In today’s competitive industrial landscape, grinding operations face increasing pressure to optimize efficiency while minimizing waste generation. The traditional approach to material processing often results in significant energy consumption, excessive material loss, and environmental concerns. This comprehensive analysis explores advanced waste reduction strategies that not only enhance operational efficiency but also contribute to sustainable manufacturing practices. By implementing modern grinding technologies and optimized processes, companies can achieve substantial cost savings while reducing their environmental footprint.

Grinding operations generate waste through multiple channels, each requiring specific mitigation strategies. The primary sources include:

Traditional grinding equipment often operates with outdated technology, consuming excessive power while delivering suboptimal performance. Energy waste typically accounts for 40-60% of total operational costs in conventional grinding systems.

Inefficient particle size control leads to over-grinding, generating fines that cannot be utilized in downstream processes. Additionally, improper classification results in product contamination and reduced quality.

Conventional grinding media and components experience rapid deterioration, generating metallic waste and requiring frequent replacement. This not only increases operational costs but also creates disposal challenges.

Dust generation, noise pollution, and thermal emissions represent significant environmental concerns that require advanced control technologies.

Modern grinding equipment incorporates sophisticated features specifically designed to minimize waste generation while maximizing productivity. The selection of appropriate technology depends on material characteristics, required product specifications, and production scale.

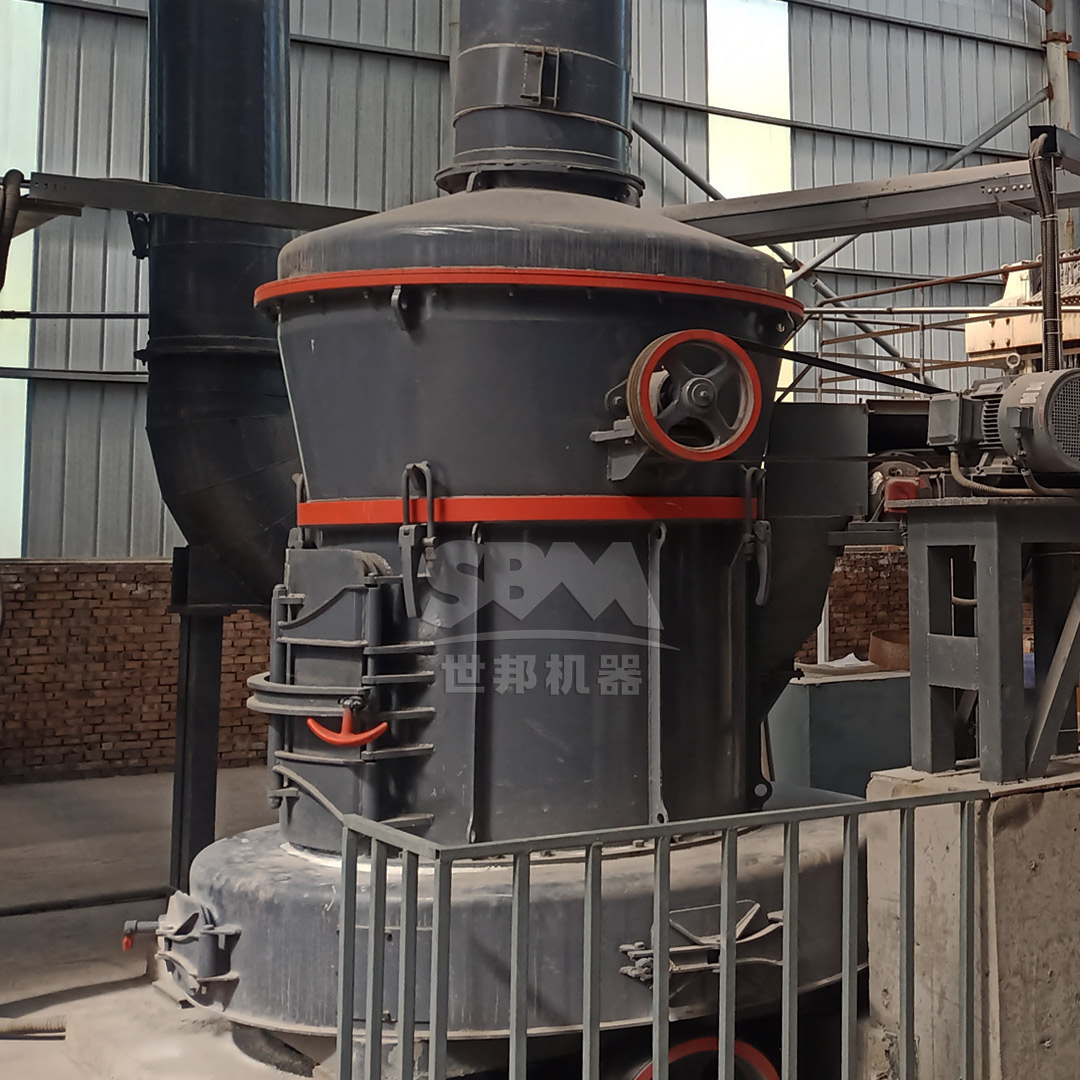

For applications requiring extremely fine powders with precise particle size distribution, advanced ultrafine grinding systems offer significant advantages. The SCM Ultrafine Mill represents a breakthrough in fine grinding technology, delivering exceptional performance while minimizing waste generation.

Key features that contribute to waste reduction include:

The SCM Ultrafine Mill achieves remarkable performance metrics, including energy consumption reductions of up to 30% compared to conventional jet mills, while doubling production capacity. With output fineness ranging from 325 to 2500 mesh (D97 ≤ 5μm) and processing capacities from 0.5 to 25 tons per hour, this technology provides versatile solutions across multiple industries.

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Output Fineness (mesh) |

|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 325-2500 |

For applications requiring medium to fine grinding with high throughput, the MTW Series Trapezium Mill offers an optimal balance of performance and efficiency. This advanced grinding system incorporates multiple waste-reduction features:

The MTW Series processes materials with input sizes up to 50mm, delivering output fineness from 30 to 325 mesh with capacities ranging from 3 to 45 tons per hour. The combination of advanced features results in maintenance cost reductions of up to 30% compared to conventional grinding systems.

Beyond equipment selection, operational practices play a crucial role in waste minimization. Implementing comprehensive process optimization strategies can yield additional efficiency improvements.

Thorough material characterization before grinding enables optimal equipment configuration and parameter settings. Key assessment parameters include:

Advanced control systems continuously monitor and adjust grinding parameters to maintain optimal conditions. Real-time adjustments include:

Regular maintenance prevents unexpected downtime and ensures consistent performance. Key maintenance practices include:

Modern grinding operations must address environmental regulations while pursuing sustainability objectives. Advanced grinding technologies incorporate multiple features to support these goals.

Integrated dust collection systems capture particulate matter with efficiency exceeding international standards. The SCM Ultrafine Mill’s pulse dust collector achieves filtration efficiency greater than 99.9%, ensuring compliance with stringent environmental regulations.

Advanced acoustic engineering minimizes noise pollution through multiple approaches:

Heat recovery from process air and cooling systems can be utilized for pre-drying applications, reducing overall energy consumption by 15-25%.

Implementing advanced grinding technologies requires capital investment, but delivers substantial returns through multiple channels.

The combination of reduced energy consumption, lower maintenance costs, and extended component lifespan typically generates payback periods of 12-24 months. Specific savings include:

| Cost Category | Traditional System | Advanced System | Reduction |

|---|---|---|---|

| Energy Consumption | 100% | 70% | 30% |

| Maintenance Costs | 100% | 70% | 30% |

| Component Replacement | 100% | 50% | 50% |

| Downtime Costs | 100% | 60% | 40% |

Beyond direct cost savings, advanced grinding systems deliver additional value through:

Successful implementation of waste reduction strategies requires a structured approach encompassing technology selection, process optimization, and continuous improvement.

Comprehensive evaluation of current operations identifies improvement opportunities:

Matching grinding technology to specific application requirements ensures optimal performance:

Ongoing monitoring and optimization maintain performance improvements:

The implementation of advanced grinding technologies and optimized operational practices delivers substantial benefits in waste reduction, cost savings, and environmental performance. Technologies such as the SCM Ultrafine Mill and MTW Trapezium Mill incorporate sophisticated features specifically designed to minimize waste generation while maximizing efficiency. By adopting a comprehensive approach that combines appropriate equipment selection, process optimization, and continuous improvement, grinding operations can achieve significant competitive advantages while contributing to sustainable industrial development. The transition to advanced grinding systems represents not only an economic opportunity but also an environmental imperative in today’s resource-constrained world.