The ceramic industry relies heavily on the quality and consistency of its raw materials, with feldspar standing as one of the most critical components in both body and glaze formulations. The particle size distribution of milled feldspar directly influences key ceramic properties such as sintering behavior, vitrification temperature, mechanical strength, and final surface finish. Traditional milling equipment often struggles to achieve the narrow particle size distributions and high surface areas required for advanced ceramic applications, leading to process inefficiencies and variable product quality. This article explores the technological advancements in ultrafine grinding, specifically focusing on how modern mills optimize feldspar processing for superior ceramic production.

Feldspar minerals (primarily potassium, sodium, and calcium aluminosilicates) serve as vital fluxes in ceramic manufacturing. In ceramic bodies, feldspar promotes vitrification during firing, reducing porosity and enhancing mechanical strength. In glazes, it contributes to the formation of a glassy phase, affecting transparency, color development, and surface texture. The effectiveness of feldspar in these roles is profoundly influenced by its fineness. Ultrafine feldspar particles (typically below 10μm) exhibit higher reactivity, leading to lower firing temperatures, reduced energy consumption, and more uniform microstructures. Achieving this optimal fineness requires precision grinding technology capable of producing controlled particle size distributions without contamination.

Conventional ball mills and Raymond mills present several limitations for modern ceramic production requirements. These include broad particle size distributions, high energy consumption, iron contamination from grinding media, and limited control over top particle size. The inability to consistently produce feldspar powder with a D97 value below 10μm restricts ceramic manufacturers from achieving higher performance standards and exploring innovative formulations.

The evolution of grinding technology has addressed these challenges through innovative mechanical designs, precision classification systems, and intelligent control mechanisms. Modern ultrafine mills utilize principles of material bed comminution and centrifugal classification to achieve unprecedented levels of fineness and efficiency.

Contemporary ultrafine milling systems incorporate several critical advancements: high-efficiency classifiers that enable precise particle size cuts, wear-resistant grinding components that minimize contamination, intelligent control systems that maintain consistent product quality, and integrated dust collection systems that ensure environmental compliance. These technologies collectively enable the production of feldspar powders with tailored particle size distributions specifically optimized for ceramic applications.

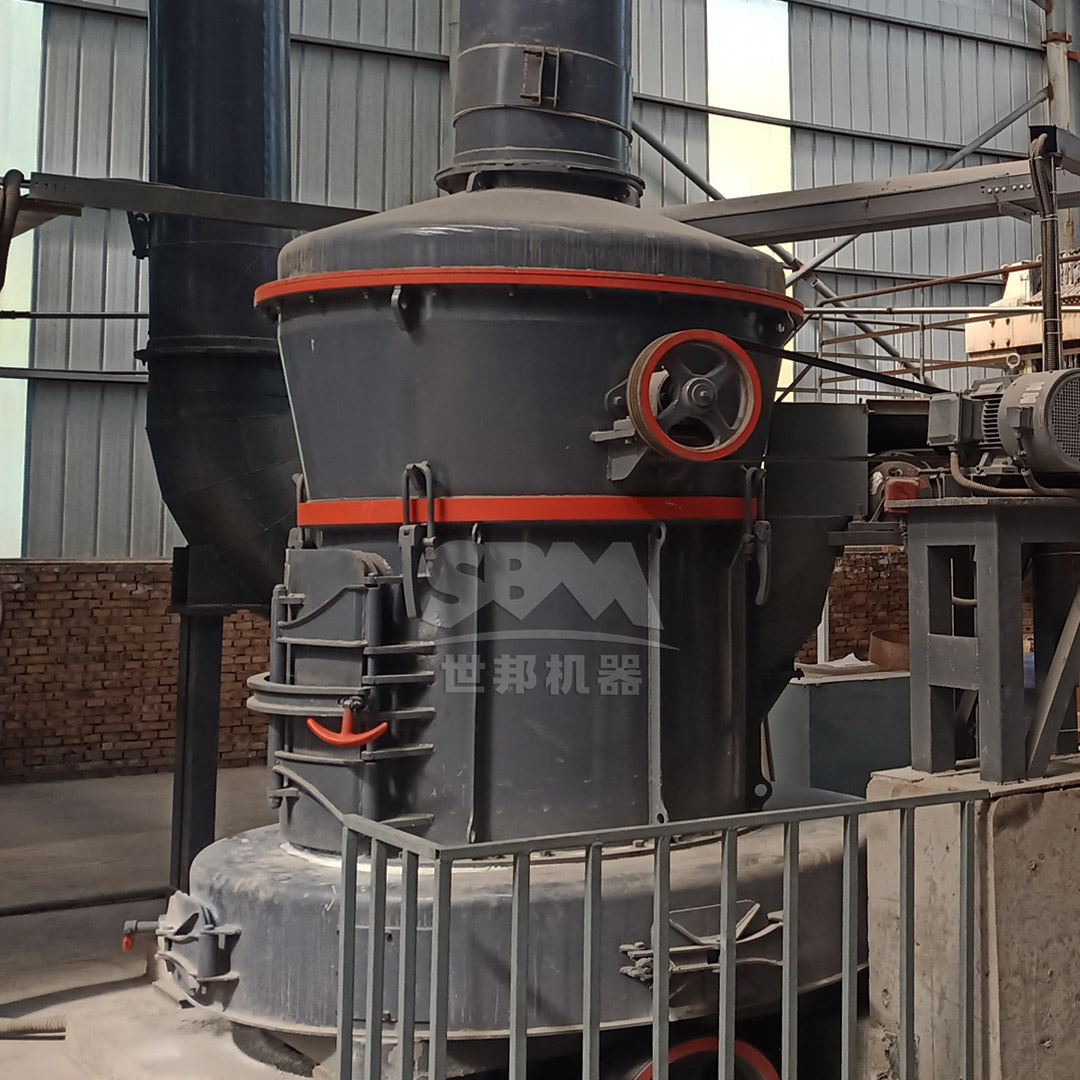

For ceramic manufacturers seeking to optimize their feldspar processing, the SCM Ultrafine Mill represents an ideal solution. This advanced milling system is specifically engineered to produce feldspar powders with the precise characteristics required for both ceramic body and glaze applications.

The SCM Ultrafine Mill processes feldspar with an input size of ≤20mm and delivers output fineness ranging from 325 to 2500 mesh (D97 ≤5μm), with processing capacities from 0.5 to 25 tons per hour depending on the specific model. This capability makes it particularly suitable for ceramic operations requiring consistent, high-purity feldspar powder.

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Output Fineness (mesh) |

|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 325-2500 |

The SCM Ultrafine Mill offers several distinct advantages for ceramic feldspar processing. Its high-efficiency classification system ensures precise particle size control, eliminating coarse particles that can cause defects in ceramic surfaces. The energy-efficient operation (30% lower energy consumption compared to jet mills) significantly reduces production costs. The mill’s durable design with special material rollers and grinding rings extends component life and minimizes metallic contamination—a critical consideration for whiteware and technical ceramics. Additionally, the eco-friendly operation with pulse dust collection efficiency exceeding international standards and noise levels below 75dB creates a better working environment.

The milling process begins with the main motor driving multiple grinding rings to rotate. Feldspar material is fed into the grinding chamber where centrifugal force disperses it to the grinding path. The material undergoes progressive compression and shearing between the rollers and rings, achieving step-by-step refinement. Finally, the powdered product is collected by a cyclone collector and pulse dust removal system, ensuring high recovery rates and minimal product loss.

The use of ultrafine feldspar powder significantly enhances ceramic body performance. Finer feldspar particles distribute more uniformly throughout the clay body, promoting even vitrification during firing. This results in reduced porosity, higher mechanical strength, improved thermal shock resistance, and enhanced dimensional stability. The controlled particle size distribution achievable with the SCM Ultrafine Mill allows ceramic engineers to precisely tailor sintering behavior, potentially lowering firing temperatures by 20-30°C while maintaining or improving final properties.

In glaze applications, ultrafine feldspar powder plays an even more critical role. The particle size directly affects glaze transparency, color development, surface smoothness, and craze resistance. Glazes formulated with feldspar ground to D97 ≤5μm exhibit superior melting characteristics, resulting in more brilliant surfaces with fewer imperfections. The absence of coarse particles eliminates pinholes and orange peel effects, while the high surface area promotes better suspension in glaze slips, reducing settling and application issues.

When compared to traditional ball mills and conventional Raymond mills, the SCM Ultrafine Mill demonstrates clear advantages for ceramic feldspar processing. Ball mills typically produce broader particle size distributions with higher energy consumption and potential iron contamination. Conventional pendulum mills struggle to achieve consistent sub-10μm fineness. The SCM system’s integrated classification technology ensures tight particle size control while its mechanical grinding principle offers significantly higher energy efficiency than jet milling systems.

The economic benefits of implementing advanced ultrafine milling technology extend beyond energy savings. The ability to produce consistent, high-quality feldspar powder reduces formulation adjustments, minimizes production rejects, and enables the development of premium ceramic products with higher market value. The reduced maintenance requirements and extended component life of the SCM Ultrafine Mill further contribute to lower operating costs over the equipment lifecycle.

For ceramic operations requiring feldspar powders in the medium fineness range (30-325 mesh), the MTW Series Trapezium Mill offers an excellent alternative. With an input size of ≤50mm and processing capacity of 3-45 tons per hour, this mill is ideal for larger-scale operations where the ultimate fineness of the SCM series is not required. Its innovative features include wear-resistant shovel design, curved air channel optimization, and integrated cone gear transmission system that achieves 98% transmission efficiency.

Integrating advanced feldspar milling technology requires careful planning. Manufacturers should begin with a comprehensive analysis of their current feldspar specifications and ceramic product requirements. Pilot testing with the target mill using production samples helps establish optimal operating parameters. Successful implementation typically involves staff training on the new technology’s operational principles and maintenance requirements, followed by a phased integration into production processes.

The ceramic industry continues to evolve toward higher performance standards and more sustainable manufacturing practices. Future developments in feldspar processing will likely focus on even greater energy efficiency, digital integration for real-time quality control, and adaptability to a wider range of mineral compositions. The flexibility and precision of modern ultrafine milling systems position them as foundational technologies for next-generation ceramic manufacturing.

The optimization of feldspar processing through advanced ultrafine milling technology represents a significant opportunity for ceramic manufacturers to enhance product quality, reduce production costs, and develop innovative formulations. The SCM Ultrafine Mill, with its precise particle size control, energy-efficient operation, and contamination-free design, offers ceramic producers a powerful tool for achieving competitive advantage in an increasingly demanding market. By embracing these technological advancements, manufacturers can unlock new possibilities in both ceramic body and glaze production, paving the way for higher performance ceramics with improved sustainability profiles.