solutions that deliver superior performance in carbon material processing.

Effective petroleum coke processing demands equipment capable of handling specific material characteristics while meeting stringent quality standards. Key considerations include:

Different applications require precise particle size distributions. Aluminum anode production typically needs material ground to 100-325 mesh, while certain carbon products may require ultrafine grinding down to 2500 mesh (5μm). Consistent fineness control ensures predictable performance in downstream processes.

Petroleum coke applications often demand minimal iron contamination, which can adversely affect electrical conductivity and chemical properties. Grinding systems must incorporate designs that prevent metal-to-metal contact or utilize specialized wear materials that don’t contaminate the product.

Petcoke grinding generates significant heat, which can degrade material quality or create safety hazards. Effective cooling systems and thermal controls are essential for maintaining product integrity.

With grinding operations accounting for substantial energy consumption in carbon material production, mills must optimize power usage while maintaining throughput and product quality.

Modern grinding technology offers several approaches to petroleum coke processing, each with distinct advantages for specific applications and production requirements.

For applications requiring ultrafine petroleum coke powders, the SCM Ultrafine Mill represents an optimal solution. This advanced grinding system delivers exceptional performance with output fineness ranging from 325 to 2500 mesh (D97≤5μm), making it ideal for high-value carbon products where precise particle size control is critical.

The SCM series incorporates several technological innovations specifically beneficial for petroleum coke processing:

| Model | Capacity (ton/h) | Main Motor Power (kW) | Feed Size (mm) | Output Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | ≤20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | ≤20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | ≤20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | ≤20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | ≤20 | 325-2500 |

The working principle involves main motor-driven rotation of triple-layer grinding rings, with material dispersed into the grinding path by centrifugal force. After roller compression crushing, material undergoes progressive grinding through multiple layers, with final powder collection accomplished by cyclone collector and pulse dust removal systems.

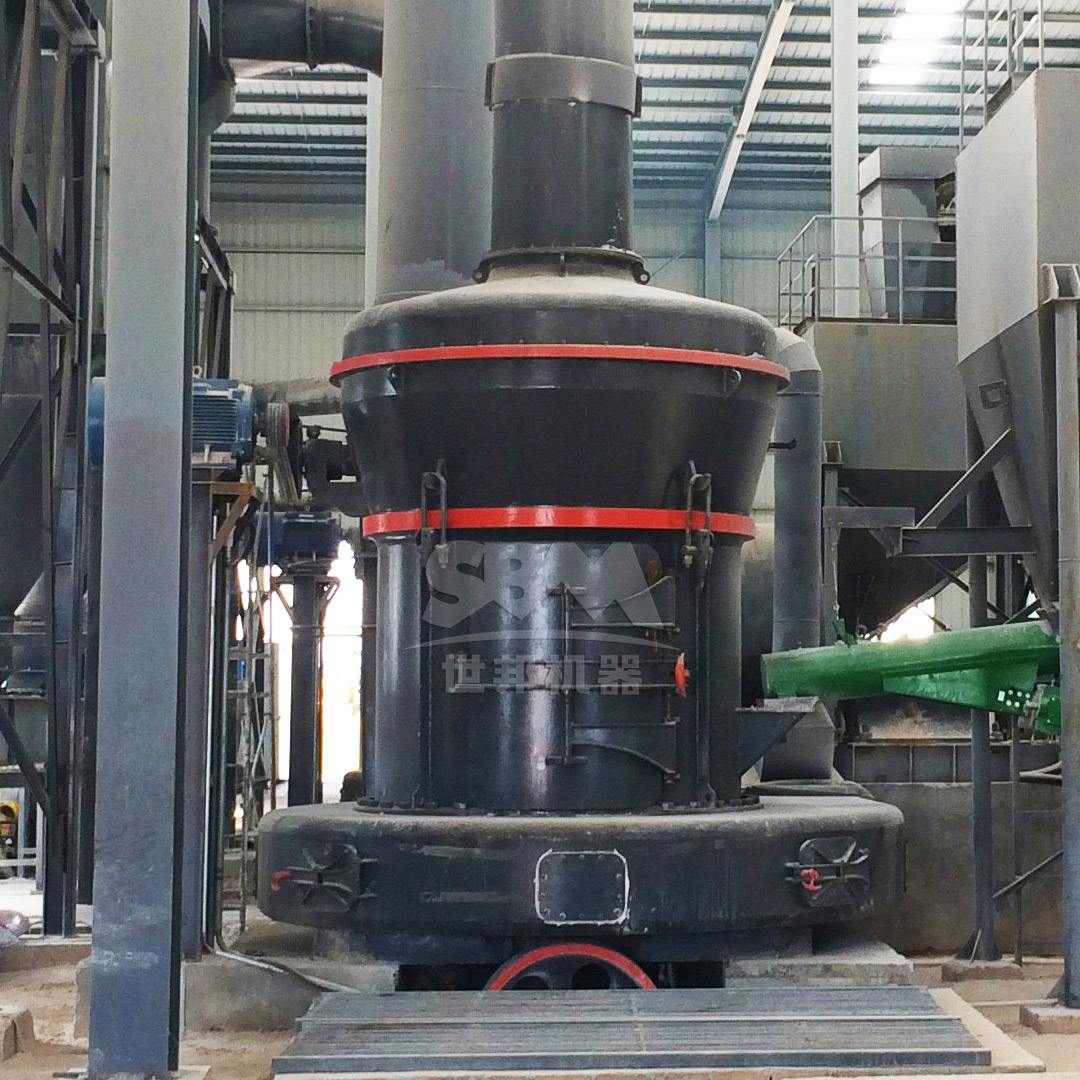

For large-scale petroleum coke processing operations requiring high throughput with medium fineness, the MTW Series Trapezium Mill offers an efficient solution. With capacity ranging from 3 to 45 tons per hour and output fineness from 30 to 325 mesh, this mill excels in production environments where volume and consistency are paramount.

Key features beneficial for petroleum coke grinding include:

| Model | Capacity (ton/h) | Main Motor Power (kW) | Feed Size (mm) | Output Fineness (mesh) |

|---|---|---|---|---|

| MTW110 | 3-9 | 55 | <30 | 10-325 |

| MTW138Z | 6-17 | 90 | <35 | 10-325 |

| MTW175G | 9.5-25 | 160 | <40 | 10-325 |

| MTW215G | 15-45 | 280 | <50 | 10-325 |

The operational principle involves the main motor driving grinding rollers to revolve around the central axis while rotating themselves to generate centrifugal force. Shovel blades throw material between the grinding ring and roller to form a material layer, achieving efficient crushing through extrusion, with the classification system precisely controlling final particle size.

Beyond equipment selection, several operational factors significantly impact the efficiency and quality of petroleum coke grinding processes.

Proper sizing of feed material is essential for optimal mill performance. For larger petroleum coke chunks (up to 50mm), preliminary crushing using equipment like hammer mills can improve grinding efficiency and reduce wear on fine grinding components. The Hammer Mill (0-3mm) offers an excellent pre-crushing solution with throughput from 8-70 tons per hour, depending on model selection.

Petroleum coke moisture content affects grinding efficiency and product handling. Optimal moisture levels typically range between 1-5%, with higher moisture causing material agglomeration and reduced throughput. Integrated drying systems or pre-processing steps may be necessary for high-moisture feedstocks.

Modern grinding systems incorporate advanced control technologies that optimize operation based on real-time conditions. Features like automatic pressure adjustment, wear compensation, and fineness control ensure consistent product quality while reducing operator intervention.

Effective dust control is critical in petroleum coke processing due to material combustibility and workplace safety requirements. Integrated pulse-jet dust collectors with efficiency exceeding international standards, combined with soundproofing designs maintaining noise levels below 75dB, address both environmental and operational concerns.

Selecting the appropriate grinding technology requires careful consideration of production requirements, product specifications, and economic factors. The following comparison highlights key differences between mill types for petroleum coke applications:

| Mill Type | Optimal Fineness Range | Capacity Range | Energy Efficiency | Best Application |

|---|---|---|---|---|

| SCM Ultrafine Mill | 325-2500 mesh | 0.5-25 t/h | High | Ultrafine high-value products |

| MTW Trapezium Mill | 30-325 mesh | 3-45 t/h | High | High-volume standard products |

| Ball Mill | 0.074-0.8mm | 0.65-450 t/h | Medium | General purpose, high capacity |

| LUM Vertical Mill | 325-2500 mesh | 1.6-15 t/h | High | Ultrafine with compact footprint |

For most petroleum coke applications, the SCM Ultrafine Mill and MTW Trapezium Mill represent the optimal balance of performance, efficiency, and product quality. The SCM series excels in premium applications requiring precise ultrafine powders, while the MTW series delivers superior throughput for standard fineness requirements.

The total cost of ownership for petroleum coke grinding equipment extends beyond initial investment to include operational expenses, maintenance requirements, and product quality impacts.

Advanced mills like the SCM and MTW series achieve 30-50% energy savings compared to conventional technologies, significantly reducing operating costs over equipment lifetime. With grinding operations typically accounting for a substantial portion of facility energy usage, these efficiencies deliver meaningful economic benefits.

Component lifespan directly impacts operating costs and production availability. The specialized materials used in SCM and MTW mills extend wear part life significantly, with grinding rollers and rings lasting several times longer than conventional designs. Reduced maintenance frequency translates to higher operational availability and lower labor costs.

Superior particle size control and consistency enable premium product positioning in certain markets. The ability to precisely target specific fineness requirements with minimal contamination allows producers to access higher-value market segments, potentially justifying equipment investment through enhanced product pricing.

The evolution of grinding technology continues to address emerging requirements in petroleum coke processing, with several trends shaping equipment development:

Integration of IoT technologies, predictive maintenance algorithms, and remote monitoring capabilities enhances operational efficiency while reducing unplanned downtime. Modern mills increasingly incorporate sophisticated control systems that optimize performance based on real-time operating conditions.

Continued focus on reducing environmental impact drives development of even more efficient dust collection systems, noise reduction technologies, and energy recovery options. The latest mill designs achieve emissions levels below 20mg/m³ while maintaining operational performance.

Modular designs and quick-change components enable faster product transitions and easier maintenance, supporting the trend toward smaller batch sizes and customized products without sacrificing efficiency.

Selecting the appropriate grinding technology is critical for optimizing petroleum coke processing operations. The SCM Ultrafine Mill and MTW Series Trapezium Mill represent advanced solutions that address the specific challenges of carbon material grinding, delivering superior efficiency, product quality, and operational reliability. By matching equipment capabilities to production requirements, processors can achieve optimal economic and technical performance in their petroleum coke grinding operations.

As market demands evolve toward higher quality specifications and greater operational efficiency, continued innovation in grinding technology will further enhance the value proposition of advanced milling systems. The integration of digital controls, improved wear materials, and enhanced classification technologies positions these mills as long-term solutions for petroleum coke processors seeking competitive advantage through superior product quality and operational excellence.